Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 860

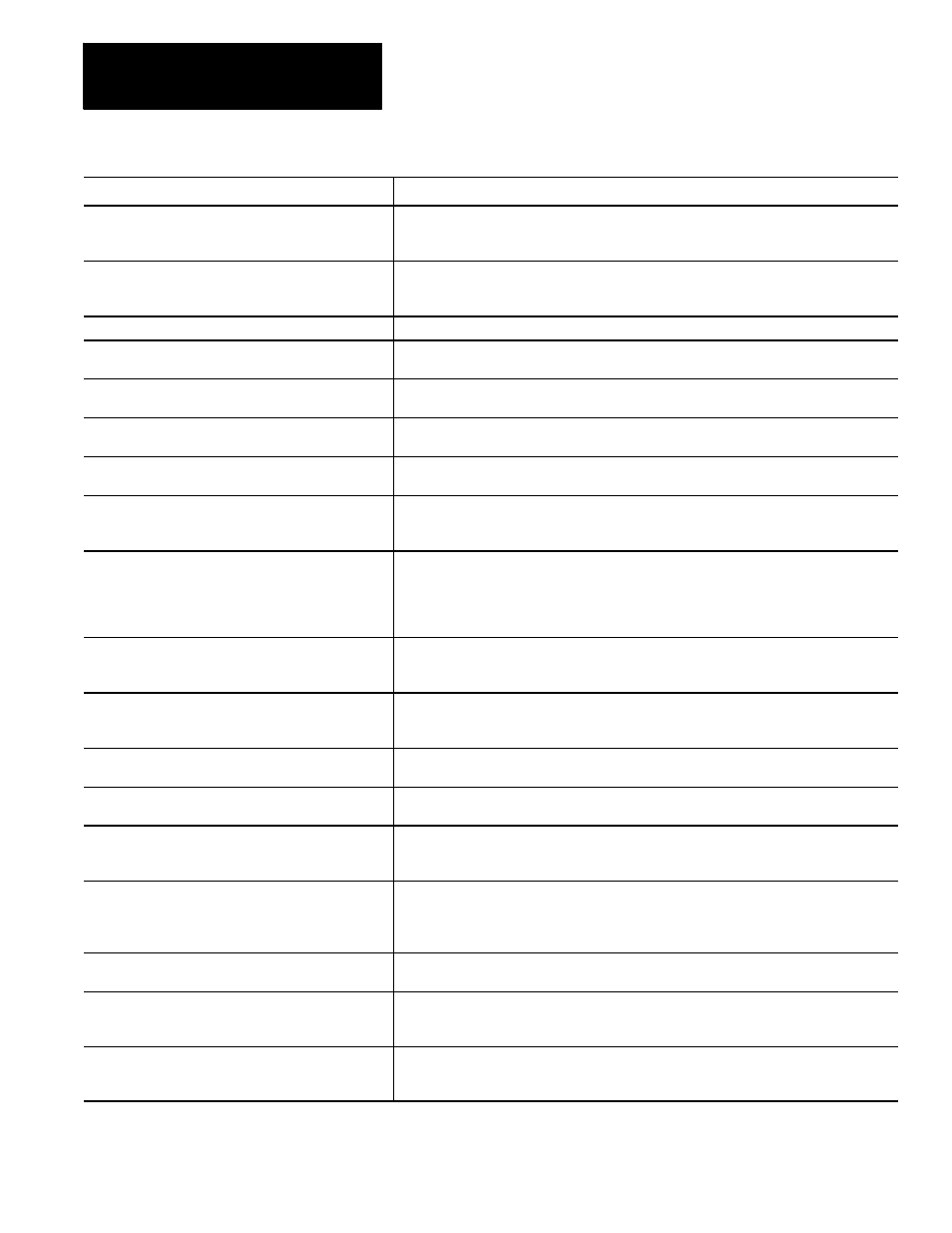

Error and System Messages

Section 16

16-40

Message

Description

SERVO BUSY DURING HOMING OPERATION

This error indicates that the servo processor was unable to respond during a homing operation.

It can occur under the unusual condition resulting from two or more servo axes reaching their

home point simultaneously. Generally, the axes can be re-homed with no problems.

SERVO CONFIGURATION ERROR

The AMP servo configuration is inconsistent. An example of this error would be if the

downloaded AMP file were configured for only two axes, when the AMP parameter “Number of

Motors on First Board”was set for three.

SERVO COMMUNICATIONS ERROR

A communications error occurred between the control and the servo module.

SERVO CURRENT LOOP ERROR

While running an axis, the allowable current loop proportional error or current loop integral error

has gone out of range.

SERVO INTERFACE FAILURE

The servo interface diagnostics performed on power-up have failed. Attempt to power up again.

If the error remains, contact Allen-Bradley customer support services.

SERVO POS & VEL FB SIGN ERR

This is a power turn-on error which occurs when the signs of the position and velocity feedback

devices do not match when a common feedback port is used for both.

SERVO POWER UP SEQUENCE ERROR

The servo processor diagnostics performed on power-up have failed. Attempt to power up

again. If the error remains, contact Allen-Bradley customer support services.

SERVO POWERUP DIAGNOSTICS FAILURE

The servo module diagnostics performed on power-up have failed. Possible causes include

incorrect servo AMP parameters being downloaded. An example would be configuring AMP for

five axes when there is only one servo module installed.

SERVO PROCESSOR ASSIGNMENT ERROR

Too many servos were AMPed or a servo was assigned to a non-existent servo processor. The

system is held in E-Stop. The message indicates an error in the total number of fitted axes and

spindles, or in the AMPed values of:

Number of Motors on 1st board

Number of Motors on 2nd board.

SERVO PROCESSOR OVERLAP

The analog version of the servo sub-system provides fine iteration overlap detection. This

message is displayed if the fine iteration software on the DSP does not execute to completion in

one fine iteration.

SERVO PROM CHECKSUM ERROR

The checksum test on the servo processor software stored in PROM memory has failed. This

test is performed on power-up and periodically while the system is running. Contact

Allen-Bradley customer support services.

SERVO PTO DIAGNOSTICS FAIL

The servo card has failed its power-up diagnostics. Consult Allen-Bradley customer support

services.

SERVO PTO SEQUENCE ERROR

The servo card has failed its power-up diagnostics. Consult Allen-Bradley customer support

services.

SERVO TIME-OUT READING ABSOLUTE ENCODER

During power-up initialization of the position registers or during a homing operation, the servo

processor has failed to return a read within the required time after the absolute position has

been requested by the main processor. Consult Allen-Bradley customer support services.

SERVO TIME-OUT READING FEEDBACK

During a homing operation, if there is an error reading feedback from the servo module, this

message appears. This usually occurs when the system scan time is close to the threshold at

which PAL execution can just complete and when homing more than 3 axes at a time. This

error can be avoided by homing axes individually or increasing the system scan time in AMP.

SET ZERO NOT ALLOWED ON:

A set zero operation on the specified axis is not permitted. Typically this is because either the

control is not in manual mode, or the selected axis is in the process of being jogged.

SHAFT VALUE > NUMBER OF POCKETS

An attempt was made to assign a shaft pocket that is greater than the number of pockets

assigned for that custom tool. The shaft pocket number must be a value between 1 and the

number of pockets assigned to that tool.

SHARED AXIS CONFIGURATION ERROR

Either there are too many shared axes configured, a shared axis has the same name as some

other axis in the system, the diameter axes on a lathe are shared axes, or some other

miscellaneous configuration error occurred.