Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 854

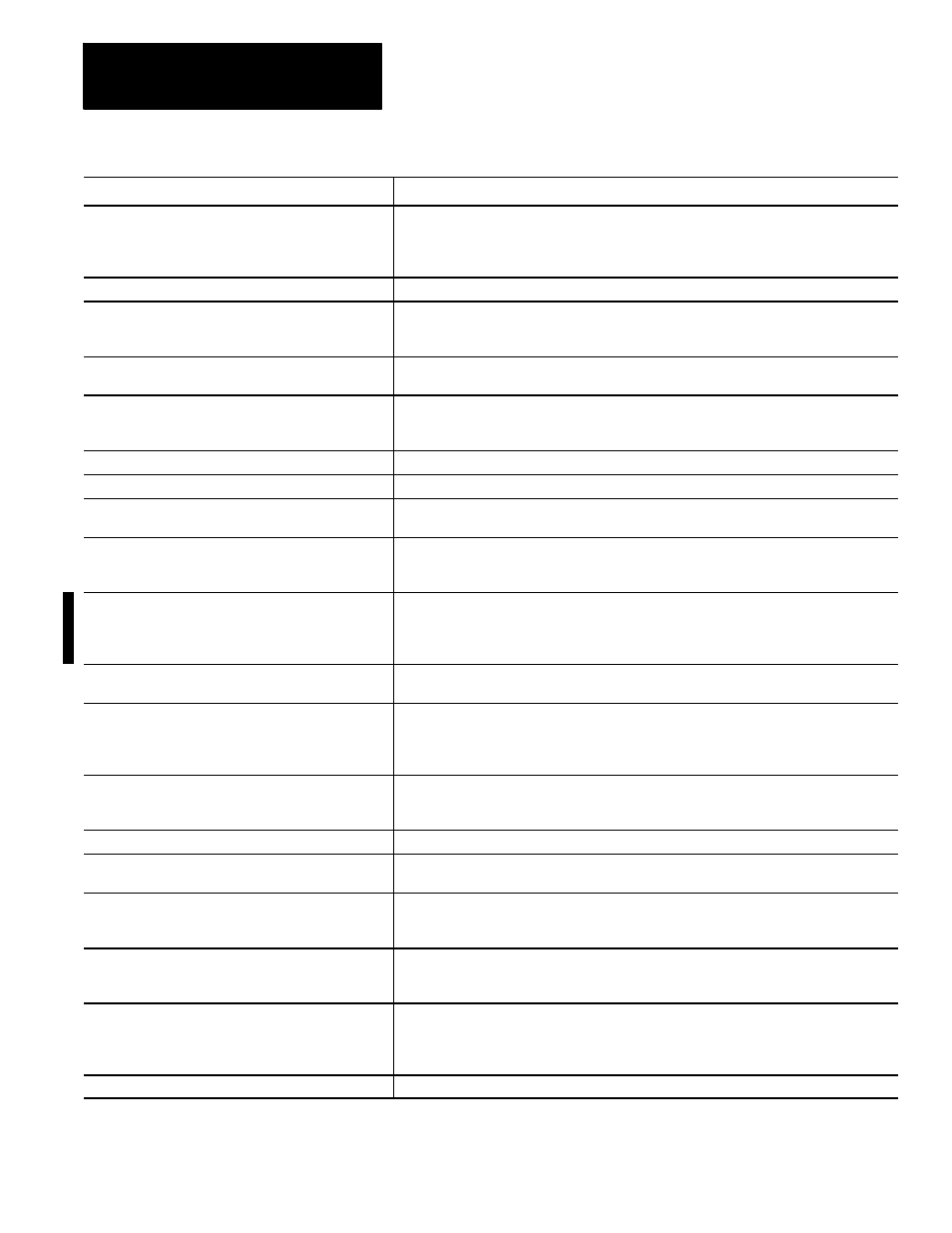

Error and System Messages

Section 16

16-34

Message

Description

PLUNGE MOTION NOT PROGRAMMED

In your pocket cycle you have either not programmed a final depth, or the final depth you have

programmed is equal to the depth of the cutting tool at the starting point of the cycle. The

location of the cutting tool when the pocket cycle is programmed must be at a different depth

than the final programmed depth of the cycle.

PLUNGE NOT ALLOWED

A plunge that will cut into the pocket wall was requested in a G89 irregular pocket cycle.

PLUNGE STEPS MIS--PROGRAMMED

The rough, medium, and fine-feed depths in the cycle block are not programmed correctly. This

is possible if the data in the block is incorrect or if the data in the modal values of the parameter

not programmed in the block are incorrect.

POCKET END NOT SAME AS START

A pocket end-point that is not the same as the pocket start-point was programmed in a G89

irregular pocket cycle.

POCKET IS PART OF CUSTOM TOOL

An attempt was made to assign a tool to a tool pocket that is already used by a custom tool.

Custom tools are assigned to tool pockets that are shown with an XXXX next to the pocket

number on the random tool table.

POCKET MILLING SHAPE IS INVALID

A parameter is missing in the G88 programming block.

POINT ALREADY EXISTS

The point that you are trying to enter is already in the axis calibration table.

PORT B IS BUSY

This message appears when you press {SYSTEM SUPORT}, {MONITOR}, or {SERIAL I/O} and

port B is busy.

PORT IS BUSY - REQUEST DENIED

An attempt was made to output or input information to or from a serial communications port that

is already being used by some other device or is selected as the port that an active program is

coming from.

POWER DOWN ERROR, POSSIBLE PAL DATA LOSS

This message can be displayed on power up of the contol. When it occurs, it indicates that the

control was shut doen abnormally , possible from a control “watch--dog time out”. You must take

appropriate steps to insure that the PAL program can still function properly with loss of

temporary data.

PREVIOUS ABORT COMMAND NOT COMPLETE

This message is displayed when the communications “abort”key is entered before the last abort

requested has completed.

PROBE/CONTROLLING AXIS CARD DIFFERENT

Both the adaptive depth probe and the adaptive depth probe controlling axis (typically the axis

that positions the probe) must be attached to the same servo card. You must re-AMP your

system and re-arrange your servo wiring so that the adaptive depth probe and it’s corresponding

servo are on the same servo card.

PROBE CYCLES CALCULATION ERROR

The servo module was unable to compute the probe position when the probe is fired. Make

sure that all measurement points are within the programmed range entered for the probe cycle.

Lower the feedrate during the probing operation and try again.

PROBE CYCLES PROGRAMMING ERROR

Either not enough or too many axes are programmed in a probing cycle block.

PROBE ERROR

A probing cycle has reached the outer limits of the tolerance band without firing the probe, or the

probe has fired before entering the tolerance band.

PROBE IN USE BY OTHER PROCESS

On a dual processing control only one probing function is allowed at any one time. Probing can

not be performed by both processes simultaneously. You must wait for probing to complete in

one process before probing in the other process.

PROBE IS ARMED, CAN’T ADJUST SERVOS

With the probe armed through a probing operation, until the probe fires or the probe is disarmed,

other online AMP servo parameters like torque, feedforward percentage, gain, etc., are not

allowed to be changed.

PROBE TRIP DURING DECEL

An adaptive depth probe trip occurred after the program block reached endpoint. The trip was

made while the control was waiting for the following error to collapse after interpolation is

complete. Avoid this error by reducing axis speed (thus reducing following error) or by moving

the adaptive depth block endpoint further into the part.

PROCESS SWITCH NOT CURRENTLY ALLOWED

On a dual-processing system, you cannot switch processes while in graphics or in digitize.