Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 827

Error and System Messages

Section 16

16-7

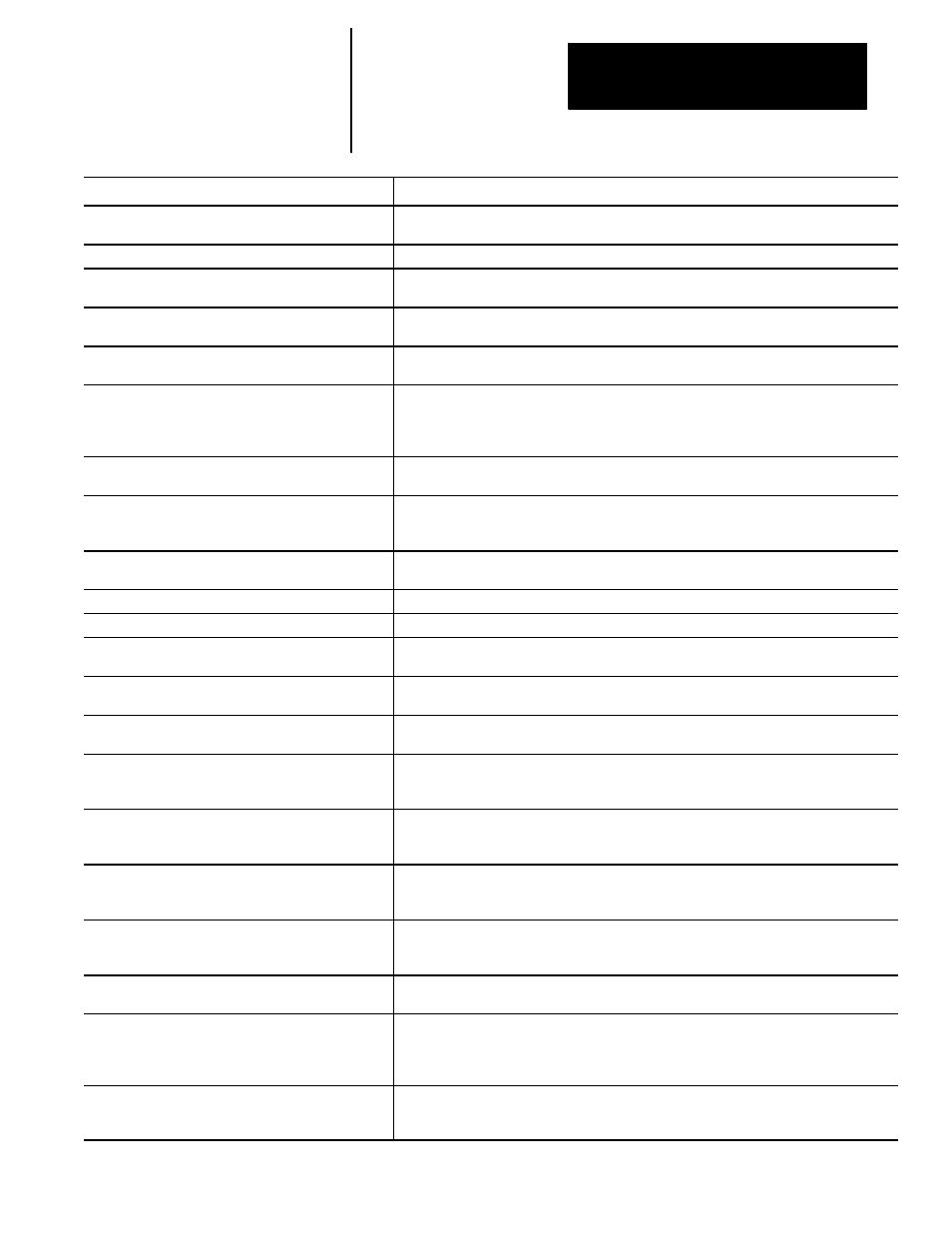

Message

Description

CANNOT READ A WRITE-ONLY PARAMETER

An attempt was made to use the value of a paramacro system parameter that is a write-only

parameter. This parameter may have only its value written to. It cannot be read.

