Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 842

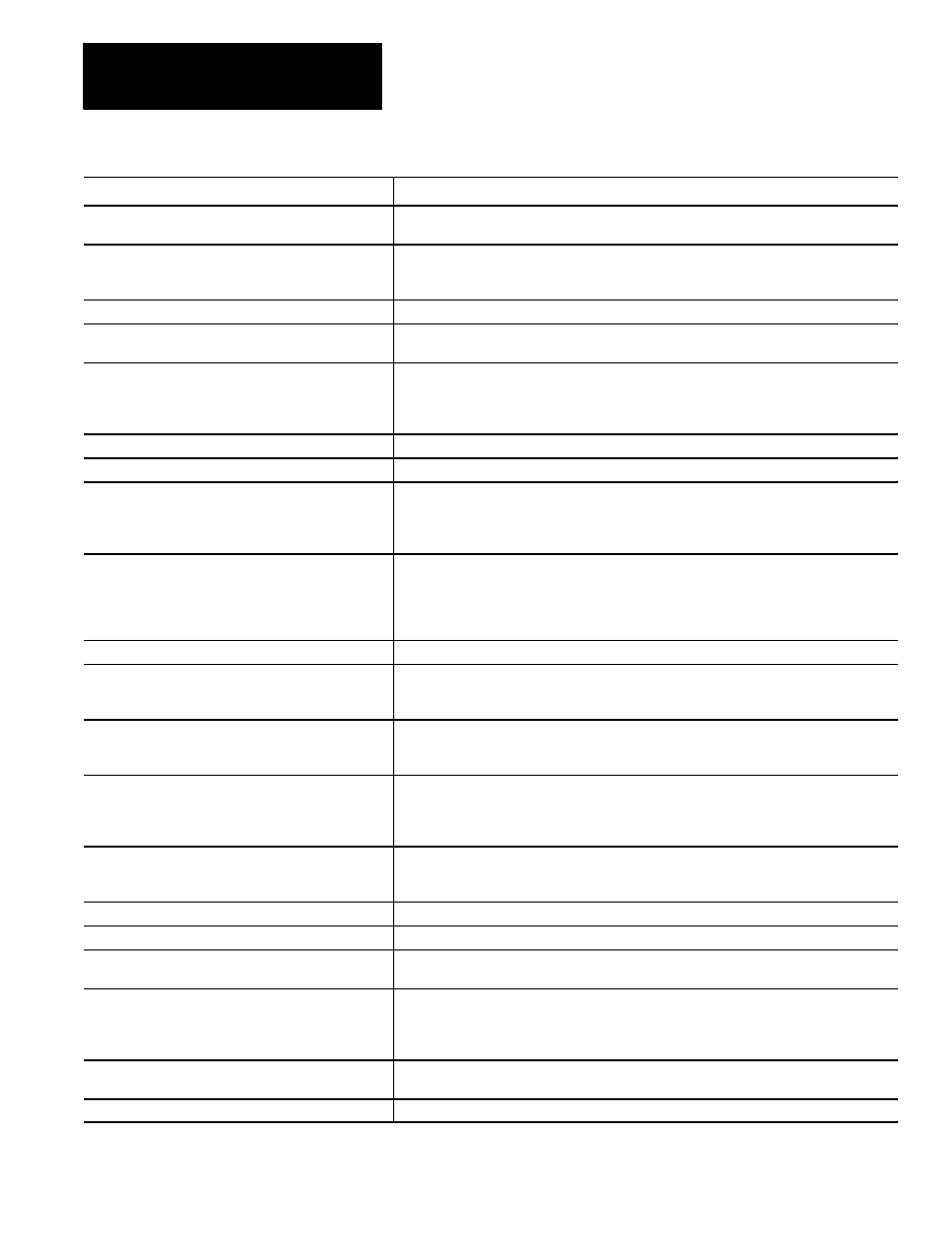

Error and System Messages

Section 16

16-22

Message

Description

INVALID PARAMETER VALUE

An attempt was made to assign an invalid value (typically too large or too small of a value) to a

paramacro parameter.

INVALID POCKET NUMBER

An attempt was made to enter a tool pocket number that exceeds the allowable number of tool

pockets in the random tool table. This error occurs when a P-word that is too large or too small

is programmed in a G10.1L20 block.

INVALID POCKET PROFILE

An invalid pocket profile was programmed in a lathe roughing or finishing cycle.

INVALID POSITION FB TYPE

System was incorrectly AMPed with a Yaskawa type encoder (absolute or incremental) on the

position feedback device when separate position and velocity feedback devices are used.

INVALID PROGRAM NUMBER (P)

A program number called by a sub-program or paramacro call is invalid. A P-word that calls a

sub-program or paramacro can only be an all-numeric program name as many as 5 digits long.

The O-word preceding the numeric program number in control memory cannot be entered with

the P-word.

INVALID REMOTE NODE NAME

An error occurred in G05 DH+ communications block.

INVALID REMOTE STATION TYPE

An error occurred in G05 DH+ communications block.

INVALID REPEAT COUNT (L)

An L parameter that programs the number of times a paramacro or other operation is to be

repeated was programmed incorrectly or out of the legal range. The L-word for repeat count

must be a whole, positive number. Decimal values and negative values are invalid. The

maximum value of an L-word is 9999.

INVALID ROUGHING CYCLE (P/Q) WORD VALUE

When executing a roughing cycle, the starting or ending sequence number of the contour

defining blocks cannot be found in the currently executing program. The sequence number of

the contour blocks is programmed using the P and Q words. These blocks can be anywhere in

the program provided they are resident in the same program, sub-program, or paramacro

program that contains the calling block.

INVALID SCALE FACTOR (P-WORD)

An invalid scale factor has been specified. The P-word has a range of 0.0001 to 999.99999.

INVALID SERVO HARDWARE TYPE

The AMP servo parameter that selects the servo type does not match the hardware found on

the control when the AMP file is downloaded. Either AMP is misconfigured or the servo

hardware installed on your system is not correctly installed or not of the correct type.

INVALID SHAFT POCKET

When entering a custom tool in the random tool table, an attempt was made to assign a shaft

pocket position that is not in the range of the number of pockets assigned to the tool. The shaft

pocket number must be equal to or less than the number assigned for the number of pockets.

INVALID SHAFT POCKET VALUE

A program is attempting to enter a custom tool in the random tool table with a invalid shaft

pocket position (not in the range of the number of pockets assigned to the tool). The shaft

pocket number must be equal to or less than the number assigned for the number of pockets.

The shaft pocket value is assigned in a G10.1 block following the R-word.

INVALID SPCMD VALUE

A invalid special command error typically occurs when the servo PROMs are not compatible

with the main processor PROMs. Check the software version numbers and contact

Allen-Bradley customer support services.

INVALID SYMBOL NAME

An error occurred in G05 DH+ communications block.

INVALID T-CODE FORMAT

This is an invalid T-Code Format

INVALID_THREAD_ANGLE

An attempt was made to program an angle that is outside the allowable range, which is 0

through 120 degrees.

INVALID THRESHOLD RATE

An invalid threshold percentage was entered for a tool group while setting tool management

data. The threshold percentage must range between 0 and 100 percent. Only whole positive

numbers can be entered. If using a G10 block, the threshold percentage is entered with a

Q-word.

INVALID TIME FORMAT MUST BE HH:MM:SS

An invalid time format was entered. The time format must be hour / minute / second

(HH/MM/SS).

INVALID TOOL AXIS

This is an invalid Tool Axis.