Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 156

Section 4B

Connecting the 3-axis Servo Module

4B-10

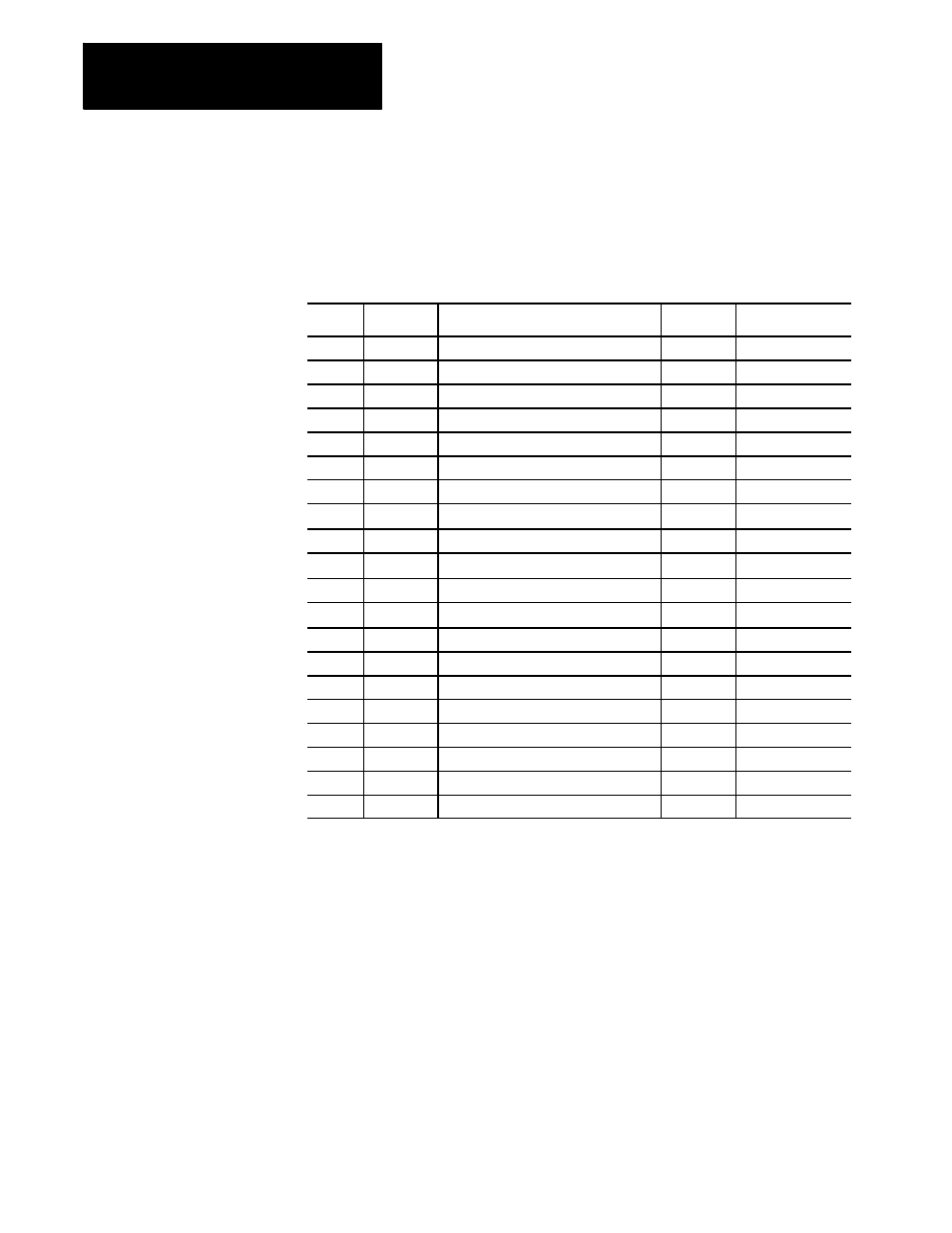

Table 4B.B lists the pin assignments of this connector when it used with

incremental encoders.

Table 4B.B

CN5, CN6, and CN7 Incremental Encoder Pin Assignments

Pin No.

Signal

Description

True Level

Signal Destination

1

GND

Encoder Power Return

Feedback Device

2

GND

Encoder Power Return

Feedback Device

3

ENC_5V

Switched +5V Encoder Power Supply

Feedback Device

4

ENC_5V

+5V Encoder Power

Feedback Device

5

ENC_15V

Spindle Encoder +15V Power Supply

Feedback Device

6

ENC_15V

+15V Encoder Power

Feedback Device

7

N.C.

8

PU

Pole Sensor output Phase_U, 0

°

High

Servo Module

9

/PU

Diff. Signal

Low

Servo Module

10

PV

Pole Sensor output Phase_V, 120

°

High

Servo Module

11

/PV

Diff. Signal

Low

Servo Module

12

PW

Pole Sensor output Phase_W, 240

°

High

Servo Module

13

/PW

Diff. Signal

Low

Servo Module

14

PZ

Phase_Z, 1 pulse per rev.

High

Servo Module

15

/PZ

Diff. Signal

Low

Servo Module

16

PA

Phase_A, 2-phase pulse

High

Servo Module

17

/PA

Diff. Signal

Low

Servo Module

18

PB

Phase_B, 2-phase pulse

High

Servo Module

19

/PB

Diff. Signal

Low

Servo Module

20

Shield

Chassis Ground

Feedback Device

The encoder marker signal is sent to the control on the Phase_Z pins

(#14 and #15).

Important: If a spindle incorporates an encoder to supply position

feedback to the digital servo module, the spindle encoder must be

interfaced with the last open connector of these 3 connectors. Refer to the

AMP reference manual for additional information on digital servo board

configuration.

Pins 8 through 13 of connectors CN5, CN6, and CN7 are used for motor

phasing only. When using connectors CN5, CN6, or CN7 for spindle

feedback, pins 7 through 13 are not connected (N.C.).