CANNOT READ DIRECTORY

This indicates a serious RAM disk problem. If retry doesn’t work, you may have to reformat.

CANNOT READ PROGRAM

This indicates a serious problem with the program. If retry doesn’t work, you may have to delete

the program.

CANNOT RENAME

When performing a rename of a program name, the new program name has not been correctly

entered. The format is OLD PROGRAM NAME,NEW PROGRAM NAME.

CANNOT REPLACE START POINT

An illegal attempt was made to change the axis calibration start-point using the online AMP

feature.

CANNOT RESTART G24 HARD STOP

An attempt was made to restart a part program on a block which would have an axis at the hard

stop. You cannot restart or mid start a part program after if (at that blocks execution) any axis

would be holding against a hard stop. You must either re-start/mid--start to a block before the

G24 hard stop block or to a block after the hard stop is released.

CANNOT SEND AVAILABLE COMMAND

This is displayed when a non-programmed communications command is executed from

“send’¨softkey.

CANNOT SET DATA WHEN TOOL IS ACTIVE

An attempt was made to manually (using the softkeys) change tool management data for the

currently active tool. Tool management data can be changed only for a tool that is not currently

selected as the active tool.

CANNOT TAP IN CSS

You must disable the CSS feature before you begin a tapping operation. Disable CSS using a

G97 command.

CANNOT TAP IN VIRTUAL-C MODE

You attempted to use the solid tapping feature while cylindrical or end-face milling was active.

CANNOT UPLOAD - PAL NOT IN PROM

PAL can be uploaded only from the PAL PROMs. PAL in RAM memory cannot be uploaded.

CANNOT UPLOAD - PAL SOURCE NOT LOADED

When the source is loaded, PAL can be uploaded in the 9/240 only . The 9/260 and 9/290

always have PAL in flash.

CANNOT USE COPY WITH ACTIVE TOOL OFFSET

An attempt was made to copy offset data from one axis to another using the {COPY OFFSET}

softkey. You cannot use this softkey if the tool offsets are active.

CANNOT USE EXIT - BLOCK NOT FOUND

An attempt was made to {EXIT} while searching for a block for a mid-program start. You cannot

use {EXIT} until the block has been found. To abort the search, use {QUIT}.

CANNOT WRITE A READ-ONLY PARAMETER

An attempt was made to assign a value to a PAL or system paramacro parameter that is a

read-only parameter. The value of these parameters can be used only by the programmer; they

cannot be altered in the program.

CANNOT WRITE TO PROGRAM

This indicates a serious problem with the program. Attempt to write to program a second time.

If retry doesn’t work, you may have to delete the program. Typically this error is not caused by a

programmer or operator action, but rather by an internal program software error.

CAUTION! YOU ARE IN 7300 TAPE MODE

TO RETURN TO STANDARD 9/240 MODE

RESET THE 7300--COMPATIBILITY PAL FLAG

The operator is cautioned that the tape being copied is presumed to be a 7300 formatted tape.

This message is displayed on the copy-tape set-up screen when the MCU is in 7300

compatibility mode.

CC/TTRC ON, CAN’T ASSIGN TIME DEP. PARAM

An attempt was made to assign a time-dependent paramacro system parameter while

dresser/wheel radius compensation was active. Time-dependant parameters are any system

parameters that record or reference a current axis position.

CHAMFER LENGTH/RADIUS TOO LARGE

A chamfer or radius value programmed with a ,C or ,R would generate a chamfer or radius that

is larger than one or both of the two adjacent tool paths.

CHAMFER/RADIUS NOT ALLOWED

An attempt was made to perform a chamfer or radius cut (programmed with a ,R or ,C) in a

block that does not allow these functions to be performed. For example, you cannot do a

chamfer or radius cut in a non-motion block, in the last block on an MDI line, or in the last block

of a part program.

CHANGE NOT MADE IN BUFFERED BLOCKS

Changes to the offset table did not affect those program blocks that were already in the control’s

current activation queue. Program blocks that call for offsets and which follow those already in

the activation queue will call the updated offset tables.