9a.2.5 flat panel horizontal adjustment – Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 478

Section 9A

Operator Interface

9A-11

Set the node address by cutting the wire jumper(s) according to Table 9A.E

shown below.

Table 9A.E

Operator and Removable Operator Panel Node Address Setting

Node Address

Jumper

Hexidecimal

Binary

JP1

JP2

00

00

Short

Short

01

01

Open

Short

02

10

Short

Open

03

11

Open

Open

The node address may be any number between 00 and 03. You may have a

total of 4 interface assemblies on the I/O ring (if the removable operator

panel interface is used a separate power supply is required if you use more

than 2 assemblies). The same node address can be used for different types

of modules, but may not be used more than once for a specific type of

module.

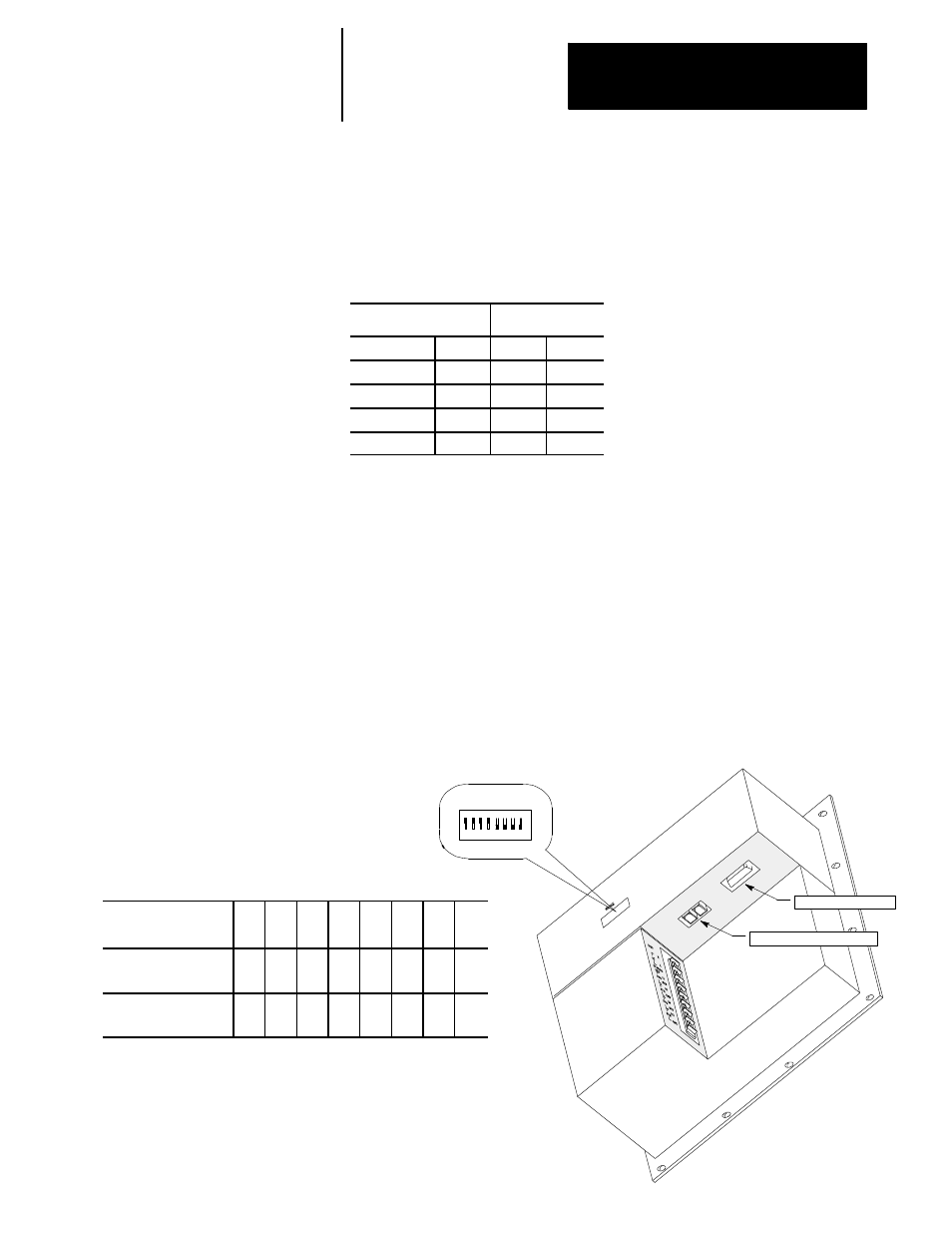

The flat screen operator panel has a set of dip switches used to adjust the

screens horizontal centering. Screen centering on the flat panel must be

adjusted for different connecting control types. Figure 9A.8 illustrates the

location and use of these dip switches.

Figure 9A.8

Flat Operator Panel Horizontal Adjustment Dip Switches

For this control type: Sw

1

Sw

2

SW

3

SW

4

SW

5

SW

6

SW

7

SW

8

9/230, 9/260, and

9/290 CNCs

On Off On Off Off Off Off Off

9/440 CNCs

(factory default)

On On On On Off Off Off Off

9A.2.5 Flat Panel Horizontal

Adjustment

Fiber Optic Connection

Video Connection

1

23

4

56

ON

7

8

HOR PHASE