Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 700

Integrating a Split Axis with Deskew

Section 14B

14B-6

8.

Loosen the encoders for both servos. In most cases, you can loosen

the encoder casing from its mounting without disengaging the

encoder shaft. This way you can rotate the encoder and change its

position reading without moving the axis.

Important: On all digital servo motors and some analog servo systems,

rotation of the encoder relative to the motor is not possible. The encoder is

mounted relative to the motor shaft at a specific location and cannot be

moved. In these cases it is necessary to disconnect the servo drive linkage

and rotate the motor shaft to align encoder markers.

9.

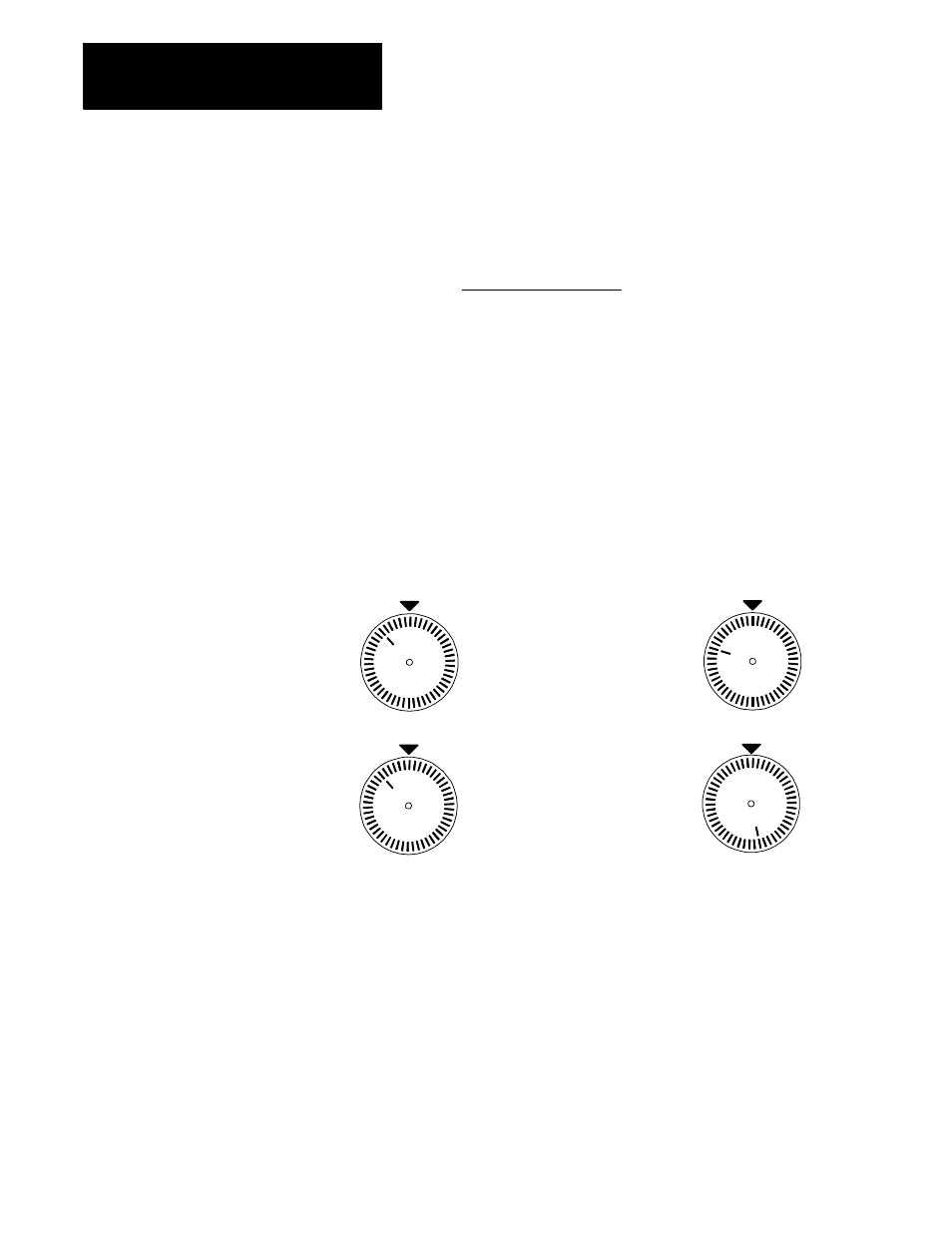

Align the two servos’encoder markers. Align the encoder markers

by rotating the encoder casing until the DISTANCE TO MARKER

value on the display for each servo is as close to the same value as

possible. Refer to Figure 14B.3.

Figure 14B.3

Aligning Master and Slave Encoder Markers

CORRECT

INCORRECT

SLAVE

MASTER

Master and slave

encoder markers are

aligned within a few

counts of eachother

Master and slave

encoder markers are not

aligned, resulting in a

significantly different

distance to marker between

the servos when homing.

SLAVE

MASTER

10. Tighten the encoders for both servos. This will assure that both

servos are approximately the same distance from their markers when

there is minimal axis skew.

11. Loosen the clamps or remove the weight you used to secure the axis

in step 6.

12. Turn power to the control off and then back on again. When power is

turned back on the servos will assume that they are in position and

will hold the axis at minimal skew, this time with encoder markers

aligned.