Connecting the 4-axis servo module – Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 199

Section

4C

4C-1

Connecting the 4-axis Servo Module

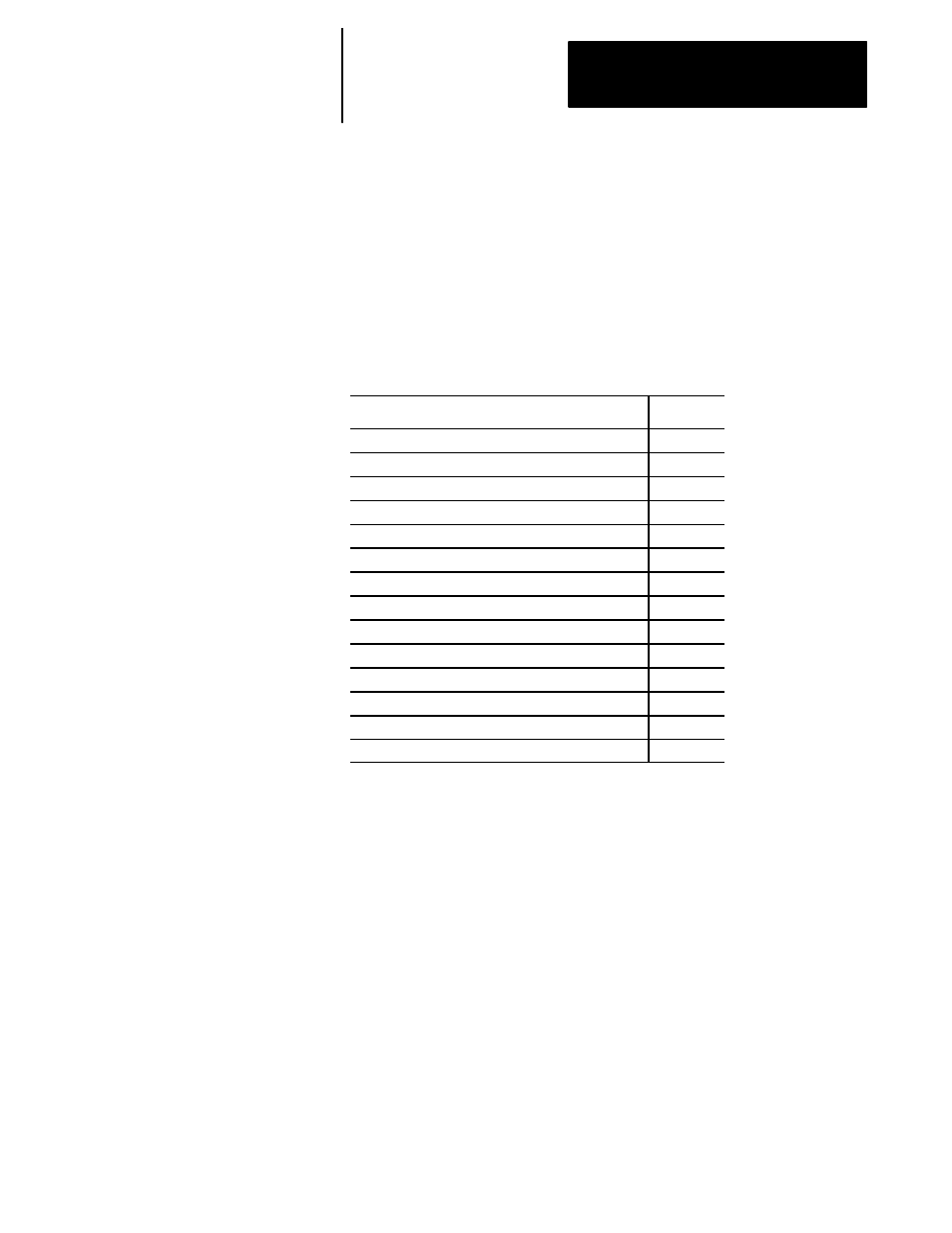

This section covers the integration of the 4-axis analog/1394 and digital

servo module components. A section is devoted to each of the following

drive components:

For Information:

See Page:

How the Digital Servo Card Works

4C-1

Digital Servo Module (8520-ENC4)

4C-4

How the Analog/1394 Servo Card Works

4C-5

Analog/1394 Servo Module (8520-ENC4)

4C-8

Connecting Axes to the Servo Module

4C-9

Servo Module Connectors and Pin Assignments

4C-9

8520-ENC4 Servo Module Specifications

4C-15

8520-SM4 Servo Module Specifications

4C-16

Servo Module Battery Replacement

4C-17

Servo Module LED Indicators

4C-19

Servo Module Test Points

4C-19

Encoder Termination Panel

4C-20

Feedback Devices

4C-21

Wiring a Touch Probe to the Servo Module

4C-27

There are two typical digital servo drive configurations for the control.

The typical mill configuration has 3-axes, each having a servo motor and

feed back device, and a 1-axis analog open loop spindle motor. The typical

lathe configuration has 2-axes, each having a servo motor and feedback

device, and a 1-axis analog open loop spindle motor with position

feedback.

The servo module functions as a high speed servo processor. It is installed

in the component enclosure. The digital servo amplifier translates

low-level PWM signals from the servo module to the power levels

necessary to drive the servo motors.

Current feedback data is read from the current sensors in the digital servo

amplifier and returned to the servo module. This data is processed by the

servo module to maintain velocity and position control, according to

module, AMP, and part program constraints.

4C.0

Section Overview

4C.1

How the Digital Servo Card

Works