Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 340

Section 6

Emergency STOP Design

6-4

Important: You may need to add a pilot relay if your E-Stop has one of

these characteristics:

the E-Stop string is very long

devices on the string cause a such a large line drop in the string that the

E-Stop relay will not latch.

In these cases, the control may:

not come out of E-Stop

enter E-Stop at different times during operation when the E-Stop string

voltage varies slightly

If your application requires a separate E-Stop pilot relay, you must provide

an external power supply to power the E-Stop string. The contactors of this

pilot relay are used to break the controls 12V E-Stop string. A typical

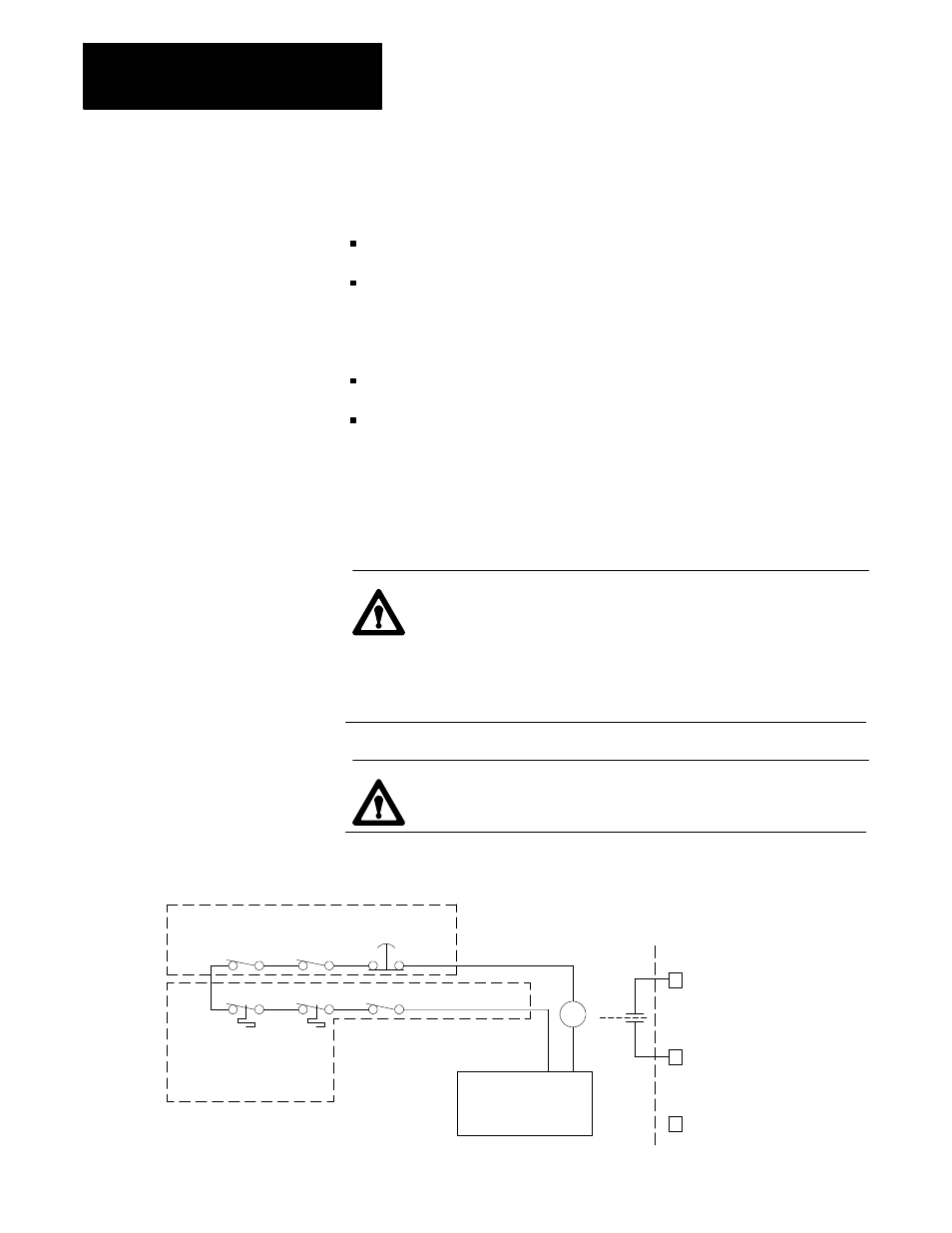

layout for this E-Stop string is shown in Figure 6.3.

ATTENTION: E-Stop wiring with a pilot relay requires circuit

continuity for normal operation (a customer’s E-Stop string

should be a normally closed circuit). Loss of power to the

external power supply should constitute an E-Stop condition.

Failing to do this may cause injury to personnel or damage to

the machine tool.

ATTENTION: Contact ratings on the control are DC only.

Figure 6.3

Typical Customer E-Stop String with Pilot Relay

MACHINE

DRIVES ENCLOSURE

Motor thermal switches

may be connected

directly

Extreme overtravel

switches

Drive System Ready,

(DROK TB1 on 1394)

(internally Connected on 9/440)

Remote

E-Stop

button

4

5

Customer Supplied

External Power Supply

for E-Stop String

6

Pilot Relay

11250-I

E-Stop connector (TB1)

on Motherboard for 9/260 or 9/290 and on the

processor board for the 9/230

CR