Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 105

Section 3A

Primary 9/230 Components

3A-22

If the previous procedure is not performed correctly, inconsistent homing

of the axis may occur. If your encoder phasing cannot provide an interval

at which the marker and both channels are simultaneously true, the encoder

should be considered incompatible with the control.

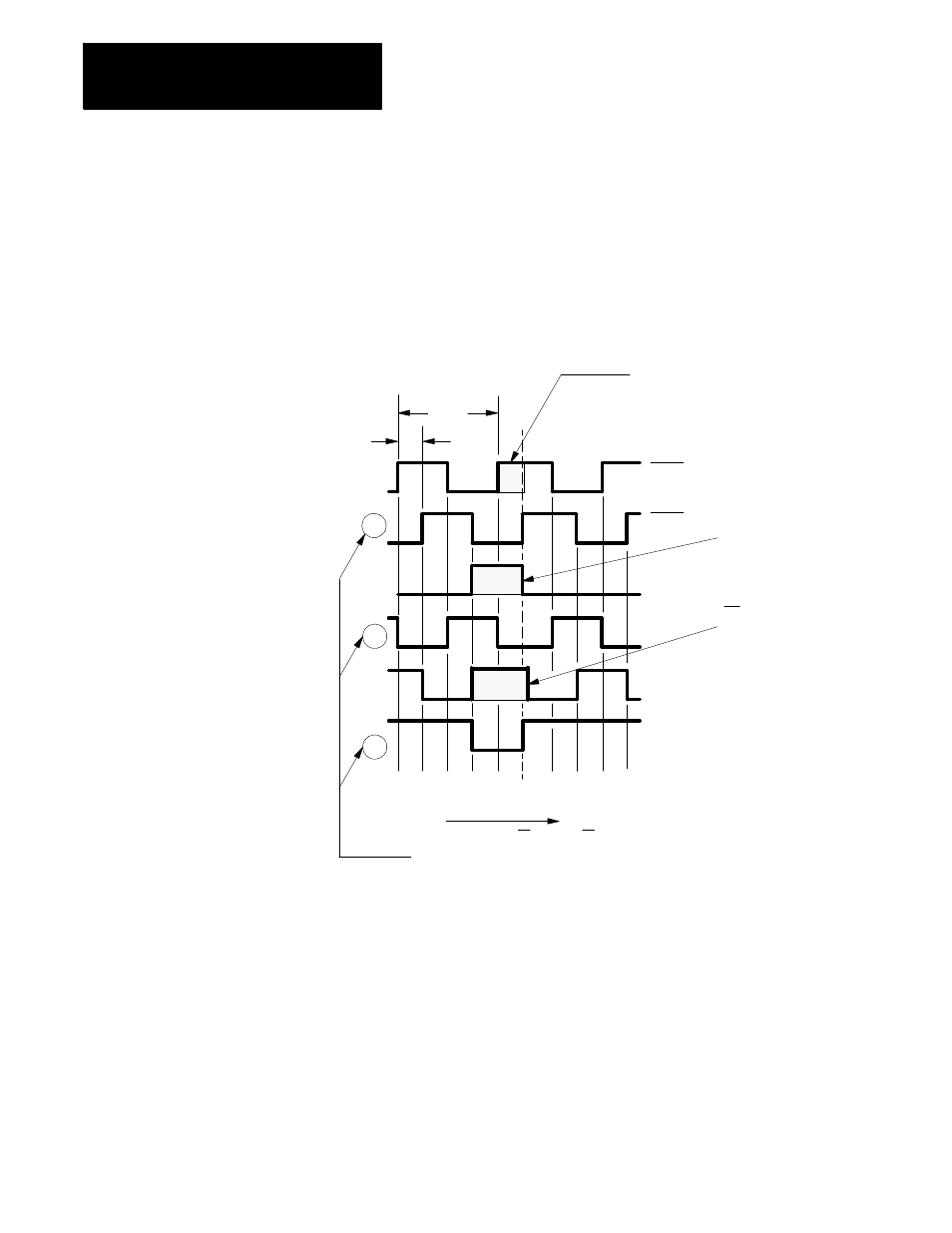

Figure 3A.14

Example of a Typical Vendor Encoder Timing Diagram

1 cycle

Hi

Lo

Channel A

B

A’

B’

Z’

Z

Optional

STEP 3

C h an ne l A is h igh at

le a st pa rt o f m a rker

in terval. C o nn ect o

t

”C H A . H I” of

te rm ina tio n p a ne l.

STEP 1

H ig h m a rker

in terva l. C onne ct to

”C H Z. H I” of

te rm inatio n pane l.

STEP 2

B is h ig h fo r a t

le a st p a rt o f m a rk e r

in te rv a l. C o n n e c t to

”C H B . H I” o f

te rm in a tio n p a n e l.

CCW rotation

viewing shaft

W ire CH B, CH A , and CH Z to CH B LO ,

CH A LO and CH Z LO , respectively,

on the term ination panel.

Below w irin g is an e xa m p le o n ly o f

a typ ica l ve n d ors e n co de r. S e e you r e n co de r

ve nd or s tim in g d ia g ra m .

NOTE:

11307-I

90

°

,

Important: Since positive and negative axis directions can be assigned

without regard to encoder rotation directions, it is possible for the feedback

direction to be ”backwards”. This is easily corrected before attempting to

command axis motion through the AMP parameter Sign of Position

Feedback. Refer to the 9/Series CNC 9/230, 9/260, and 9/290 AMP

Reference Manual, publication 8520-6.4, for more information.