Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 306

1

3

5

7

9

11

13

15

2

4

6

8

10

12

14

16

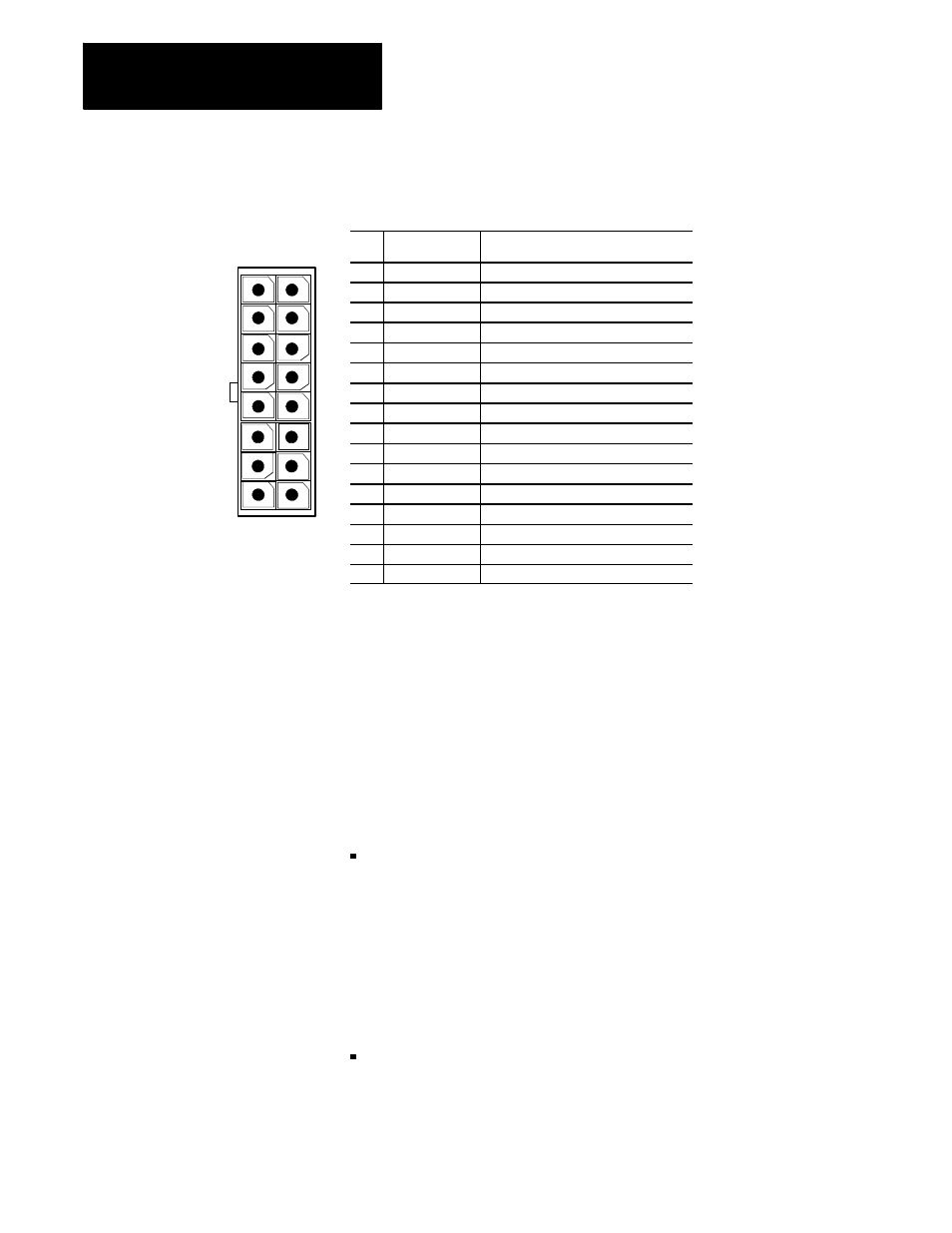

View of connectors

on 9/440 board.

Center

Tab

Section 5B

9/440HR CNC/Drive System

5B-16

Figure 5B.7

Pin Configuration for the Encoder Connectors on the 9/440HR CNC/Drive

Pin

Signal

Description

1

Shield

PE

2

GND

Encoder Supply Ground

3

+5V PWR

+5V Encoder Power Supply

4

Shield

No connection

5

CHZ_LO

Feedback device Channel Z

6

CHZ_HI

Feedback device Channel Z

7

Shield

No connection

8

CHB_LO

Feedback device Channel B

9

CHB_HI

Feedback device Channel B

10

Shield

No connection

11

CHA_LO

Feedback device Channel A

12

CHA_HI

Feedback device Channel A

13

N/C

No connection

14

N/C

No connection

15

+SENSE

Encoder Sense Power

16

--SENSE

Encoder Sense Ground

Important: For proper operation, you must connect pins 15 and 16 to the

supply loading device.

Compatible Optional Feedback Devices and Spindle Feedback

This section discusses optional feedback devices that are compatible with

the 9/440. The 9/440HR supplies these devices with +5V power.

Feedback devices must return a 5V--compatible output signal to the

control.

This feedback device can be used to provide:

auxiliary position feedback -- Digital systems require the

motor--mounted feedback device, provided on our standard digital servo

motors, be used for velocity--loop feedback. This motor--mounted

feedback device can also be used to close the position loop or an

additional auxiliary feedback device, as discussed in this section, can be

used for the position loop. You can not replace or bypass the

motor--mounted feedback device. The motor--mounted feedback device

must be used for velocity feedback and to attain proper motor

commutation on digital servo systems.

spindle feedback -- Provide position feedback for your spindle using

these high--resolution feedback device ports.