Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 847

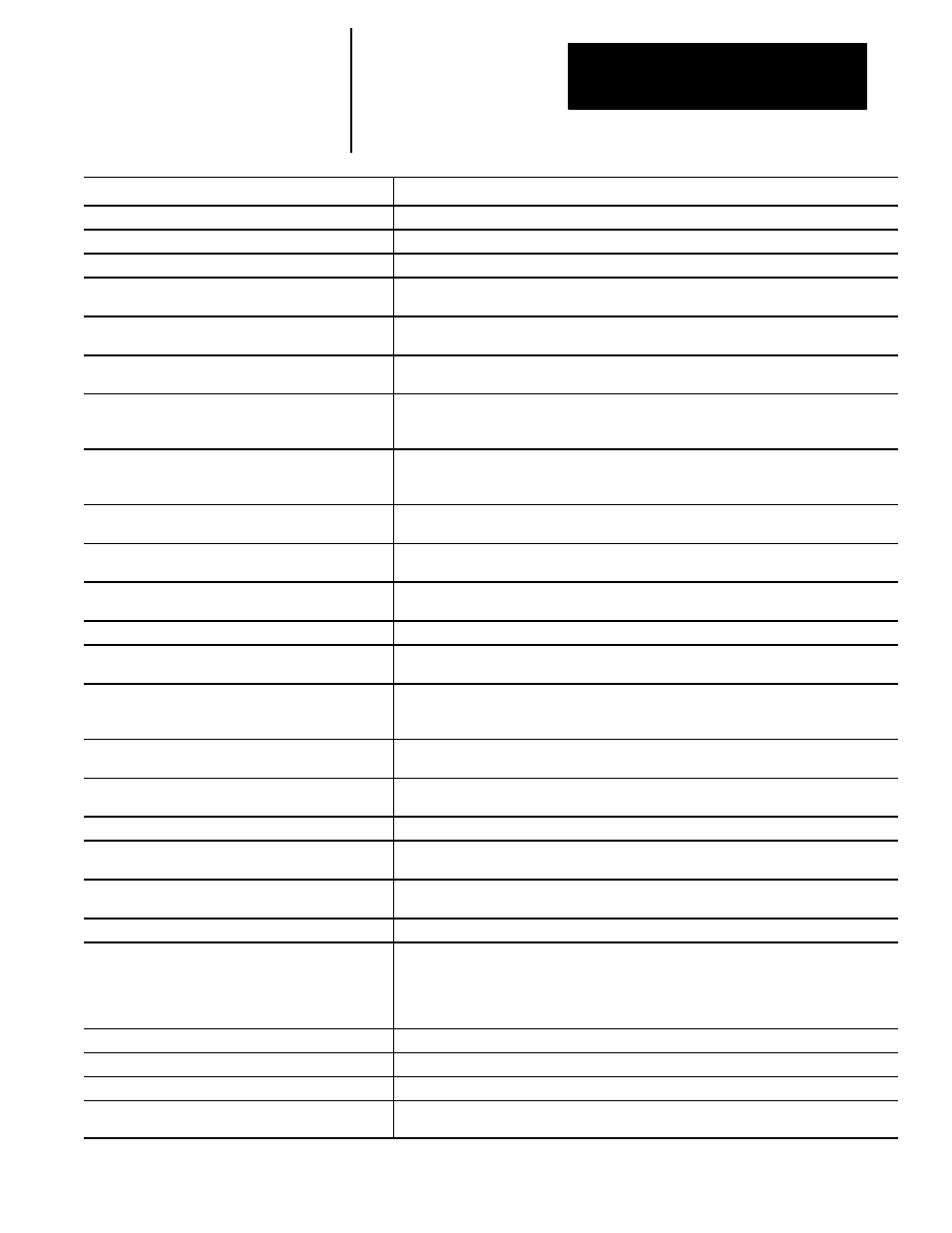

Error and System Messages

Section 16

16-27

Message

Description

MISSING CUTTER COMP CODE

Cutter compensation must be activated before initiating a G89 irregular pocket cycle.

