Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 192

Section 4B

Connecting the 3-axis Servo Module

4B-46

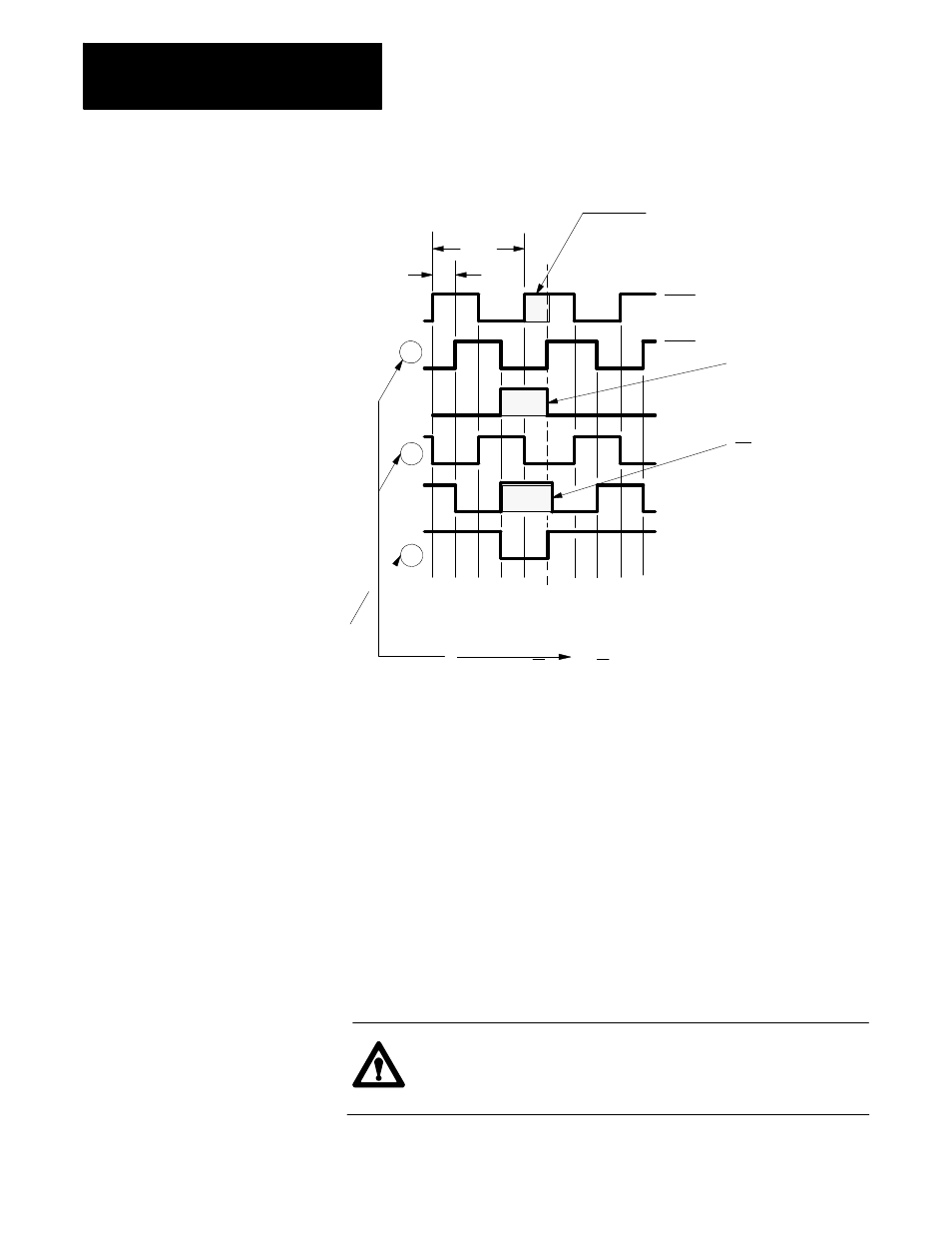

Figure 4B.37

Example of a Typical Vendor Encoder Timing Diagram

1 cycle

Hi

Lo

Channel A

B

A’

B’

Z’

Z

Optional

STEP 3

C h a n n e l A is h ig h a t

le a s t p a rt o f m a r k e r

in te r v a l. C o n n e c t

o

t

“C H A . H I” o f

te rm in a tio n p a n e l.

STEP 1

H ig h m a rk e r

in te rv a l. C o n n e c t to

“C H Z . H I” o f

te rm in a tio n p a n e l.

STEP 2

B is h ig h fo r a t

le a s t p a r t o f m a r k e r

in te r v a l. C o n n e c t t o

“C H B . H I” o f

te r m in a tio n p a n e l.

CCW rotation

viewing shaft

W ire C H B , C H A , a n d C H Z to C H B L O ,

C H A L O a n d C H Z L O , re s p e c tiv e ly ,

o n th e te rm in a tio n p a n e l.

Be l o w w ir in g is a n e x a m p le o n ly o f

a ty p ic a l v e n d o rs e n c o d e r . S e e y o u r e n c o d e r

v e n d or s tim in g d ia g r a m .

N O T E :

11307-I

90°

,

2.

On the timing diagram, look at the marker Z and its complement,

marker Z’. Whichever one is low for most of the encoder revolution

and pulses high should be wired to “CH Z.HI” of the encoder

termination panel. Wire the remaining marker to “CH Z.LO” of the

encoder termination panel.

3.

Look at channel B and its complement, channel B’. Whichever one is

high for at least part of the marker interval should be wired to

“CH B.HI” of the encoder termination panel. It is possible that both

channels meet this requirement depending on the encoder

manufacturer, in which case, use either one. Wire the remaining

channel to “CH B.LO” of the encoder termination panel.

4.

Look at channel A and its complement channel A’and repeat as in step

3 using “CH A.HI” and “CH A.LO” of the encoder termination panel .

ATTENTION: You can find a marker even if your encoder is

not phased properly. An improperly phased encoder will still

home successfully.