4b.2.3 servo module battery replacement – Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 161

Section 4B

Connecting the 3-axis Servo Module

4B-15

Important: Battery backup is required for absolute encoders only.

Incremental encoders do not require battery backup.

The servo module provides battery backup for the absolute encoder

position register. This register retains position data during power loss.

The battery backup power originates from the batteries plugged into the

servo board at connector CN10.

Even if battery backup fails, or the encoder cable is temporarily

disconnected, the encoder will still maintain position data for up to 24

hours. This also allows for battery replacement without loss of data.

The battery backup is tested at power up, and at four hour intervals while

system power is on. If battery voltage drops to 2.8V during the battery

test, the control automatically displays the warning message “REPLACE

ABSOLUTE FEEDBACK BATTERY” on the operator panel.

Important: Once the “REPLACE ABSOLUTE FEEDBACK BATTERY”

message is displayed, it is essential that the batteries be replaced to avoid

loss of absolute position data.

To replace the servo module battery, turn all system power OFF and

disconnect the old batteries from CN10 on the servo module. Battery

replacement instructions are included with the battery replacement kit.

Before installing new batteries, use a voltage meter to make sure that new

battery voltage is higher than 3.5V dc.

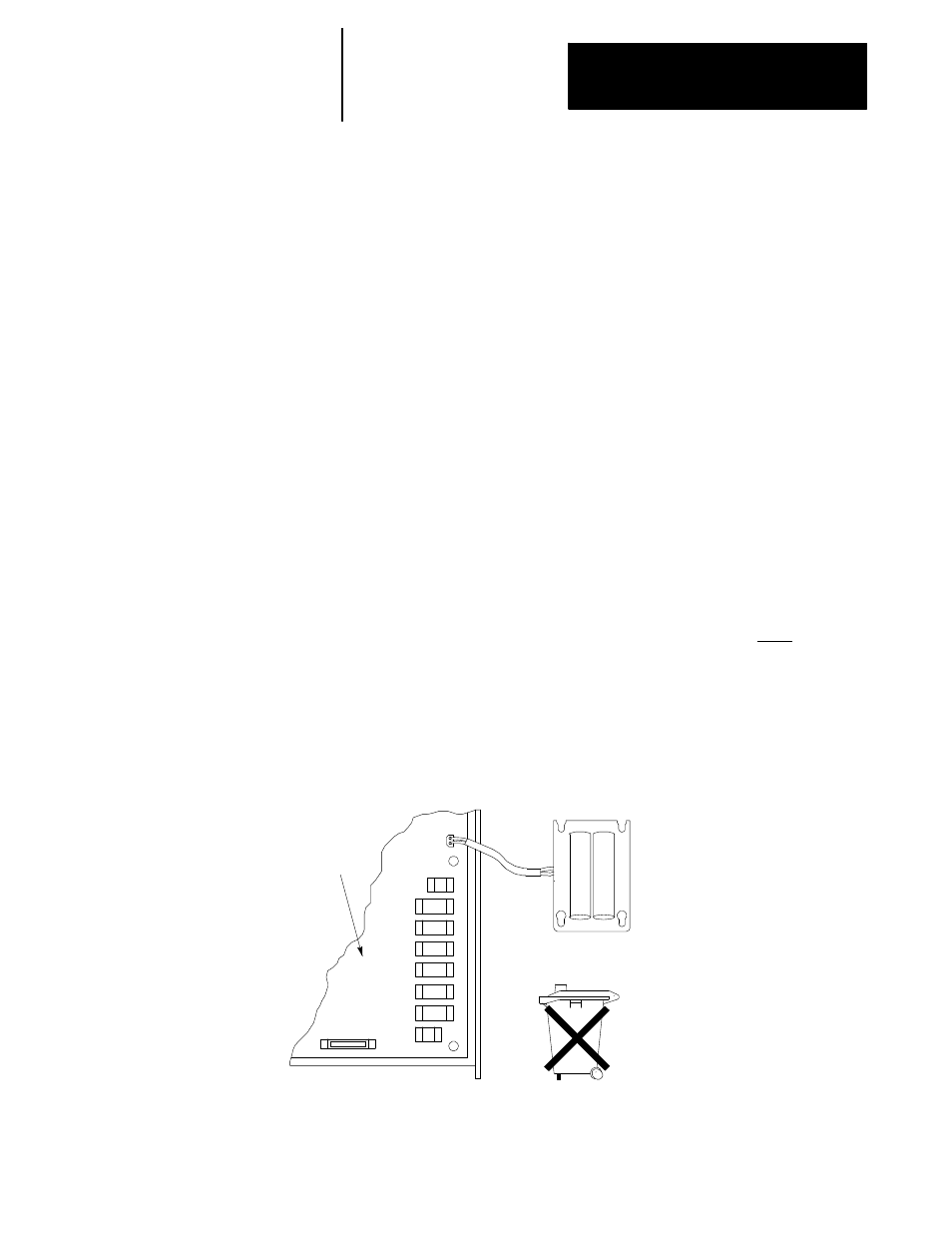

Figure 4B.13

Digital Servo Module Battery Connector CN10

Servo Module

CN10

CN8

CN2

CN3

CN4

CN5

CN6

CN7

CN9

CN12

The lithium battery contains heavy metals and

must be collected separately from other waste.

4B.2.3

Servo Module Battery

Replacement