4 ta "switch-off positioning, Ta "switch-off positioning, 7technology applications – Lenze 8400 motec User Manual

Page 238

7

Technology applications

7.4

TA "Switch-off positioning"

238

Lenze · 8400 motec · Reference manual · DMS 4.1 EN · 08/2013 · TD05

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.4

TA "Switch-off positioning"

This function extension is available from version 05.00.00!

The basic principle of this technology application is to travel to a switch-off sensor (e.g. a limit

switch) in a speed-controlled manner and to stop as close as possible at this position. Unlike other

positioning controls, the switch-off positioning neither has a position feedback nor calculates the

path in advance. Thus, the accuracy that can be achieved depends on various factors such as the

speed at which the switch-off sensor is advanced.

In addition, a pre-switch off can be implemented which requires a sufficient number of unassigned

digital inputs on the controller which can be used to connect other sensors for the additional stop

positions. These sensors effect a reduction in speed before the last switch-off sensor is reached.

Features

• Pre-configured control modes for terminals and bus control (with predefined process data

connection to the fieldbus)

• Free configuration of input and output signals

• Offset and gain of the main setpoint (if defined via analog input)

• Up to 3 fixed setpoint for speed

• Adjustable setpoint ramp times

• Linear or S-shaped ramp type

• Automatic holding brake control

• Quick stop (QSP) with adjustable ramp time

• Load monitoring

• Implemented and freely available "GeneralPurpose" functions:

Counter, binary delay element, binary logic, analog comparison

• Integration of encoder feedback

• Switch-off sensor management for the implementation of a pre-switch off

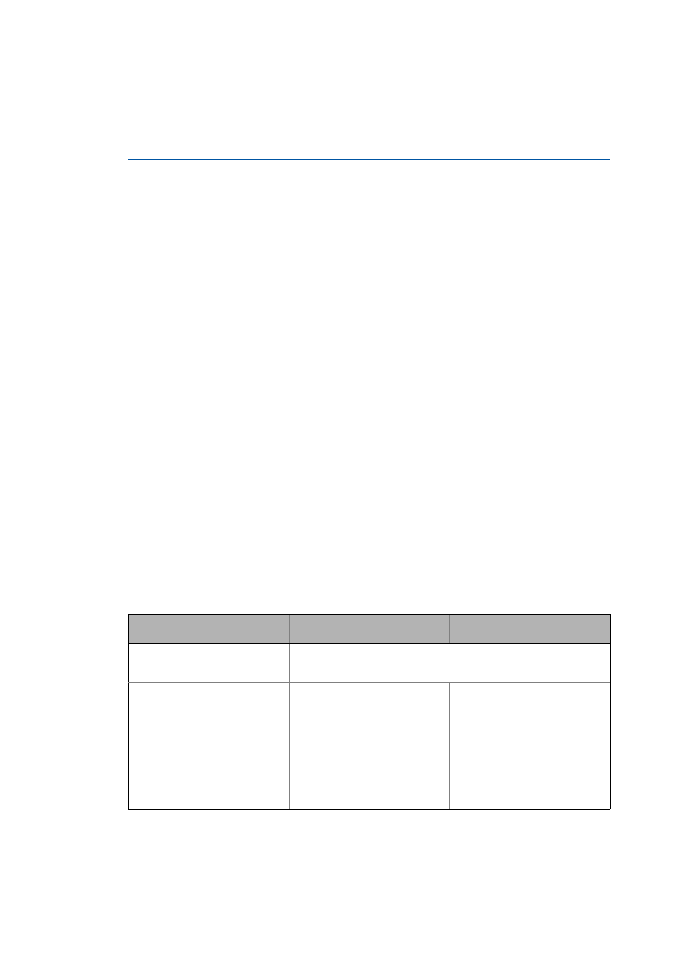

Decision criteria

Criteria

Switch-off positioning with constant

load

Switch-off positioning with variable

load

Operating mode

V/f characteristic without speed sensor.

Alternatively for large breakaway torques: Use of a sensorless vector control

(only applicable for horizontal movements).

Limit switch evaluation

One limit switch is required per

direction of movement.

When the limit switch is reached, the

drive is brought to a standstill leaded

by the deceleration ramp or the QSP

ramp.

One limit switch and an initiator for

quick/slow switch-over is required

per direction of movement.

When the initiator is reached, the

speed of the drive is reduced to

creeping speed (fixed setpoint 2) in a

controlled way.

When the limit switch is reached, the

drive is brought to a standstill leaded

by the deceleration ramp or the QSP

ramp.