Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 408

Section 7A

Connecting Components

7A-60

Table 7A.A

Cable and Connector List (continued)

Cable No.

Control

From Module and Connector

Cable Name

To Module and Connector

Cat. No.

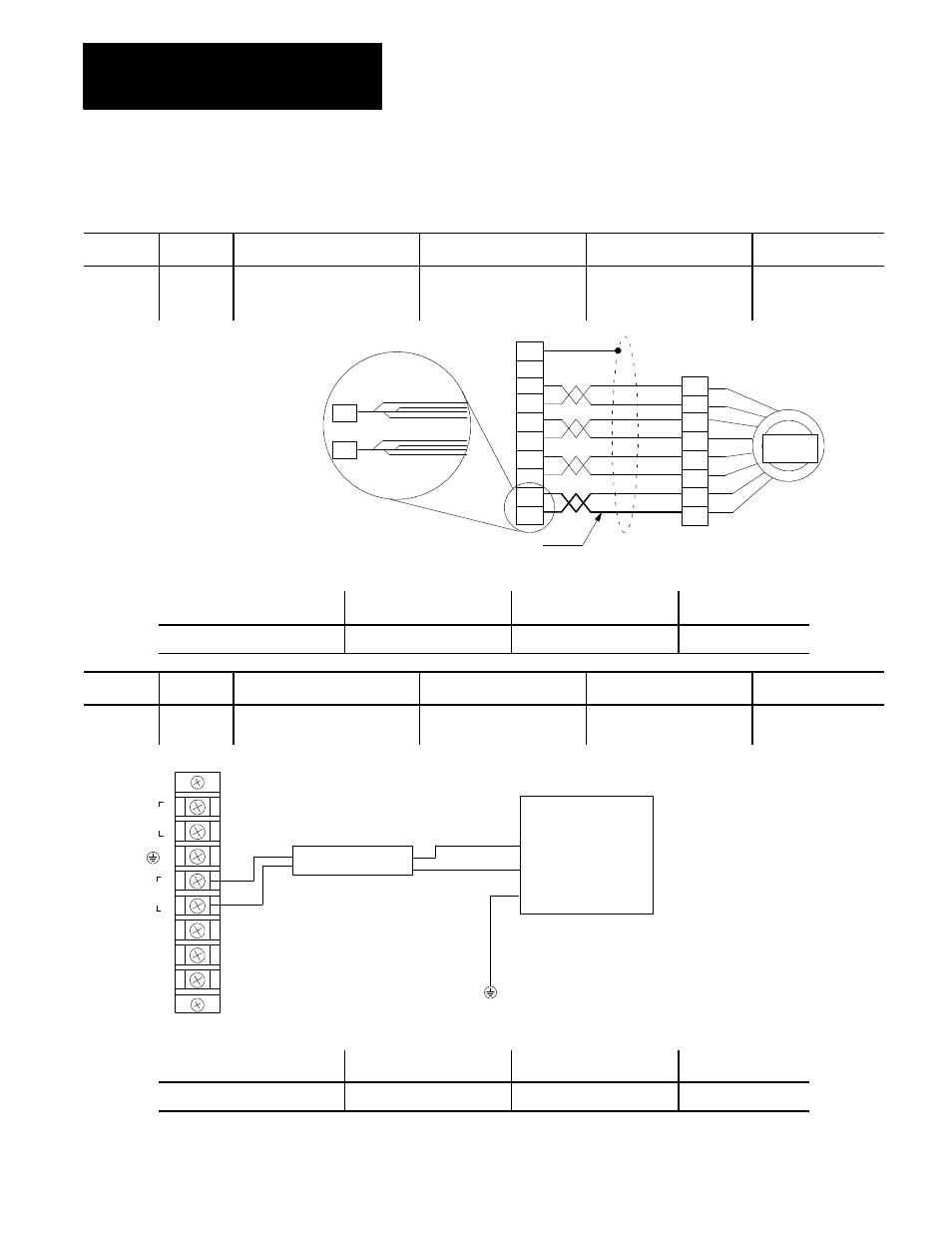

C52

9/440

Resolver--

based

9/440 Resolver--based System

Module Feedback Board

Encoder Signal Cable

AB 845H Encoder

Customer Supplied

16 AWG for encoder power

pins 6 and 12 (use four 22 gauge)

12

6

Use four 22 gauge twisted pair to make the

power connections to pins 6 and 12. Strip 1 inch

of one lead and solder into pin. Solder the three

remaining leads to the exposed one inch of wire

to make the equivalent of 16 gauge wire. Use

the appropriate wire tape. Repeat for both pins.

A

H

I

B

C

J

AB 845H

Encoder

1

7

8

3

9

5

11

12

D

F

6

2

Connector On End of Cable

Cable Type

Connector On End of Cable

Max. Cable Length

AMP 770581--1

Belden 8307

MS Type

25 m (82 ft.)

Cable No.

Control

From Module and Connector

Cable Name

To Module and Connector

Cat. No.

C53

9/440 (all)

On/Off Power Control Module

115V Transformer Feed

24V Logic Transformer

(customer supplied)

Prepared by Customer

To local cabinet

PE bus

L1

ac

IN

L2

PE

L1

L2

COMMON

AUX

ac

On/Off Power Control Module

ON SW

OFF SW

High

Low

Customer supplied

24V logic transformer

Important: Make sure 24V logic power is applied

before allowing 3--phase power to come up. Logic

power must be applied to the system module first.

C53

Connector On End of Cable

Cable Type

Connector On End of Cable

Max. Cable Length

Miscellaneous

Belden 9409

Miscellaneous

Line Drop Limitation