5motor control (mctrl) – Lenze 8400 motec User Manual

Page 167

Lenze · 8400 motec · Reference manual · DMS 4.1 EN · 08/2013 · TD05

167

5

Motor control (MCTRL)

5.12

Braking operation/brake energy management

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

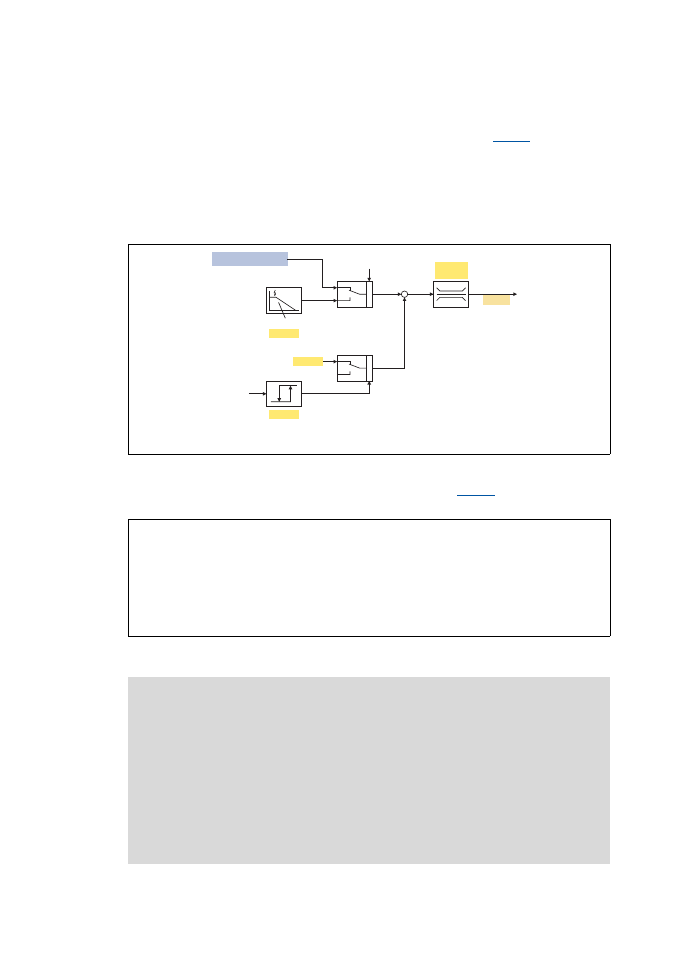

Operating mode of the inverter motor brake

During the deceleration, the speed encoder is stopped. The speed set in

is added to the

speed setpoint by means of a hysteresis-2-point DC-bus voltage controller. Here, the sign of the

current actual speed is considered. Moreover, the speed controller is stopped during overvoltage.

If the DC-bus voltage falls below a defined DC-bus voltage potential of the hysteresis controller, the

applied additive speed is cancelled and the speed encoder is enabled again.

The energy is converted into heat in the motor due to alternating instances of acceleration and

deceleration as a result of this switching operation.

[5-16] Signal flow of the "Inverter motor brake" function

• In case of an asynchronous motor, the additive speed setpoint (

) should be 1 … 4 times

the slip of the machine:

[5-17] Formula for calculating the additive speed setpoint for an asynchronous motor

DC-bus voltage

Speed setpoint for motor control

0

1

nSpeedSetValue_a

C00105

C00050

C00909/1

C00909/2

C00173

0

1

C00987

0

QSP ramp

QSP

D

n

Set,Add

p = number of pole pairs

n

Rat

= Rated speed of the motor

f

Rat

= Rated frequency of the motor

n

Sync

= Synchronous speed of the motor

C00987 [rpm]

1 ... 4 n

Sync

[rpm] n

Rated

[rpm]

–

(

)

⋅

=

n

Sync

[rpm]

f

Rated

Hz 60

⋅

p

--------------------------------

=

Note!

When the "inverter motor brake" function is used, torque oscillations occur which have

may have a negative effect on the service life of the components of the mechanical drive

train (e.g. gearbox).

• The extent of the occurring oscillations depends on the drive train (mass inertia,

natural frequencies, etc.) and the function setting.

• We recommend optimising the "inverter motor brake" function for an oscillation-free

operation as described in the following. Usually, this setting does not cause any

torque oscillations which affect the service life of the gearbox.

• The settings of implementing a maximum acceleration ramp are only recommended

if the inverter motor brake is used infrequently (e.g. in case of quick stop).