Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 834

Error and System Messages

Section 16

16-14

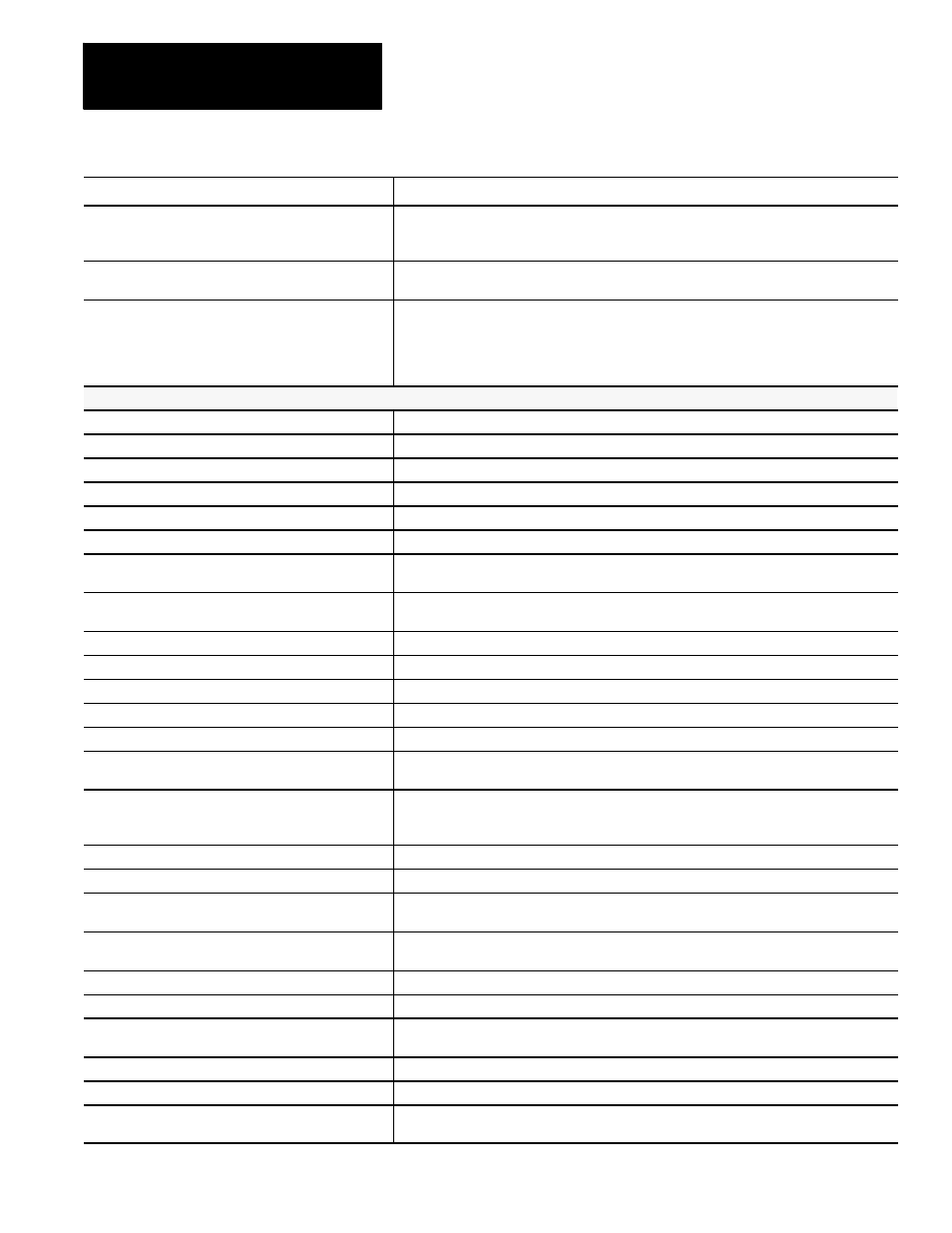

Message

Description

EXTRA DATA IN QPP BLOCK

The QuickPath Plus block has been programmed with too many parameters. For example, you

cannot program a G13 block with both axis data and an angle word or with an L or A word in the

block.

EXTRA I/O RING DEVICE

An I/O device that has not been defined in the I/O assignment file is physically present on the

I/O ring.

EXTRA KEYBOARD OR HPG ON I/O RING

The control detected a keyboard or HPG on the 9/Series fiber optic ring that was not configured

as a ring device. The I/O ring will still function and the control will NOT be held in E-Stop. You

may also use the keyboard or HPG by selecting it as the active device via the corresponding

PAL flags. You should configure the keyboard or HPG with the I/O assigner utility (See your

9/Series PAL reference manual for details).

F

FCM DUALPORT RAM FAILURE

The FCM detected an error in dualport RAM.

FCM FLASH RAM FAILURE

The FCM detected an error in flash RAM.

FCM LOCAL RAM FAILURE

The FCM detected an error in local RAM at power-up or during the runtime diagnostics.

FCM PLUG CONFIGURE FAILED

The FCM card failed to configure correctly.

FCM PLUG FAULT

The plug on the FCM detected an error.

FCM PLUG NEGOTIATE FAILED

The FCM firmware could not communicate with the plug.

FCM POWER UP SEQUENCE FAILURE

Power-up failed. Try again. If error appears again, contact your Allen-Bradley sales

representative.

FCM REVISION CHECK FAILURE

Revision on module is out-of-date. Contact Allen-Bradley sales representative to get latest

revision of the module’s firmware.

FCM ROM FAILURE

The FCM detected an error in ROM during runtime diagnostics.

FCM SHADOW RAM FAILURE

The FCM detected an error in shadow RAM.

FCM SPURIOUS INTERRUPT

A spurious interrupt occurred on the FCM card.

FCM VRTX ERROR

A call from VRTX from the FCM card firmware returned an error.

FCM WATCHDOG

The watchdog on the FCM card timed out.

FDBK NOT AVAILABLE ON 4TH AXIS OF BOARD

An attempt was made to receive feedback from the axis that is configured as the fourth axis on a

servo board. You can only receive feedback from the first three axes on a servo board.

FEEDBACK DISCONNECTED

The control has detected a loss of feedback from the encoder. The most likely cause of this

error would be a broken or disconnected wire. Axis homing will be required after the error

condition is corrected.

FEEDBACK OPTION NOT INSTALLED

A PTO check determines the legal number of axes.

FEED AXIS DATA NOT PROGRAMMED

Feed axis data required during a grinder fixed cycle was not programmed.

FEED AXIS MOTION NOT ALLOWED

During Virtual C programming, no axis motion is allowed on the axis specified as the feed axis in

AMP.

FEED TO HARDSTOP PROGRAMMING ERROR

No axis, or more than one axis, was programmed in a G24 block. Or the programmed axis

integrand was not programmed in the block.

FILE CANNOT BE CONVERTED TO EIA FORMAT

The file requested to be output to a device has characters that cannot be converted to EIA.

FILE DOWNLOAD COMPLETE

Status message that means the download has completed.

FILE DOWNLOAD ERROR

Check file download and file download configuration screens to make sure all fields are entered

correctly.

FILE DOWNLOAD IN PROGRESS

This status message means a file is being downloaded.

FIXED CYCLE ALREADY ACTIVE

You cannot program a fixed cycle with a fixed cycle already active.

FIXED CYCLE PROGRAMMING ERROR

A fixed cycle has been programmed incorrectly. Verify that the correct parameters have been

used and that parameters restricted to integer or positive values are programmed as such.