Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 51

Section 2A

Planning Your System Layout

2A-6

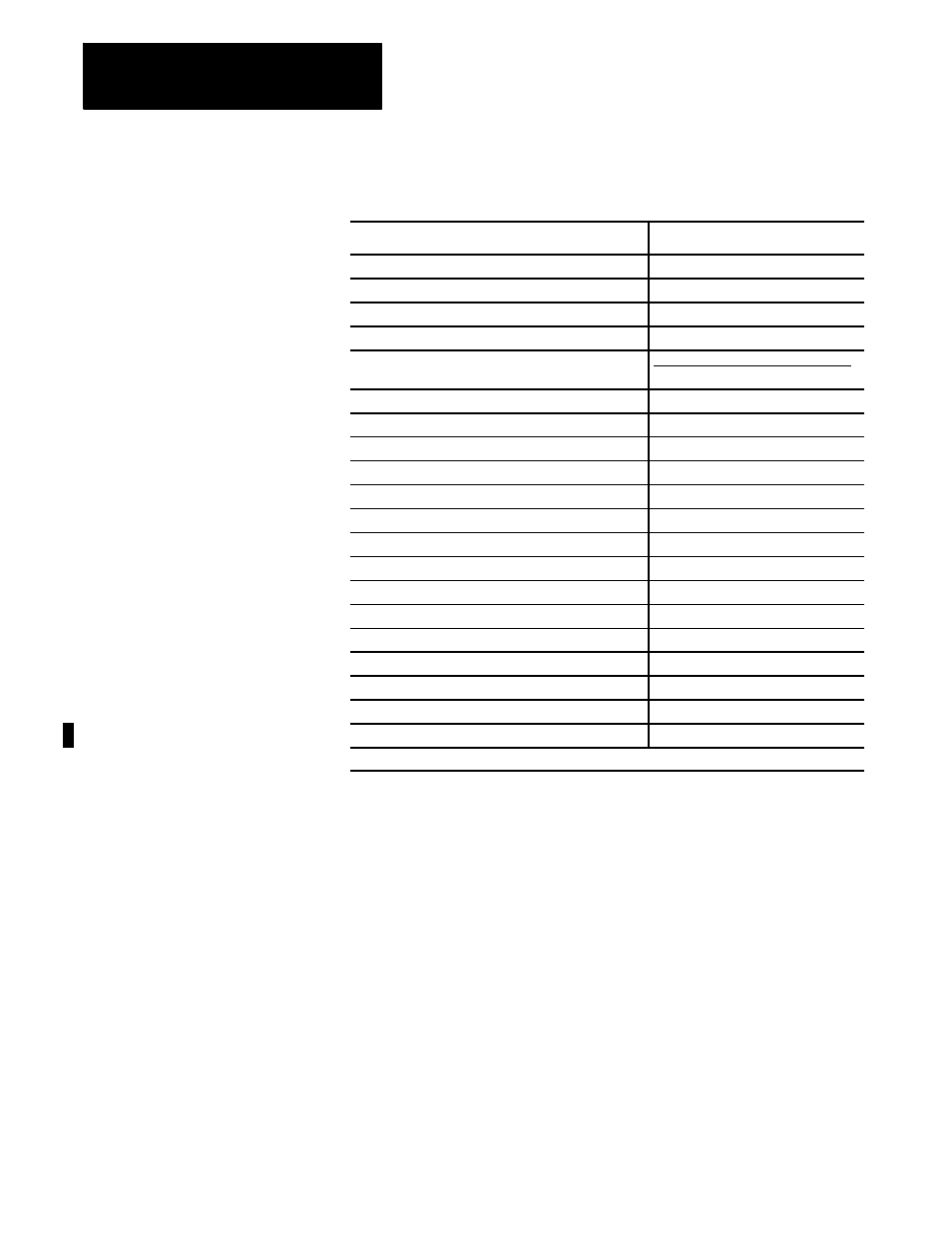

Table 2A.B

Component and Module Heat Generation Wattages

Component or Module

Heat Generation Wattage (W)

9/230 and Main Power Supply

130

9/260 or 9/290 and Main Power Supply

225

9/440 CNC/1394 Drive 5kw System Module

(@100%)

80

9/440 CNC/1394 Drive 10kw System Module

(@100%)

98

9/440 Axis Modules/1394 Drive

(each module @100%)

AM03

AM04

AM07

AM75

48

63

93

346*

9/440 CNC Power On/Off Control Module

5

Portable Operator Panel Interface Assembly

72

Monochrome Operator Panel

125

Color TFT Operator Panel (flat panel)

55

Color CRT Operator Panel

175

MTB Panel

15

HPG

1.2

3-axis Digital Servo Module

13.5

3-axis Analog Servo Module

14

4-axis Digital Servo Module (8520-ENC4)

15

4-axis Analog/1394 Servo Module (8520-SM4)

14

1746I Ring Adaptor (module only)

0.9

1771-HTE Termination Panel

0

MTB Panel I/O Module

5

Remote I/O Module (8520--RIOM)

4.2

* 18 Watts in cabinet, 328 Watts out through cabinet heat sink

The temperature rise inside a metallic cabinet incorporating only an

internal convection cooling fan can be roughly calculated with the

following formula:

T = W/6S

- T = Temperature rise in cabinet (

°

C)

- W = Heat generation (Watts) by units and modules

- S = Heat radiation surface area (sq. meter) of cabinet

(total cabinet surface area minus any area in contact with the floor or

building wall)

The above equation assumes a closed cabinet with heat dissipated only

through cabinet radiation.