9 remote i/o modules – Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 452

Section 8

Communication Interface

8-19

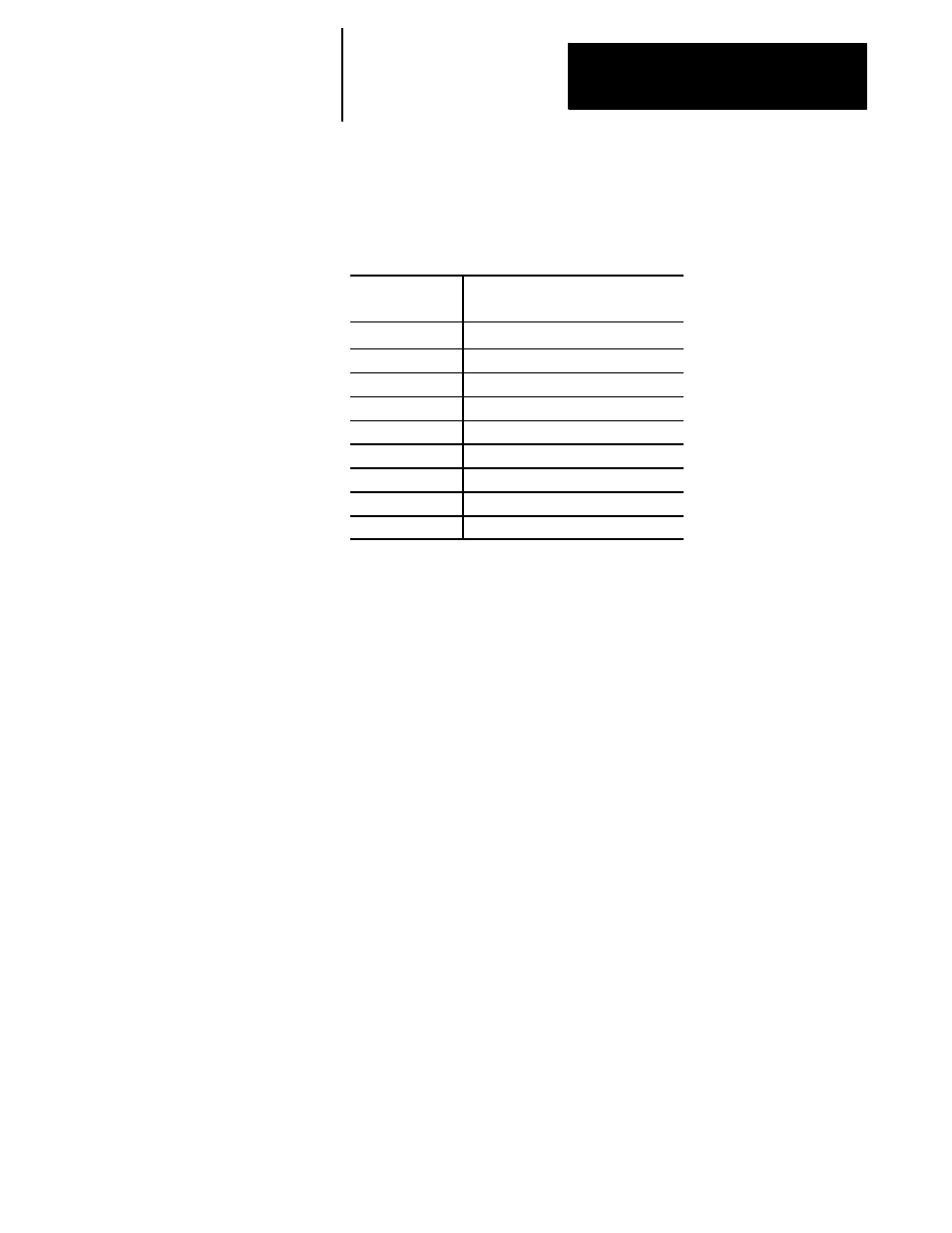

6. Epson LX-810 Printer Connection

The recommended configuration of the Epson LX-810 printer is shown

below:

Configuration

Parameter

Setting

DEVICE:

Epson LX--810

PORT TYPE:

RS232C

BAUD RATE:

2400

PROTOCOL:

LEVEL_2*

PARITY:

EVEN

STOP BITS:

1

DATA LENGTH:

8

TIMEOUT:

15 SEC

OUTPUT CODE

N/A

The remote I/O modules allow the 9/Series control to appear as a remote

I/O rack to the I/O scanner of a PLC processor. There are two separate

remote I/O modules, one for 9/260 controls, and one for 9/290 controls.

9/230 and 9/440 controls, equipped with remote I/O, have the remote I/O

circuitry and connections mounted directly on the processor or wiring

board respectively. Though the remote I/O link performs the same

functions and is configured in the same manner for all the 9/Series

controls, the installation and appearance is significantly different between

processors.

Remote I/O is a feature of Allen-Bradley’s 1771 I/O and is beyond the

scope of any 9/Series documentation. For details on the operation,

configuration, and capabilities of a remote I/O device on the 1771 I/O

network refer to documentation that came with your 1771 I/O system.

This document only discusses what is necessary to install and troubleshoot

the 9/Series remote I/O modules.

Implementing Remote I/O on the 9/Series control

Important: PAL must set the $RMON flag TRUE, during the first

foreground execution, to enable the remote I/O connection. Also several

remote I/O operating parameters must be setup in AMP to configure the

remote I/O communications for your specific network. Refer to your

9/Series AMP and PAL reference manuals for details.

When remote I/O information is sent to the control, it is transmitted as

values from eight output words in the PLC processors output image table

8.9

Remote I/O Modules