Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 822

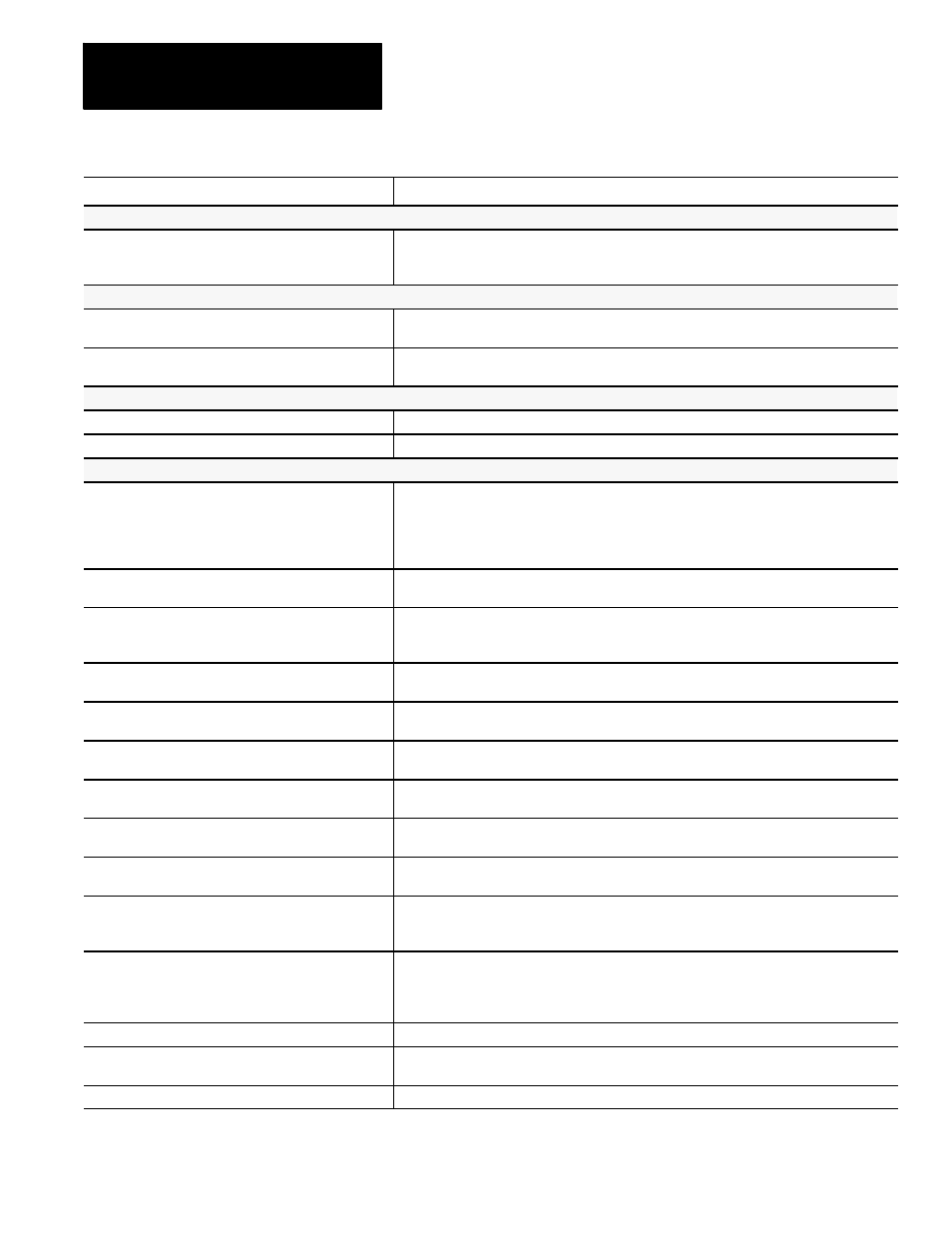

Error and System Messages

Section 16

16-2

Message

Description

2

2MB RAM IS BAD/MISSING

The control has discovered the RAM SIMMs for the two megabyte extended storage option are

either damaged or missing. The RAM SIMMs must be installed or replaced. Contact your Allen

Bradley sales representative for assistance.

9

9/SERIES LATHE - CANNOT USE MILL AMP

The control was powered up with a lathe software option chip installed, when the AMP file that

was downloaded was configured for a mill.

9/SERIES MILL - CANNOT USE LATHE AMP

The control was powered up with a mill software option chip installed, when the AMP file that

was downloaded was configured for a lathe.

7300

7300 NAMES TABLE IS CORRUPTED

7300 program name doesn’t match corresponding name in cross-reference table.

7300 PATTERN NAME TOO LONG

More than 5 digits have been used in the pattern name.

A

A RETRACE BUFFER WAS DELETED

The control required one (or more) of the block retrace buffers to perform a necessary block

look-ahead operation (refer to block look-ahead in the user’s manual). When this occurs, less

block retrace operations can be performed than AMP is configured to allow. If this error occurs,

to improve control efficiency, it is recommended that the number of allowable block retrace

blocks set in AMP be lowered or add additional RAM to you system.

ABS POSITION NOT INITIALIZED

This message indicates that axes with absolute encoders have not been homed. These axes

require an initial homing operation to establish the absolute position.

ABSOLUTE FEEDBACK FAILURE

The control has detected a loss of feedback from the absolute encoder. The most likely cause

of this error would be a broken or disconnected wire. Axis homing may be required after the

error condition is corrected.

ACC/DEC CONFIGURATION ERROR

An axis configuration error was detercted by the control when manual acc/dec was requested in

a program block.

ACCUM. AND EXPECTED LIFE ARE 0

No tool life data was entered for the current tool selected by the tool life management feature.

Tool life management will be disabled for this tool.

ACTIVE GROUP CANNOT BE DELETED

An attempt was made to delete a tool group in the tool life management feature that contains an

active tool currently in the tool holder.

ACTIVE OFFSET CANNOT CHANGE

An attempt was made to alter a tool offset value of a tool offset that is currently the active tool

offset on the control. The active tool offset is indicated with an * on the tool offset table.

ACTIVE TOOL CANNOT BE CHANGED

An attempt was made to edit tool data for the currently active tool. De-activate the tool before

editing.

ACTIVE TOOL CANNOT BE DELETED

An attempt was made to delete tool data for the currently active tool. De-activate the tool before

editing.

ADAPTIVE FEED MAX LIMIT

The actual torque is less than the desired programmed torque and the adaptive feed axis has

reached the programmed maximum feed limit. Either raise the programmed maximum feed

limit, or lower the programmed desired torque.

ADAPTIVE FEED MIN LIMIT

This message indicates your are exceeding the programmed desired torque. The actual torque

is greater than the desired programmed torque and the adaptive feed axis has reached the

programmed minimum feed limit. Either raise the programmed desired torque or lower the

minimum feed limit.

ADAPTIVE FEED PROGRAMMING ERROR

E and Q must both be programmed in every G25 block.

ALL DUAL AXES ARE PARKED

An attempt was made, while using dual axes, to move the dual group when all the axes of that

group were parked.

AMP FILE SIZE ERROR

The size of the AMP file being downloaded is incorrect. The file cannot be downloaded.