13a.9.1 incremental encoder feedback interface – Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 665

A

B

C

D

E

F

G

H

J

L

M

N

P

R

S

T

K

Section 13A

Connecting 8520 Digital Drive Systems

13A-31

This value is then compared to the actual A channel frequency of the

encoder which is determined by the following formula:

(Lines/Rev.) x (Max. Operating RPM) x (min./60sec.)

As long as the actual encoder A channel frequency does not exceed the

maximum encoder channel frequency calculated above, the servo module

should process the encoder feedback data without a quadrature fault.

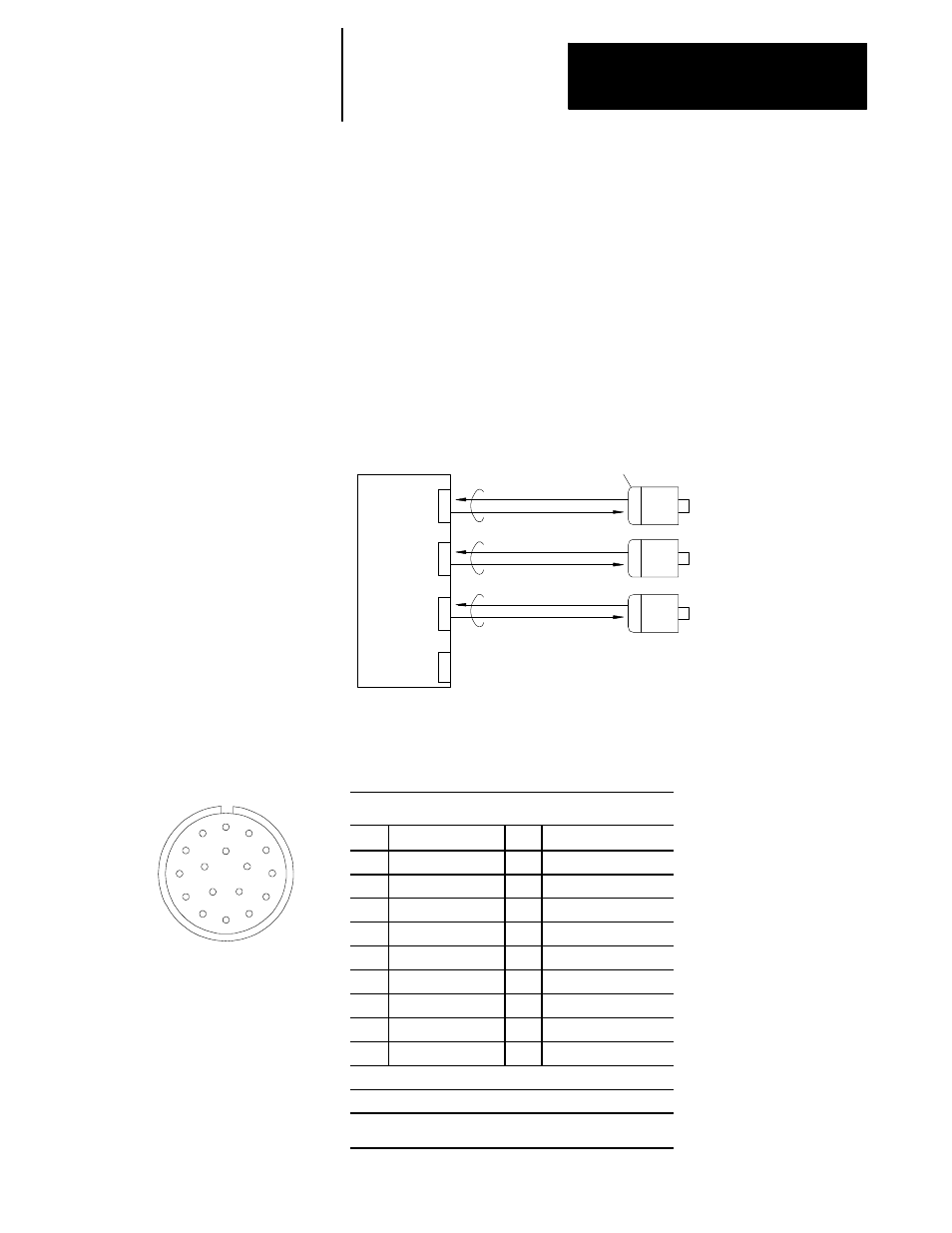

Figure 13A.5 shows the interface between the 8500 digital servo module

and servo motors with incremental encoders.

Figure 13A.5

Incremental Encoder to 8520 Digital Servo Module Interface

Feedback device

(incremental encoder)

Servo

motor

1

Servo

motor

2

Servo

motor

3

Channel signals (A, B, Z, U, V, W)

Power supply (+5V dc)

11092-I

Servo module or 9/230 CNC

Servo Connector

Servo Connector

Servo Connector

Analog Out

Figure 13A.6 shows the connector and pin assignments used to interface

the incremental encoder with the 8520 digital servo module.

Figure 13A.6

Incremental Encoder Feedback Connector and Pin Assignments

Incremental Encoder

Pin

Signal

Pin

Signal

A

A Channel Output

K

U Channel Output

2

B

/A Channel Output

L

/U Channel Output

2

C

B Channel Output

M

V Channel Output

2

D

/B Channel Output

N

/V Channel Output

2

E

Z Channel Output

1

P

W Channel Output

2

F

/Z Channel Output

1

R

/W Channel Output

2

G

0V

S

--------------------------------

H

+5V dc

T

--------------------------------

J

Frame Ground

--

--------------------------------

Connector Type: Cannon MS3102A20-29P

Signal Output Circuit: Differential Line Driver

1

The Z channel output is used for the marker signal.

2

The U, V, and W channels are used for motor phasing only

13A.9.1

Incremental Encoder

Feedback Interface