MISSING DATA FROM BLOCK

G89 irregular pocket cycle parameters are missing from a the G89 programming block.

MISSING END PARENTHESIS

An error occurred in G05 DH+ communications block.

MISSING G67

An active modal macro (G66 or G66.1) was not canceled by a G67 before the control read an

M02 or M30 end-of-program command.

MISSING HPG FROM I/O RING

The I/O assignment file that was compiled and downloaded with PAL defines an HPG that is not

physically present in the I/O ring. Verify that the HPG address settings are correct.

MISSING I/O RING DEVICE

The I/O assignment file that was compiled and downloaded with PAL defines an I/O ring device

that is not physically present in the I/O ring. Verify that all device address settings are correct.

MISSING INTEGRAND/RADIUS WORD

A circular or helical block has been programmed with axis data and no radius (R) or integrand (I,

J, or K) values. A radius or integrand must be programmed in a circular or helical block to

define the location of the arc center.

MISSING KEYBOARD AND HPG FROM I/O RING

The I/O assignment file that was compiled and downloaded with PAL defines a keyboard and an

HPG that is not physically present in the I/O ring. Also verify that the keyboard and HPG

address settings are correct.

MISSING KEYBOARD FROM I/O RING

The I/O assignment file that was compiled and downloaded with PAL defines a keyboard that is

not physically present in the I/O ring. Verify that the keyboard address settings are correct.

MISSING L-WORD

The L-word parameter is missing from the G88.5 or G88.6 hemispherical pocket programming

block.

MISSING M02 OR M30

The control has executed through to the last block of a program and has not read an

end-of-program command (M02 or M30).

MISSING MASTER AXIS NAME

Slave axes that do not have a master have been configured for a dual group.

MISSING OR ILLEGAL L-VALUE

An attempt was made to program an irregular pocket milling cycle (G89) with a missing or illegal

L-word.

MISSING PROGRAM NAME

An operation, such as a copy or rename, was performed without the proper program names

being specified. The proper format consists of the program performing the operation followed by

a comma and the target program (OLD PROGRAM NAME,NEW PROGRAM NAME).

MISSING PROGRAM NUMBER (P)

No sub-program name was specified in a block that calls a sub-program or paramacro. A

sub-rogram name must be programmed with a P-word in the calling block.

MISSING PROMPT DATA

The control is waiting for data to be entered on the input line (line 2 of the CRT) using the keys

on the operator panel.

MISSING Q-WORD

The Q-word parameter is missing from the G88 or G89 programming block.

MISSING QPP ANGLE WORD

The second block of a two block QPP set does not contain the necessary angle word to define

an intersection with the first block.

MISSING ROUGHING CYCLE (P/Q) WORD

A roughing cycle block was programmed that does not contain both a starting and ending

sequence number for the contour blocks as programmed with the P- and Q-words.

MISSING ROUGHING CYCLE DEPTH (D) WORD

A roughing cycle block was programmed that does not contain the D parameter for depth of cut.

MISSING SHADOW RAM

Either your 9/290 control is missing the SIMMS necessary for shadow RAM, or your 9/260

control is not equipped with enough RAM to operate properly. If your 9/260 system contains

both the DH+ module and the search monitor utility, additional RAM must be installed. All 9/290

controls must have this additional RAM. Refer to your 9/Series installation and maintenance

manual for details on installing SIMMS.

MISSING SLAVE INCREMENTAL AXIS NAME

When using dual axes on Lathe A, all slave axes must have incremental axis names.

MISSING START PARENTHESIS

An error occurred in G05 DH+ communications blocks.

MISSING TOOL ENTRY

This is missing a tool entry.

MODULE(S) WITH INCONSISTENT REVISION LEVEL

Retry the update utility. If this does not work, call Allen-Bradley and request a new update utility

that matches your hardware revision level.