13a.9 feedback devices – Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 662

B

A

C

D

E

F

G

H

I

Section 13A

Connecting 8520 Digital Drive Systems

13A-28

Figure 13A.3 lists the pin assignments for the A series 8500 digital servo

motor connector with brake.

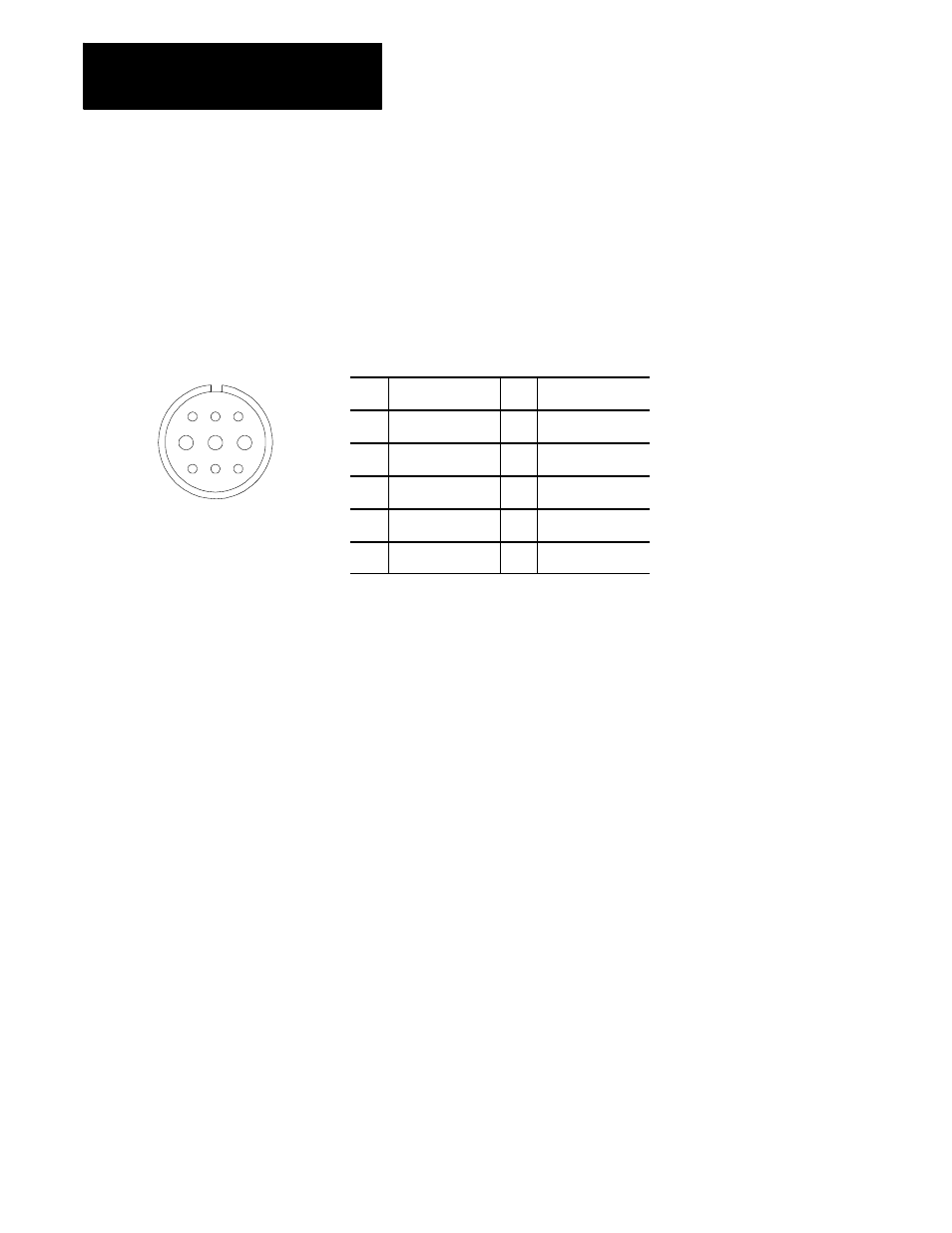

Figure 13A.4 shows the pin layout and pin assignments for the B series

8500 digital servo motor connector with brake.

Figure 13A.4

B Series 8500 Digital Servo Motor Connector and Pin Assignments (with

brake)

Pin

Signal

Pin

Signal

A

Thermal Protector

F

Phase C (W)

B

Thermal Protector

G

Ground and Shield

C

--

H

Brake Terminal

D

Phase A (U)

I

Brake Terminal

E

Phase B (V)

Each servo motor is equipped with a feedback device that is mounted on

the end of the motor that is opposite the shaft end. This feedback device

can be either an absolute or an incremental encoder. The servo module

supplies these encoders with their required +5V power supply.

Each servo motor may also be equipped with a second feedback device for

greater accuracy for positioning feedback. This second feedback device is

normally mounted directly to the moving axis member to avoid

inaccuracies caused by the motor gearing and drive components. When a

second feedback device is used the motor mounted encoder must remain

and is used for velocity feedback as well as motor commutation.

The spindle motor can also be equipped with a feedback device. This

feedback device must be an incremental encoder with A quad B format.

The servo module can supply the spindle encoder with +5V or +15V

power.

13A.9

Feedback Devices