C00003 | status of last device command, C00005 | application, C00005 – Lenze 8400 motec User Manual

Page 333: C00003, Displays the st, Ication preset in, 11 parameter reference

Lenze · 8400 motec · Reference manual · DMS 4.1 EN · 08/2013 · TD05

333

11

Parameter reference

11.2

Parameter list | C00003

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

C00003

C00005

Parameter | Name:

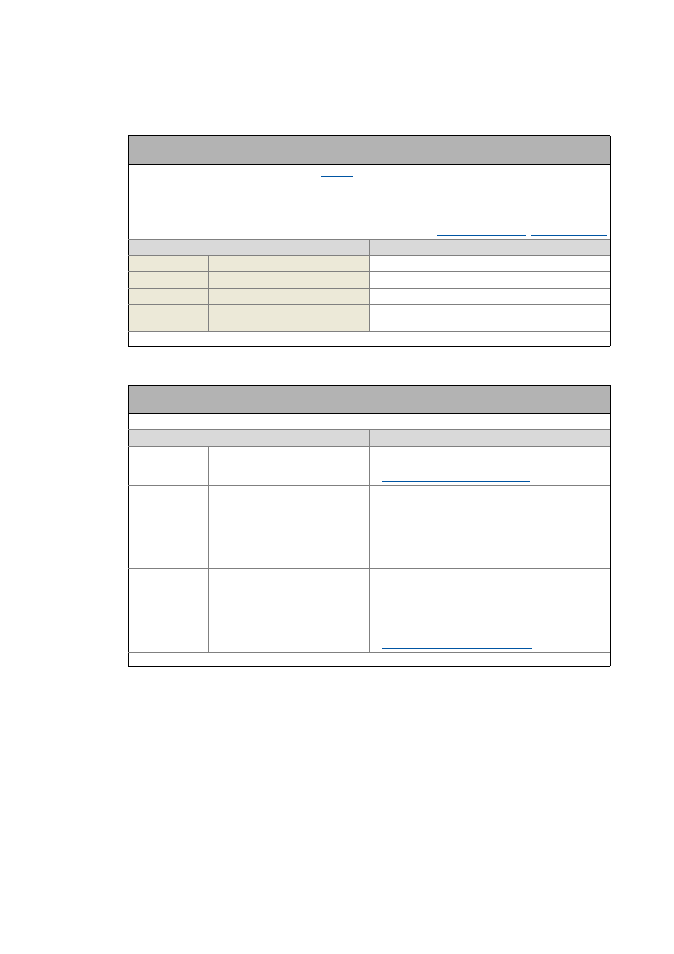

C00003 | Status of last device command

Data type: UNSIGNED_8

Index: 24572

d

= 5FFC

h

Status of the device command executed last (

).

Note:

Before switching off the supply voltage after carrying out a device command, check whether the device command

has been carried out successfully via the status display!

Selection list

(read only)

Info

0 Successful

Device command has been executed successfully.

1 Command unknown

Device command implausible or unknown to the system.

2 No access

Unauthorised access for requested device command.

3 Time-out

Device command could not be processed in the defined

time (timeout).

Read access Write access CINH PLC STOP No transfer COM MOT

Scaling factor: 1

Parameter | Name:

C00005 | Application

Data type: UNSIGNED_16

Index: 24570

d

= 5FFA

h

Selection of the technology application

Selection list

(Lenze setting printed in bold)

Info

1000 Actuating drive speed

This technology application is used to solve speed-

controlled drive tasks, e.g. conveying belts.

Application "Speed actuating drive"

1100 Actuating drive speed (AC Drive

Profile)

From version 04.01.00

Use this application if you use the EtherNet/IP™

Communication Unit. The process data word received

from the master control is then interpreted as "AC Drive

profile" control word.

Detailed information on the "AC Drive Profile" can be

found in the EtherNet/IP™ communication manual.

3000 Switch-off positioning

From version 05.00.00

This technology application is used to solve speed-

controlled drive tasks which require a pre-switch off or

stopping at certain positions, e.g. roller conveyors and

conveying belts. This is implemented by connecting

switch-off sensors.

Application "Switch-off positioning"

Read access Write access CINH PLC STOP No transfer COM MOT

Scaling factor: 1