Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 206

Section 4C

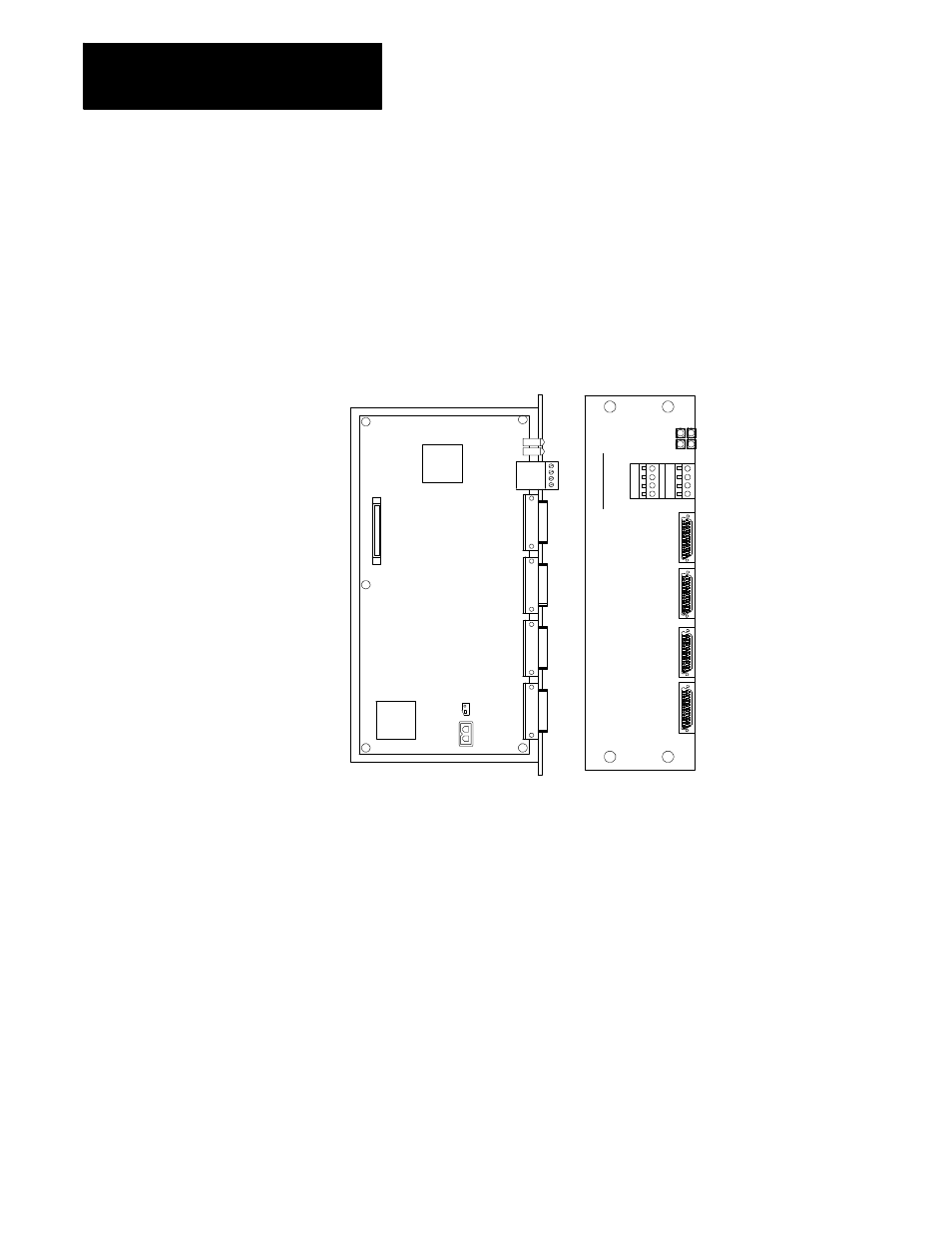

Connecting the 4-axis Servo Module

4C-8

The Analog/1394 Servo Module is mounted in the component enclosure.

It functions as a high-speed servo processor. The control sends positioning

and velocity data to the servo module, which processes the data to generate

the necessary analog drive signals. These signals are sent to the analog

servo amplifiers, which power the servo motors of the control. Each

analog servo module may control up to four closed loop axes and one open

loop axis (typically used for a spindle).

Figure 4C.6

Analog Servo Module

P1

(CN1)

J1

J2

J3

J2

J3

J4

J1

P3

P2

J4

TB1

TB2

TO

UC

H

PR

O

BE

AN

AL

O

G

O

UT

1

3

2

4

FL

T

The servo module receives position data from the axis feedback devices.

It combines this position feedback data with the interpolated commands

from the control to generate the command signals that it outputs to the

servo amplifiers.

The functions of the analog servo module are designed to make the

servomotors run with optimum performance. The maximum feedrates are

be limited by the mechanical abilities of the machine. System gain and the

maximum allowable following error also limit the feedrates. These limits

are entered as AMP parameters. Refer to your AMP reference manual for

more information.

4C.4

Analog/1394 Servo Module

(8520-SM4)