9diagnostics & error management – Lenze 8400 motec User Manual

Page 295

Lenze · 8400 motec · Reference manual · DMS 4.1 EN · 08/2013 · TD05

295

9

Diagnostics & error management

9.7

Maloperation of the drive

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

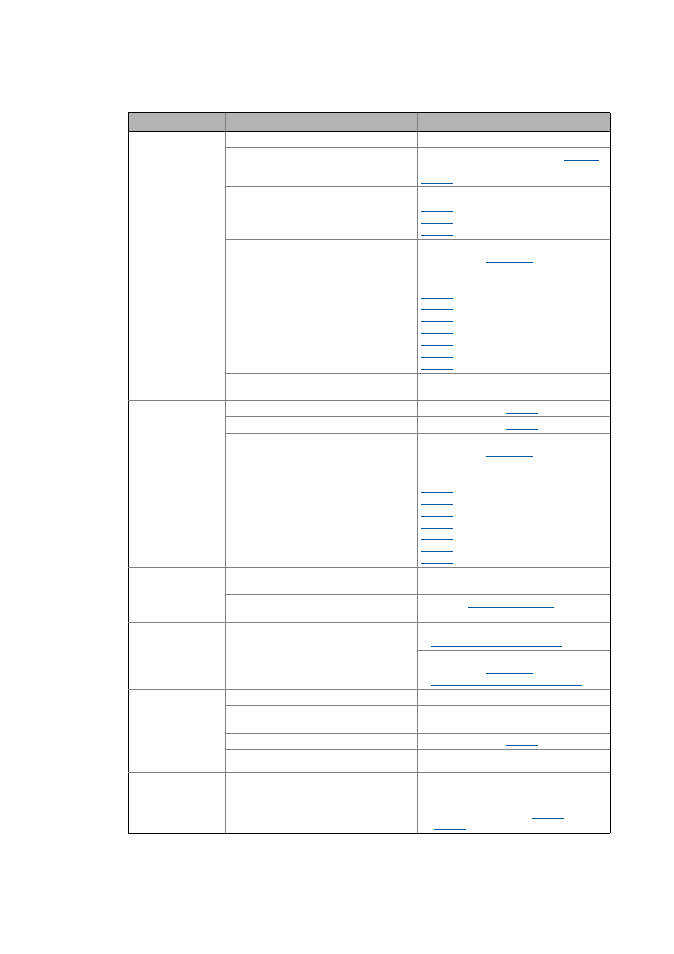

Motor rotates irregu-

larly

Motor cable is defective

Check motor cable

Maximum motor current in motor or genera-

tor mode is set too low

Adjust settings to the application:

Imax in motor mode

: Imax in generator mode

Motor is underexcited or overexcited

Check parameterisation:

: Motor control

: VFC: V/f base frequency

: VFC: Vmin boost

Rated motor data (stator resistance, speed,

current, frequency, voltage) and cos ϕ and/

or magnetising inductance is not adapted to

the motor data

Execute automatic motor parameter identifi-

cation with the

device command

- or -

Adjust motor parameters manually:

: Motor stator resistance

: Rated motor speed

: Rated motor current

: Rated motor frequency

: Rated motor voltage

: Motor cosine phi

: Motor magnetising inductance

Motor windings are wired incorrectly

Reverse from star connection to delta con-

nection

Motor consumes too

much current

V

min

boost has been selected too high

V/f base frequency has been selected too low Correct setting with

Rated motor data (stator resistance, speed,

current, frequency, voltage) and cos ϕ and/

or magnetising inductance is not adapted to

the motor data

Execute automatic motor parameter identifi-

cation with the

device command

- or -

Adjust motor parameters manually:

: Motor stator resistance

: Rated motor speed

: Rated motor current

: Rated motor frequency

: Rated motor voltage

: Motor cosine phi

: Motor magnetising inductance

Motor parameter

identification is

aborted with error

LP1

Motor is too small compared to the rated de-

vice power (>1 : 3)

Use device with lower rated power

DC-injection braking (DCB) is active via ter-

minal

Deactivate

Drive behaviour with

vector control is not

satisfactory

different

Optimise or manually adapt vector control

Sensorless vector control (SLVC)

Execute automatic motor parameter identifi-

cation with the

device command

Automatic motor data identification

Torque dip in field

weakening range

or

motor stalling when

being operated in the

field weakening

range

Motor is overloaded

Check motor load

Motor windings are wired incorrectly

Reverse from star connection to delta con-

nection

V/f base frequency is set too high

Correct setting with

Mains voltage too low

Increase mains voltage

Parameter changes

are not accepted

Settings according to DIP1, DIP2, P1, P2 and

P3 are active (local mode)

Set DIP1/switch 1 to "OFF" in order that no

parameters of the memory module are over-

written when the device is started.

• See display parameters

and

for details.

Maloperation

Cause

Remedy