Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 155

1

2

3

4

5

6

7

8

9 10 11 12 13

14 15 16 17 18 19 20

11278-I

Section 4B

Connecting the 3-axis Servo Module

4B-9

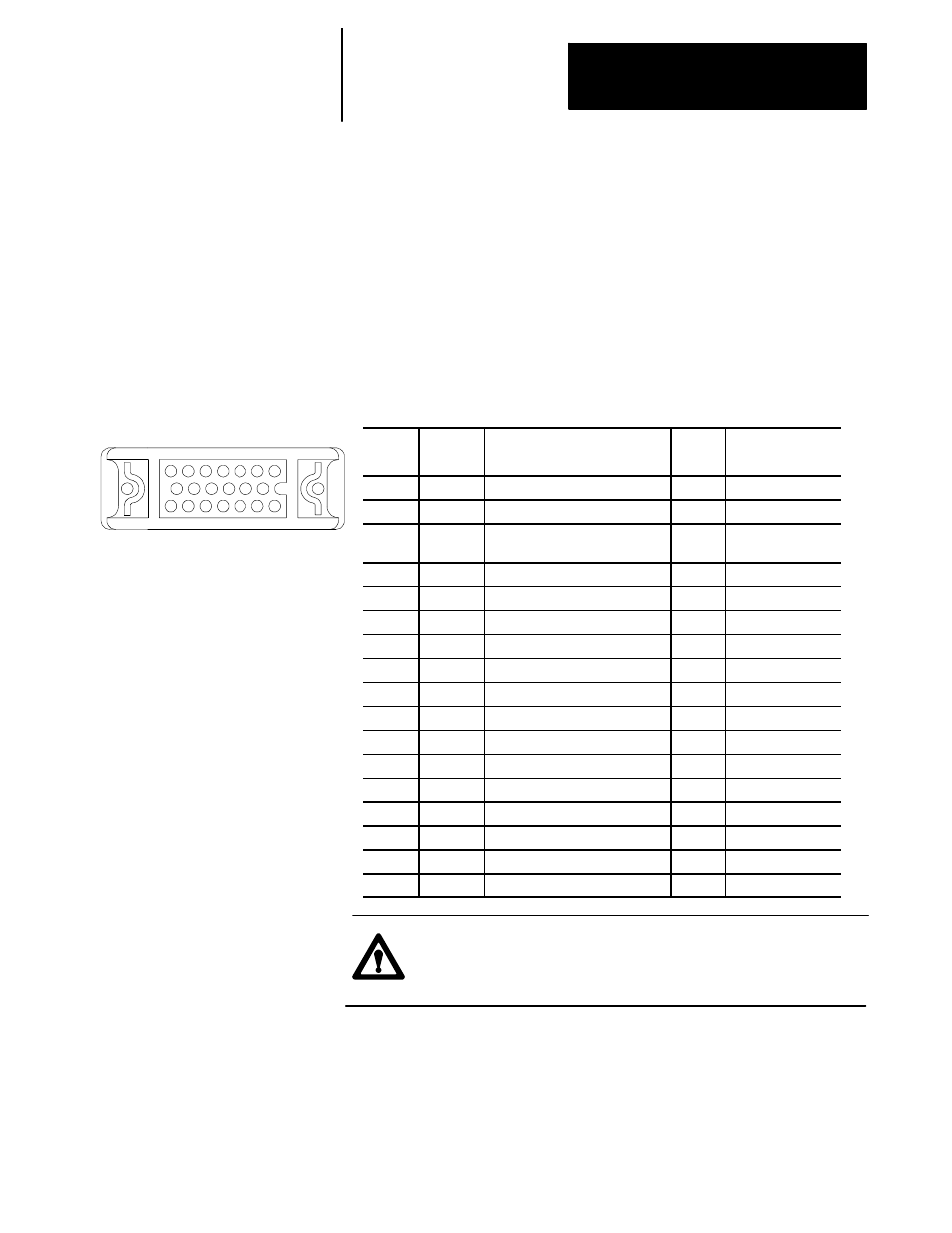

CN5, CN6, and CN7 for Absolute and Incremental Encoder Connectors

The digital servo module receives feedback from the feedback devices

(absolute or incremental encoders) of the servo motors or spindle through

connectors CN5, CN6, and CN7. Figure 4B.7 shows an end view of

connectors CN5, CN6, and CN7 and lists the pin assignments of this

connector when it is used with absolute encoders.

Figure 4B.7

Absolute Encoder Connections and Pin Assignments of Connectors

CN5, CN6, CN7, 20 pin female, Honda MR-20RFD2

Pin. No

Signal

Description

True

Level

Signal Destination

1

GND

Encoder Power Return

Feedback Device

2

GND

Encoder Power Return

Feedback Device

3

ENC_5V

Switched +5V Encoder Power

Supply

Feedback Device

4

ENC_5V

+5V Encoder Power

Feedback Device

5

ENC_15V +15V Encoder Power

Feedback Device

6

ENC_15V +15V Encoder Power

Feedback Device

7

BAT_+

Battery Power Supply

Feedback Device

8-11

N.C.

12

Reset

Used for Reset Operation Only

Feedback Device

13

N.C.

14

PZ

Phase_Z, 1 pulse per rev

High

Servo Module

15

/PZ

Diff. Signal

Low

Servo Module

16

PA

Phase_A, 2-phase pulse

High

Servo Module

17

/PA

Diff. Signal

Low

Servo Module

18

PB

Phase_B, 2-phase pulse

High

Servo Module

19

/PB

Diff. Signal

Low

Servo Module

20

Shield

Chassis Ground

Servo Module

ATTENTION: Reversing the polarity of the absolute encoder

battery power supply can destroy some elements of the absolute

encoder.