3a.6.1 wiring an incremental feedback device – Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 104

Section 3A

Primary 9/230 Components

3A-21

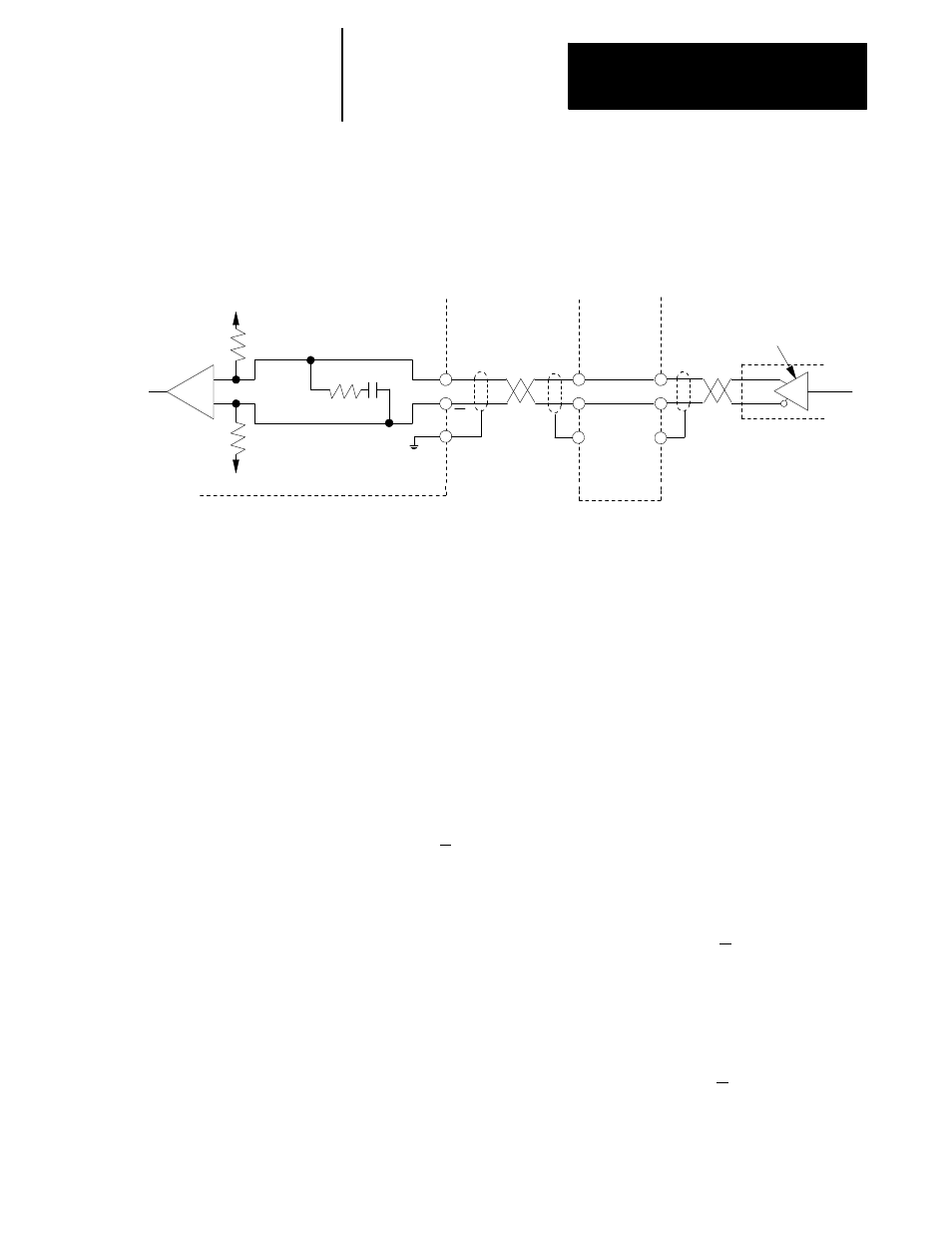

Figure 3A.13 shows an incremental feedback device equivalent circuit for

feedback channel A.

Figure 3A.13

Incremental Feedback Device Equivalent Circuit

Differential

Line Driver

Customer

Encoder

+5V

+5V

768

W

768

W

221

W

0.01u f

A

A

Ch A HI

Ch A LO

Termination Panel

+

--

Processor Module

8500-TPC

Cable

11306-I

Wiring Position Feedback

Feedback devices used with the control must be configurable such that the

marker Z is true at the same time that channels A & B are true. If you are

using an Allen-Bradley 845H encoder this requirement will already be met

if you wire them as shown in the cable diagrams on page 7A-1.

If you are using an encoder type feedback device other than the

Allen-Bradley 845H encoder, then use the following wiring procedure:

1.

Obtain the encoder output timing diagram from the vendor’s data

sheets. A typical one is provided in Figure 3A.14 as an example.

2.

On the timing diagram, look at the marker Z and its complement,

marker Z. Whichever one is low for most of the encoder revolution

and pulses high should be wired to “CH Z.HI” of the encoder

termination panel. Wire the remaining marker to “CH Z.LO” of the

encoder termination panel.

3.

Look at channel B and its complement, channel B. Whichever one is

high for at least part of the marker interval should be wired to

“CH B.HI” of the encoder termination panel. It is possible that both

channels meet this requirement depending on the encoder

manufacturer, in which case, use either one. Wire the remaining

channel to “CH B.LO” of the encoder termination panel.

4.

Look at channel A and its complement channel A and repeat as in

step 3 using “CH A.HI” and “CH A.LO” of the encoder termination

panel.

3A.6.1

Wiring an Incremental

Feedback Device