Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 653

Section 13A

Connecting 8520 Digital Drive Systems

13A-19

For 300% of motor rated current, the following jumpers are open:

- AXIS 1: J5, J6, J11, J12 AXIS 2: J17, J18, J23, J24

- AXIS 3: J29, J30, J35, J36

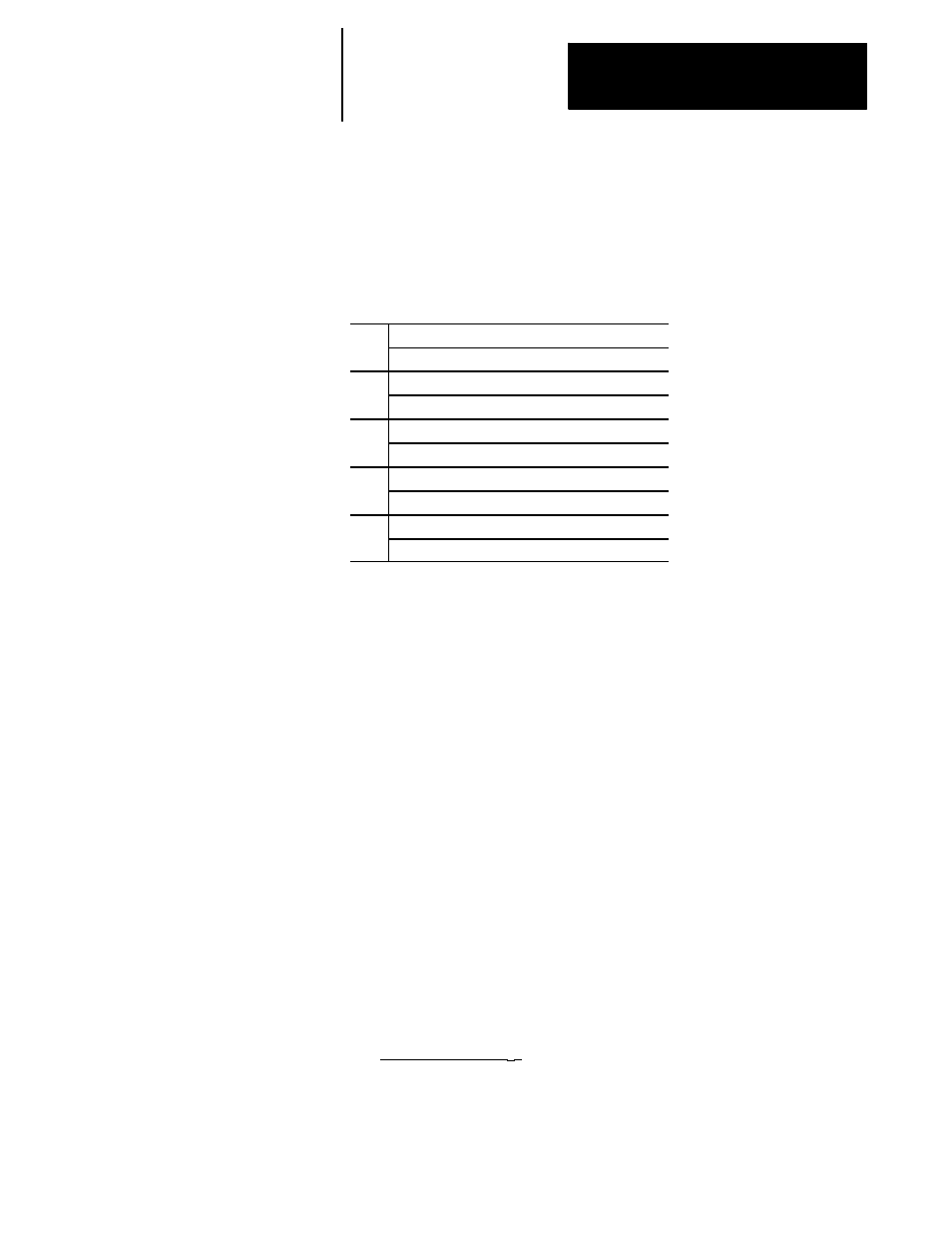

Table 13A.L

3AX-D Servo Amplifier Jumper Settings

(continued)

J37 Short -- Enable Axis 1 Motor

Open -- Disable Axis 1 Motor

J38 Short -- Enable Axis 2 Motor

Open -- Disable Axis 2 Motor

J39 Short -- Enable Axis 3 Motor

Open -- Disable Axis 3 Motor

J40 Short -- Bus Under Voltage FAULT not Latched

Open -- Bus Under Voltage FAULT Latched

J41 Short -- Internal Shunt Resistor Used

Open -- External Shunt Resistor Used

When the servo amplifier is installed as recommended and E-STOP occurs,

the control sets the velocity command to zero. If the axes are in motion at

that time, they will coast to a stop rather than being rapidly decelerated as

they would be under servo amplifier control.

To improve axis stopping time when E-STOP occurs, the 8520 digital

servo amplifier employs a dynamic brake. This brake is in the form of a

power resistor that is shunted across the motor terminals. Power generated

by the motor is dissipated through this resistor, thereby driving the motor

to a rapid stop even though the 8520 digital servo amplifier is off.

There are three shunt resistor options that can be used with the 8520 digital

servo amplifiers. One involves using the internal shunt resistor supplied

with the amplifiers, while the others require purchase and installation of an

external shunt resistor.

The following equations should be used to size a shunt resistor for the

desired application. First, use these equations to solve for the peak power

P, and the average power W. Then apply those values to the chart below to

determine the appropriate shunt option.

P = (.00054) (J) (N

2

)

W = (.0000108) (J) (N

2

)

(T)

13A.6

8520 Digital Servo Amplifier

Shunt Specifications