Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 855

Error and System Messages

Section 16

16-35

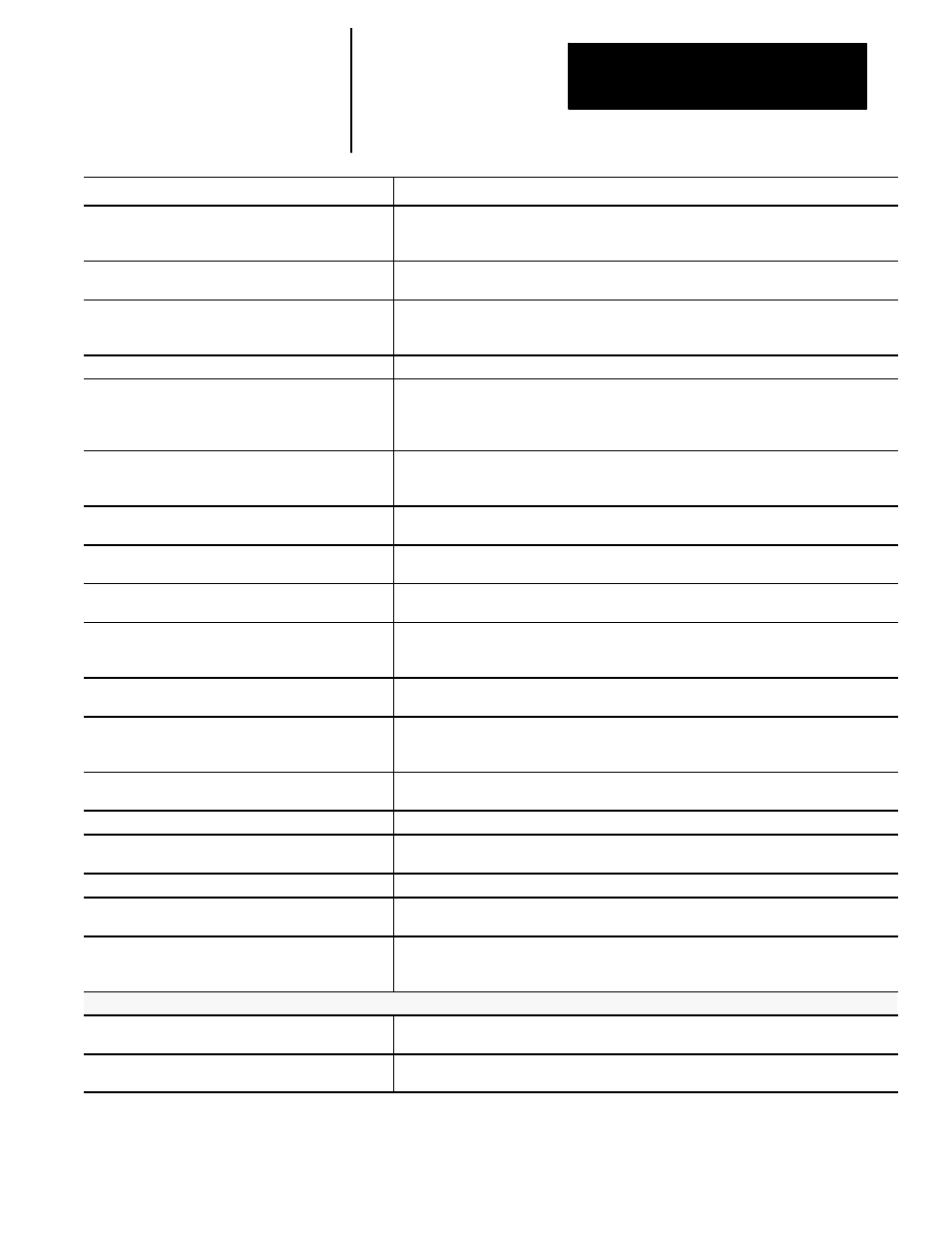

Message

Description

PROGRAM ACTIVE

An attempt has been made to delete or perform some other operation to a program that was

activated for automatic execution. The program must be deactivated using the {CANCEL

PRGRAM} softkey.

PROGRAM ACTIVE IN ANOTHER PROCESS

This dual lathe error appears when one process attempts to open a file for edit, deletion, etc.,

while that file is active in another process.

PROGRAM BEING EDITED

An attempt has been made to copy, verify, or perform some other operation on a program that is

still in the edit mode. It is necessary to press the {EXIT EDITOR} softkey from the edit menu to

properly end an editing operation.

PROGRAM BLOCK TOO LONG

More than 128 characters were entered into a single block.

PROGRAM CURRENTLY IN USE

A subprogram or paramacro program was called that is currently being used to perform some

other operation (such as editing or copying). Typically, this message is the result of attempting

to edit a program that was not properly closed. A program remains in the edit mode until the

{EXIT EDITOR} softkey is pressed from the program edit menu.

PROGRAM NAME TOO LONG

An attempt was made to create a program with a program name longer than 8 alphanumeric

characters. If a large, descriptive program name is desired, a comment may be added to the

right of the program name using the {PRGRAM COMENT} feature.

PROGRAM NOT FOUND

The program cannot be located in memory. Check to make sure the program name was

correctly entered.

PROGRAM OPEN FOR EDIT IN ANOTHER PROCESS

On a dual-processing system, you cannot edit a program that is active in another process. You

will need to switch processes if you want to edit the other program.

PROGRAM REWIND ERROR

An attempt to rewind the tape was not successful. Check to be sure that the tape reader is

functioning properly and the tape is on the drive sprockets.

PROGRAM SHOULD START HERE

When performing a {MID ST PRGRAM} operation to restart a program, the control has found the

block that the program execution should begin at, and selected that block as the next block to

be executed. That block is the block immediately following the one containing an @.

PROGRAMMED AXIS IS OFF OR DETACHED

Part program blocks are attempting to program motions on an axis that has its servos either off

or configured as detached in AMP.

PROGRAMMED G26 DEPTH < TRIGGER TOLERANCE

A G26 block is programmed with an integrand less than or equal to the AMPed Adaptive Depth

Trigger Tolerance amount. A block decode error is given and the block will not execute until the

integrand in the block is made larger or AMP is modified to reduce the trigger tolerance.

PROGRAMMED SPINDLE UNAVAILABLE

The programmer attempted to program the follower spindle independently (M03, M04, M05, or

M19) while spindle synchronization was active.

PROGRAMS ARE DIFFERENT

A program verify operation has determined that the two selected programs are not identical.

PROGRAMS ARE IDENTICAL

A program verify operation has determined that the two selected programs are identical

matches.

PROGRMABLE ZONE 2 VIOLATION

An attempt was made to move the indicated axis into the area defined by programmable zone 2.

PROGRMABLE ZONE 3 VIOLATION

An attempt was made to move the indicated axis into (or out of) the area defined by

programmable zone 3.

PROGRMD G26 DEPTH < TRIGGER TOLERANCE

The programmed adaptive depth deflection (hole depth) is less than the probe tolerance value.

You must either increase the programmed block depth, or decrease the AMPed probe tolerance

value.

Q

QPP ANGLE WORD SAME AS AXIS NAME

AMP has downloaded an angle word for QuickPath Plus that is the same as an axis name.

AMP must be reconfigured; the angle word cannot be the same as an axis name.

QPP BLOCK FORMAT ERROR

Data is incorrectly entered or insufficient data is entered for the control to correctly execute a

QuickPath Plus block or pair of QuickPath Plus blocks.