5motor control (mctrl) – Lenze 8400 motec User Manual

Page 165

Lenze · 8400 motec · Reference manual · DMS 4.1 EN · 08/2013 · TD05

165

5

Motor control (MCTRL)

5.12

Braking operation/brake energy management

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

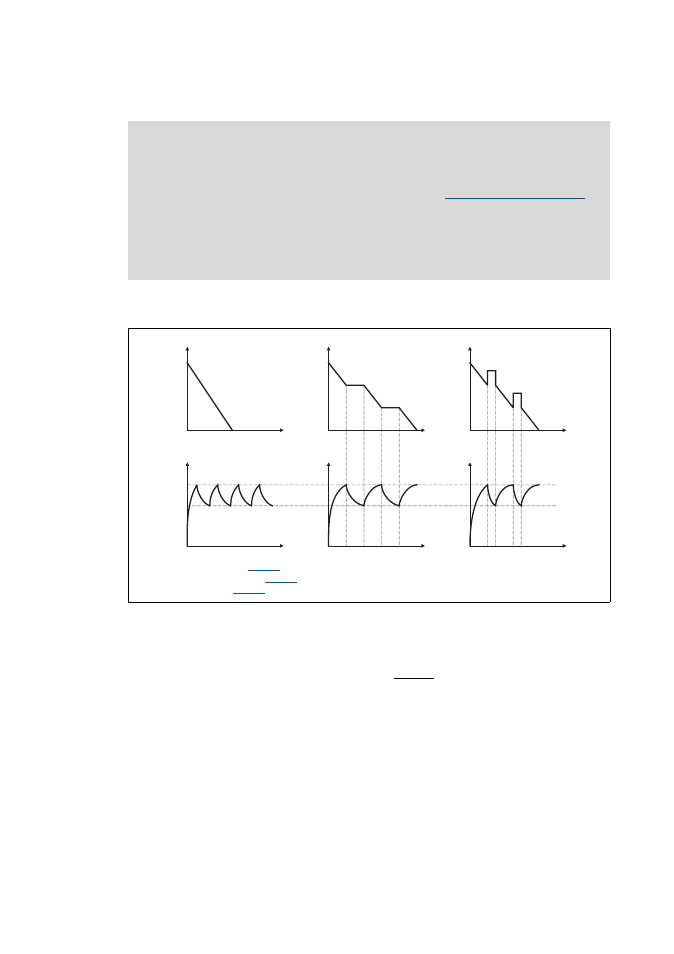

The way in which the different braking procedures work is demonstrated schematically in the

following illustration:

[5-15] Graph of the effective speed setpoint and the DC bus voltage during braking

Tip!

If it is possible to dispense with exact adherence to the deceleration ramp in simple

applications, selection of a braking method without an external brake resistor enables

costs to be reduced due to the avoidance of having to use a brake resistor .

• For the delay time, select a value as high as possible if you are not using an external brake

resistor, and use the S-shaped ramp if possible.

With the "inverter motor brake" function, an effective braking torque of 10 ... 20 % of the

rated motor torque can be achieved.

Stop!

• Both braking methods "Stop of deceleration" and "Inverter motor brake" can only be

used for speed-controlled applications without the influence of a position controller!

• When the "inverter motor brake" function is used, the

is

not adapted. If it is braked too frequently, there is a risk of the motor being thermally

overloaded or the motor overload monitoring does not work properly!

• The "inverter motor brake" function

• must not be used with vertical conveyors (hoists) or with active loads!

• is not available with sensorless vector control.

Use of the brake resistor (

Stopping of the deceleration (

= "2: Brake resistor and stopping of the ramp function generator")

Inverter motor brake (

= "4: Motor brake and ramp stop and brake resistor")

n

Set

t

n

Set

t

1

2

n

Set

t

0

t

t

t

U

DC

U

DC

U

DC