Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 307

Maximum Encoder Channel Frequency =

Clock

360

x 1.15

90-Eq

Section 5B

9/440HR CNC/Drive System

5B-17

analog servo feedback -- If you are using one of the two analog ports to

control an axis these high--resolution feedback device ports can be used

for its position feedback.

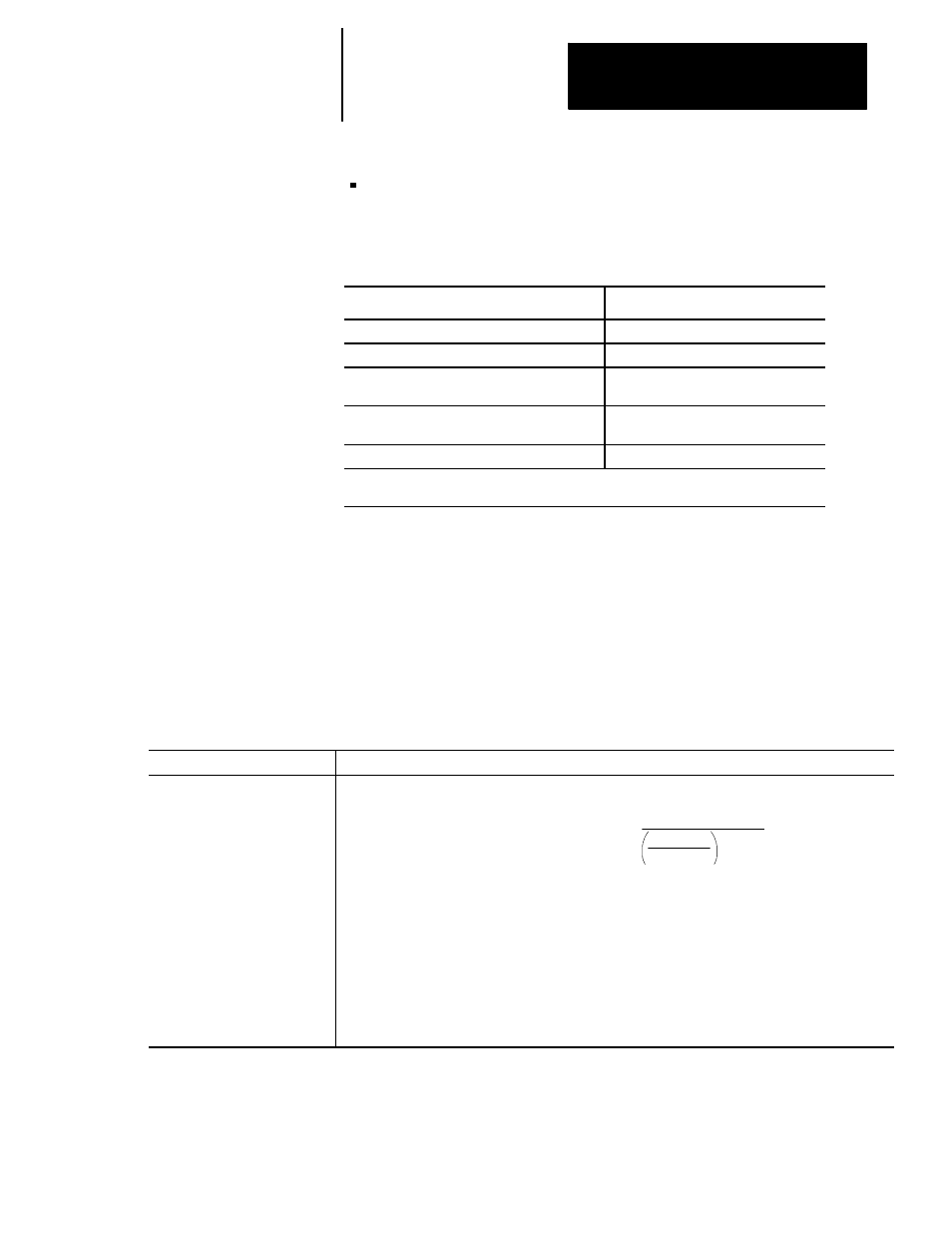

The 9/440HR supports:

Feedback Device

Additional hardware

Allen-Bradley 845H Series Differential Encoders

----

Sony Magnascale Model GF-45E

Board-type detector model MD10-FR

Heidenhain Model 704

External interpolation and digitizing

model EXE602 D/5-F

Futaba Pulscale Model FM45NY

PCB interface Module model CZ0180

with cable PCB020EA

Heidenhain Distance--coded Marker

LS176

1

1

Refer to your vendor’s catalog for a complete listing of additional hardware you may need

to support distance--coded markers.

Other feedback devices can be compatible if they comply with the

specifications listed in Table 5B.A. Refer to the 9/Series CNC AMP

Reference Manual, publication 8520-6.4, for more information.

The following table lists feedback specifications for a differential encoder

however, this information can be interpreted to select an appropriate linear

scale.

Table 5B.A

Encoder Specifications

Item

Specification

Maximum Encoder Channel

Frequency (ECF)

Use the following equation to determine the maximum channel frequency

Where:

Clock -- is the Control’s Feedback Clock Frequency:

5 x 10

6

-- for 9/230, 9/440, and three--axis servo cards.

2.3 x 10

7

-- for 9/260 or 9/290 systems using a four--axis servo card

E

Q

= Quadrature Error in Degrees

1.15 = Our minimum recommended safety factor

As long as the actual feedback channel frequency does not exceed the maximum channel frequency

calculated above, the servo module should process the feedback data without a quadrature fault.