12 braking operation/brake energy management, Braking operation/brake energy management, 5motor control (mctrl) – Lenze 8400 motec User Manual

Page 163: Stop

Lenze · 8400 motec · Reference manual · DMS 4.1 EN · 08/2013 · TD05

163

5

Motor control (MCTRL)

5.12

Braking operation/brake energy management

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.12

Braking operation/brake energy management

When electric motors are braked, the kinetic energy of the drive train is fed back into the DC circuit

regeneratively. This energy leads to an increase in the DC bus voltage. In order to avoid overvoltage

in the DC bus, several different strategies can be used:

• Use of a brake resistor

• Stopping of the deceleration when the brake chopper threshold is exceeded (HlgStop)

• Use of the "inverter motor brake" function

(from version 02.00.00)

• Overmagnetising the motor

(from version 02.00.00)

• Combination of the above named options

Short overview of the relevant parameters:

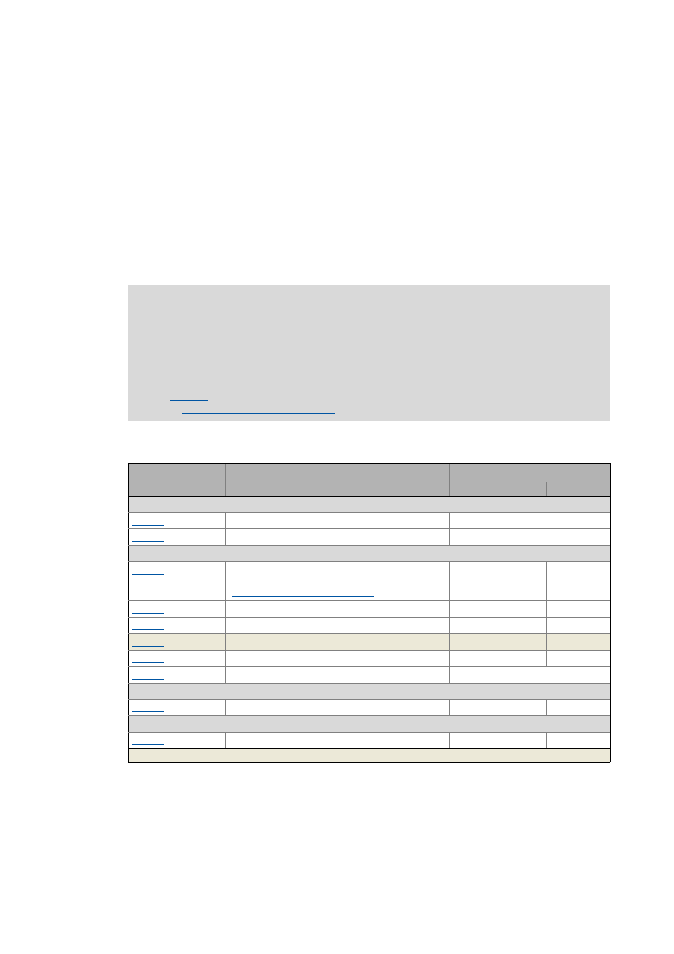

Stop!

If the connected brake resistor

• has a lower brake resistance value than the required brake resistor, the brake chopper

may be destroyed!

• has a too low thermal power dissipation, the brake resistor may be destroyed!

serves to parameterise the error response of the brake resistor monitoring.

Brake resistor monitoring (I2xt)

Parameter

Info

Lenze setting

Value Unit

Basic settings

Mains voltage

3ph 400 V

Resp. to brake resistor control

Brake resistor

Brake resistor

Brake resistance value

(dependent on the device power, see subchapter

"

Settings for internal brake resistor

")

220.0 Ohm

Rated brake resistor power

15 W

Thermal capacity - brake resistor

0.6 kWs

Brake resistor utilisation

- %

Threshold - brake resist. overload

100 %

Resp. to brake resist. overtemp.

Fault

Inverter motor brake (variant 1)

Inverter motor brake: nAdd

80 rpm

Inverter motor brake (variant 2)

Inverter motor brake: Motor flux Add

20.0 %

Highlighted in grey = display parameter