Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 752

Section 15A

Troubleshooting The Control

15A-42

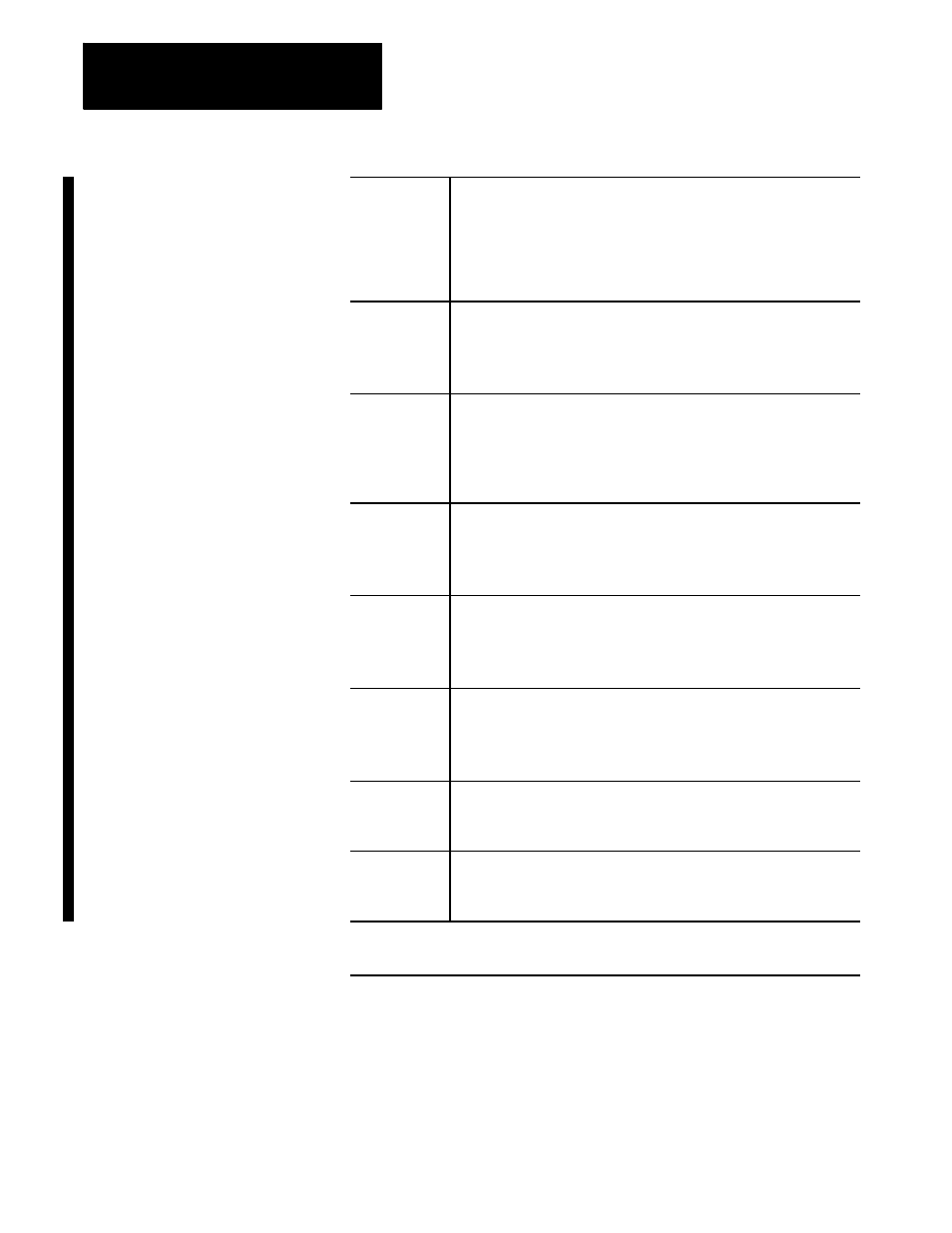

TEMPERATURE

1

System Module Over Temperature

The 1394 contains a thermal sensor which senses the internal ambient

temperature. Causes could be that : The cabinet ambient temperature is

above the 70 deg C rating. The machine duty cycle requires an RMS current

exceeding the continuous rating of the controller. The airflow access to the

1394 is limited or blocked. An axis module or a system module FAN has

failed.

PHASE LOSS

system Module Phase Loss (0)

The 1394 system module has detected a loss of one of the input power

phases. The three--phase input line is monitored and a fault will be issued

when a phase loss is detected. Typical causes include, one, two or all three

of the input line fuses have opened, contactor malfunction, or incorrect wiring.

GROUND

FAULT

System Module Ground Fault (0)

The 1394 system module has detected a ground fault. The system

generates a ground fault when there is an imbalance in the DC bus of greater

than 50 A. This drive error can be caused by incorrect wiring (verify motor

and ground wiring), motor malfunction, or an axis module IGBT malfunction,

or a short to ground

SHUNT

TIMEOUT

**

System Module Shunt timeout (0)

The shunt resistor has timed out due to an amount of regeneration energy

produced by the motor exceeding the limit of the shunt resistor by more than

5%. You may require a properly sized shunt, modification of the duty cycle

of the application, or the addition of an external shunt for additional capacity.

OVER

CURRENT

**

System Module Current Limit (0)

The system module has reached the limit of its current capabilities. The total

motoring and regeneration current produced has exceeded the current

capability of the system module by 5% or more. You may need to reduce the

acc /dec profiles or increase the size of the system module.

PRE CHARGE

**

System Module Pre- Charge (0)

The DC bus voltage did not rise to operating levels (285 V) within .5 sec after

3 phase power was applied to the system. This can occur if : a short is

detected on the DC bus . An axis is enabled before the pre--charge check is

complete, or if torque is commanded before full bus voltage is present.

SHUNT UTIL

**

value

Shunt resistor utilization percentage. This is a display of the amount of heat

(current) that the shunt resistor has absorbed. A value approaching 100%

indicates that the shunt resistor is saturated and will not be able to sustain

further dynamic use.

REGEN UTIL

**

value

Regeneration unit utilization percentage. This is a display of the amount of

heat (current) dissipation that the regeneration electronics have absorbed. A

value approaching 100% indicates that the regen electronics are becoming

saturated and will not be able to sustain further dynamic use.

1 Over Temperature Indicators are for the system module and axis modules only. They do not

reflect any motor over temperatures that may occur. Motor thermal switches (if available) should

be wired into the E-STOP string.