Shunt resistor selection chart – Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 654

Section 13A

Connecting 8520 Digital Drive Systems

13A-20

Where:

- J = total motor and axis inertia measured at motor shaft, summed for

all motors connected to the servo amplifier [Kg cm s

2

]

- N = maximum motor speed [rpm]

- T = desired deceleration time from maximum motor speed to stop

[sec.]

Important: These equations are for approximating shunt resistor

requirements. They can produce worst case data that is unrealistic for most

applications. For example, in most machine tool applications it is unlikely

that all axes will ever be traveling simultaneously at their maximum speed.

Factor the type of duty expected for your machine into these equations.

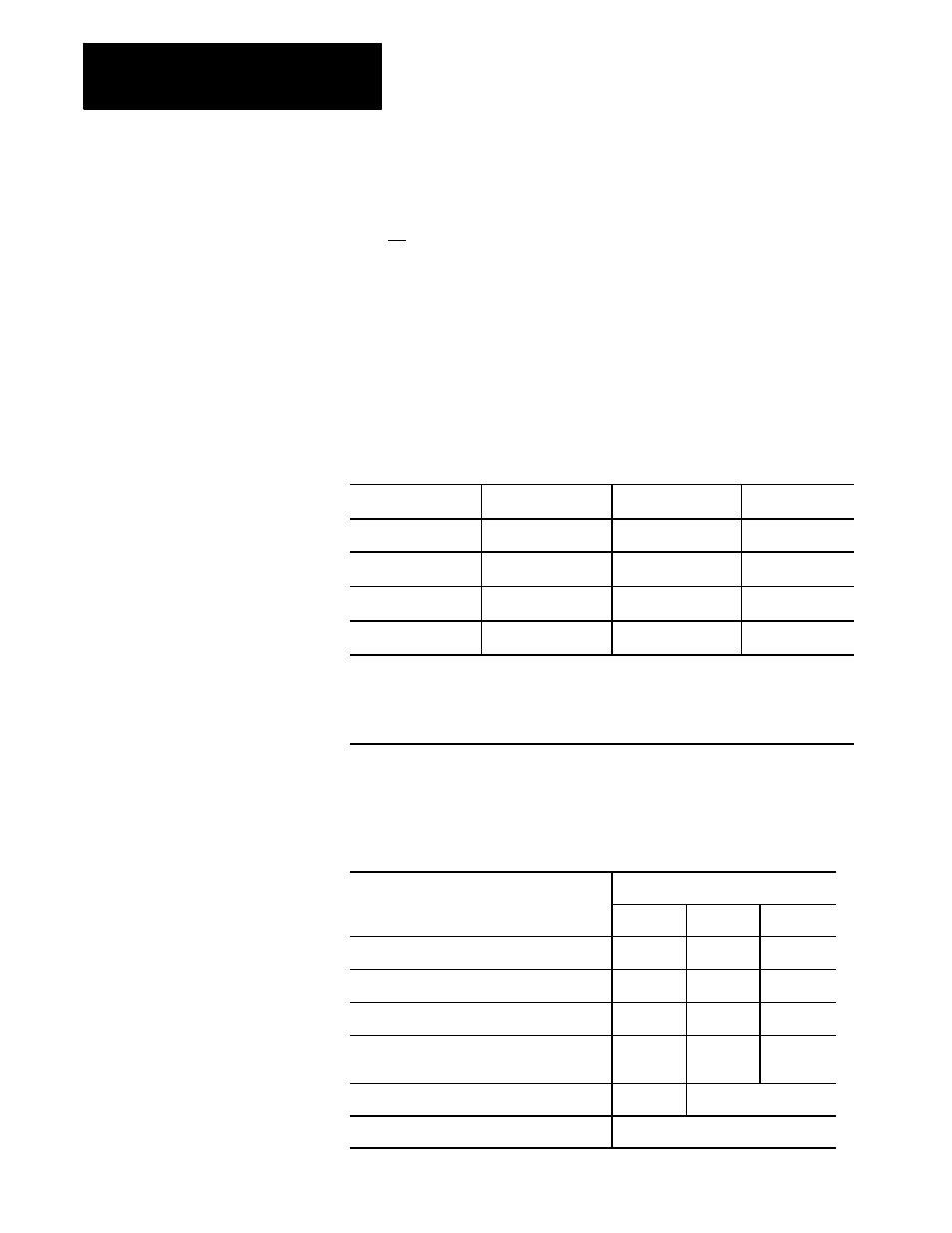

Shunt Resistor Selection Chart

P

< 1100

1100

£

P

< 1800

1800

£

P

W

< 180

Shunt Option #1

Shunt Option #2

1

180

£

W

< 540

Shunt Option #2

Shunt Option #2

1

540

£

W

< 810

Shunt Option #3

Shunt Option #3

1

810

£

W

2

2

2

1

Not possible with current configuration. Move one or more motors to another servo amplifier, or reduce

inertia, or reduce motor speed.

2

Not possible with current configuration. Move one or more motors to another servo amplifier, or reduce

inertia, or reduce motor speed, or increase time from maximum speed to stop.

Table 13A.M lists the internal/external shunt resistor, contactor, and fuse

specifications.

Table 13A.M

Internal/External Shunt Specifications

Specifications

Shunt Options

Option #1

Option #2

Option #3

Shunt Location

Internal

External

External

Shunt Resistance

16 ohms

10 ohms

10 ohms

Shunt Continuous Rating

196 watts

600 watts

900 watts

Shunt Duty Cycle Limit (determined by servo

amplifier jumper settings)

2 sec

5 sec

5 sec

Shunt Fuse Rating

15A/600V non-time delay

Shunt Contactor Size

15A/600V or greater