Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 377

Section 7A

Connecting Components

7A-29

Table 7A.A

Cable and Connector List (continued)

Cable No.

Control

From Module and Connector

Cable Name

To Module and Connector

Cat. No.

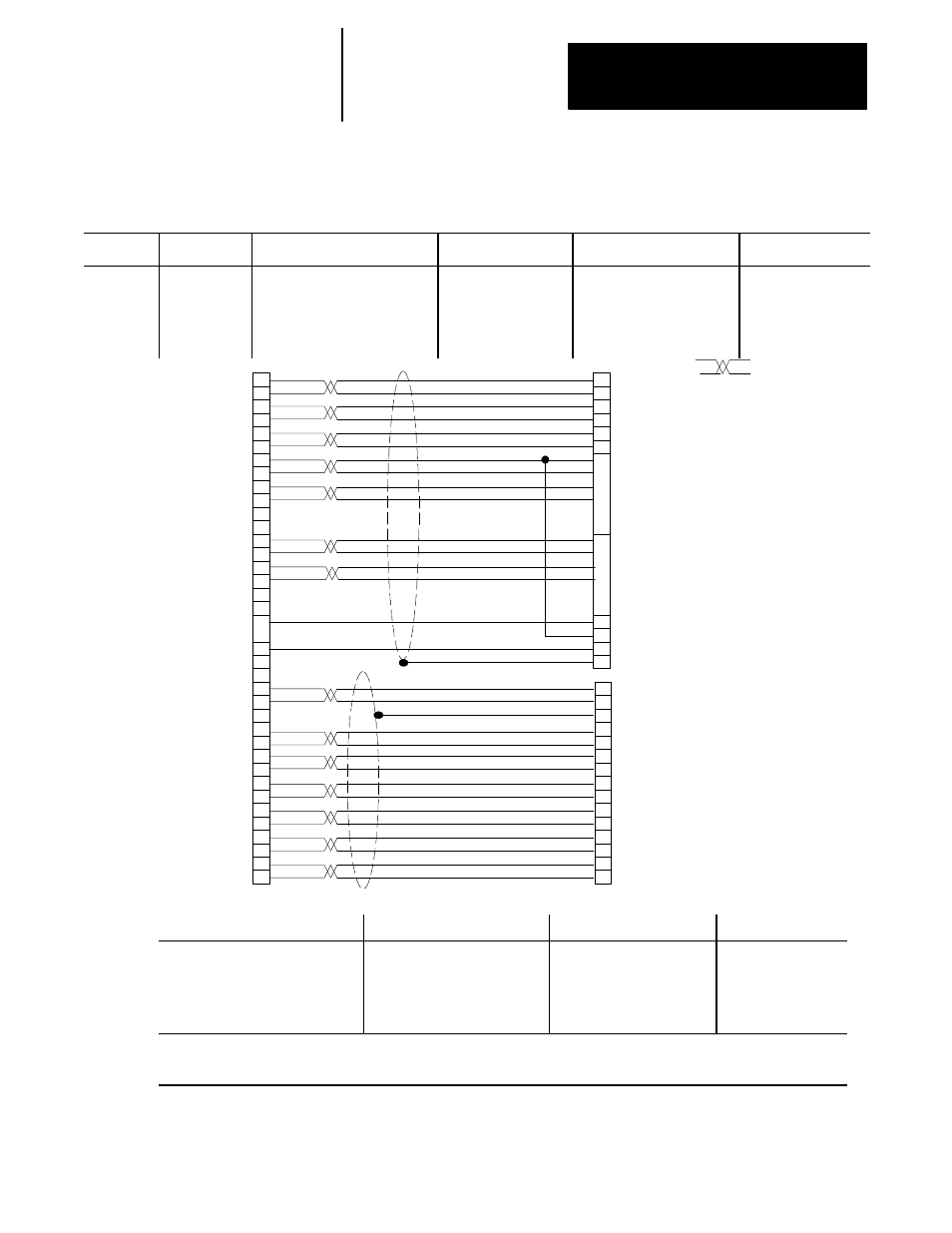

C14

9/230, 9/260,

9/290

8520 Digital

9/230 Processor (8520-DSP only)

servo connectors (J1,J2, or J3) or

4-axis Digital Servo Module

(8520-ENC4) Servo Connector

(J1, J2, J3, or J4)

Drive and Abs. Encoder

Signal Cable

8500 Servo Motor Encoder

and 8520 Digital Servo

Amplifier CNA1-CNA3

Prepared by Customer

Indicates

twisted

pair

With 5V dc

absolute

encoders

Shield wires, no

connection at control end

for either shield wire.

13

43

8

38

35

5

36

6

37

7

14

44

12

42

1

2

3

6

7

10

11

12

13

14

15

17

18

22

23

Absolute

Encoder

Connection

1

Drive Connection

2

44- pin D-shell

A

B

C

D

E

F

G

H

R

11

41

10

40

39

9

15

16

19

28

29

31

20

21

22

24

25

26

34

J

T

23

S

gnd

chb_lo

gnd

gnd

gnd

chz_lo

chb_hi

chz_hi

gnd

/enable

+5v_enc

+5v_enc

+5v_enc

not used

+5v_enc

+5v_enc

not used

not used

enable

pwm_v_hi

ext_bat

/status

status

/pwm_u_lo

pwm_u_hi

chu_lo

pwm_w_hi

/pwm_w_lo

/pwm_v_lo

+5v_enc

cha_lo

cha_hi

not used

encoder reset pin

b channel output

frame ground

z channel output

+v (battery)

0v (battery)

a channel output

/z channel output

/b channel output

/a channel output

5v (power supply)

0v

I

/I

I

/I

1

a

b

a

b

1

2

2

/enable

shield

pwm_a

l

l

/pwm_c

/l

enable

pwm_c

/l

/pwm_a

pwm_b

/pwm_b

/status

status

a

a

b

b

Connector On End of Cable

Cable Type

Connector On End of Cable

Max. Cable Length

44--pin Miniature D-shell (has pins)

8520-MD44M

Belden 8312 (encoder cable)

Belden 9833 (drive signal cable)

MS Style E20-29S

8520-C17F to encoder

1

Honda MR-25LF (has

sockets) 8520-H25F to drive

2

25m (82 ft)

1

The Z channel output is used for the marker signal.

2

These cables are 22 AWG twisted pairs. Multiple lines (4) must be used to provide the equivalent of 16 AWG encoder power leads.