Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 663

Section 13A

Connecting 8520 Digital Drive Systems

13A-29

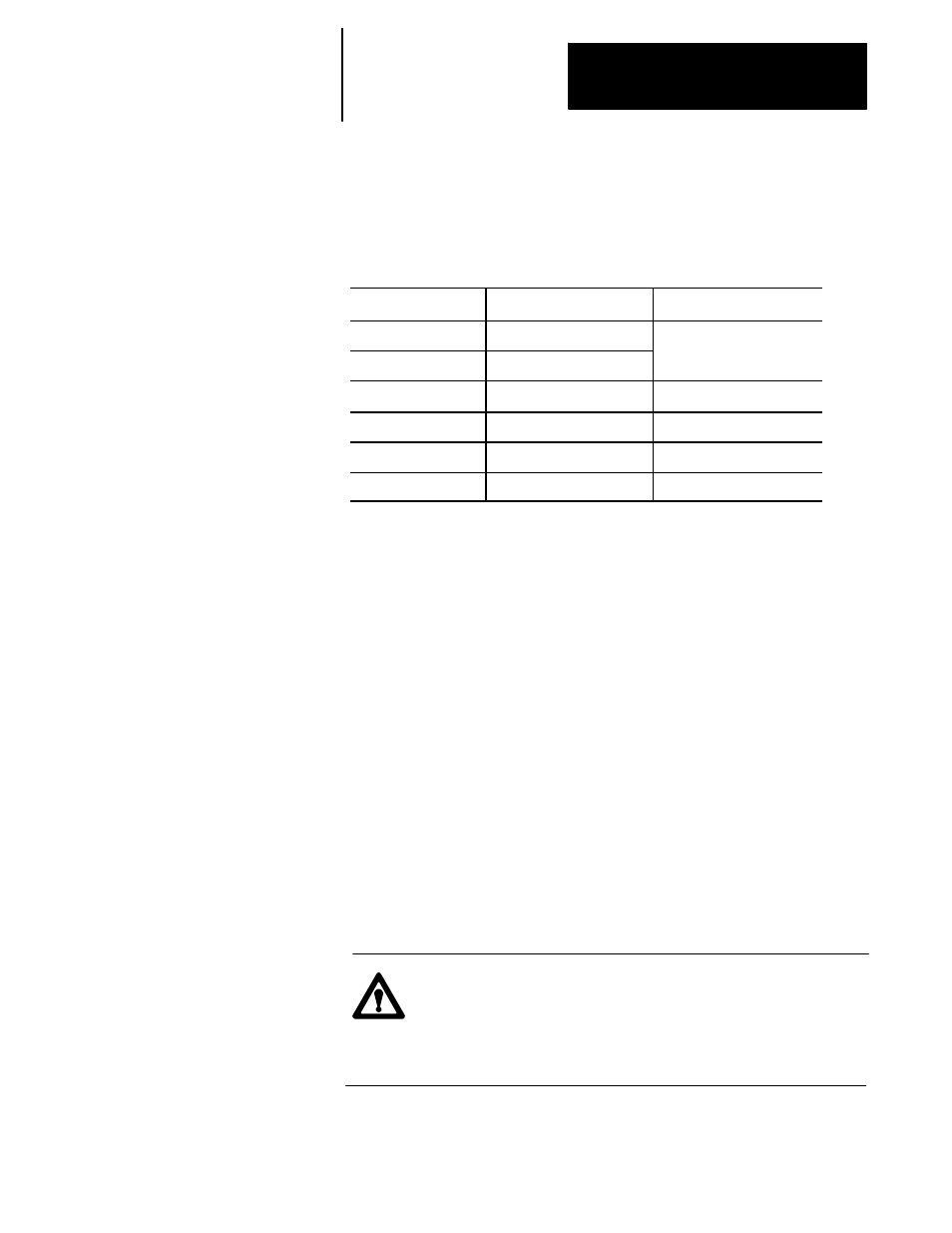

Table 13A.Q lists the servo encoder specifications.

Table 13A.Q

Servo Encoder Specifications

Absolute Encoder

Incremental Encoder

Number of Pulse

8192 pulse/rev

6000 pulse/rev

Number of Multi-turning

±

99999 turns

Resolution

8192

´

4 = 32768 counts/rev

6000

´

4 = 24000 counts/rev

Supply Voltage

+5V (+10%, -1%)

+5V (+10%, -1%)

Battery Backup Voltage

2.9V to 4.5V

N/A

Weight

500 g

500 g

Incremental Encoders

Incremental encoders provide coarse axis position feedback to the servo

module. These encoders also provide U, V, and W motor phase signals for

use in motor commutation until the first marker is detected. After the first

marker is detected, the servo module determines incremental axis position

from the A, B, and C signals which are output by the encoder.

After initial power-up, the control must determine motor phasing by

finding the encoder marker. Until this marker is found, phasing is

estimated using the U, V, and W phase signals. This limits motor power to

approximately 85% of maximum.

After the first marker is detected, the exact electrical position is known.

Since precise commutation is now possible, full power is possible.

An axis homing cycle is required to establish axis position after the motor

is phased. Once axis position is established, axis position feedback is

transmitted back to the servo module in an A quad B format with marker.

This feedback transmission takes place on an incremental basis.

ATTENTION: Do not adjust encoder alignment. Commutation

requires the encoder marker to be aligned with the windings of

the servo motor. This alignment process is done during the

mounting of the incremental or absolute encoder to the servo

motor.