11a.2 resolver feedback – Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 608

Section 11A

Connecting 1394 Digital Drive Systems

11A-3

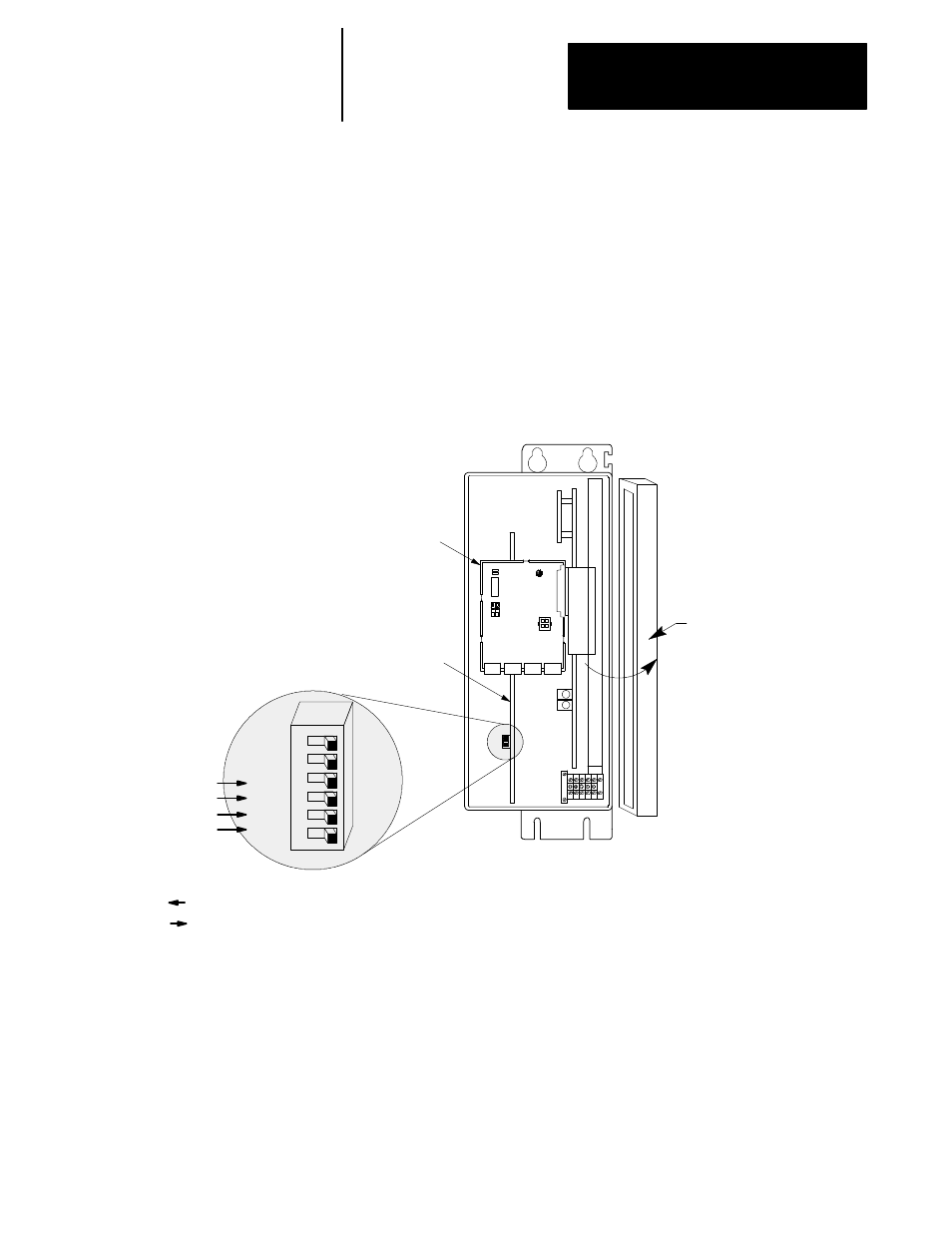

The 1326 servo motors that interface to the 1394 drive rely on resolvers

mounted directly to the motor for proper commutation. For these resolvers

to be properly interfaced to the 9/Series CNC their feedback must be

converted to an A quad B signal. This is accomplished by the CNC

interface board which takes the resolver feedback from the wiring board

and converts it into an A quad B signal before sending this signal on to the

9/Series CNC.

A dip switch (SW1) on the CNC interface board determines the number of

encoder counts per revolution this resolver feedback is translated into. The

bottom four switches of dip switch SW1 selects between 8192 or 32768

counts per motor revolution as follows:

Switch SW1

Left (away from Interface Board) = 32768 counts

Right (towards interface board) = 8192 counts

CNC Wiring Board

CNC Interface Board

System Module

ASRN 0

ASRN 1

FB3

FB2

FB1

FB0

Open Cover

Press Cover

Release to Open

These switches set the number of counts per/rev for each feedback device

connected to this 1394 drive. CNC1 corresponds to the feedback device

connected to FB0, CNC2 corresponds to the feedback device connected to

FB1, etc.. You must also indicate your dip switch selections by selecting

the appropriate number of counts per motor revolution in AMP for each

servo.

11A.2

Resolver Feedback