Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 414

Section 7B

Fiber Optic Connections

7B-2

Cable suspended in the air should be supported to withstand the load

produced by its own weight.

DOP, a plasticizer, commonly used with polyvinyl chloride insulated

wire (80% of wires) tends to degrade the acrylic core of fiber optic

cable. If fiber optic cable is tightly bundled with wire cables and these

cables are subjected to high temperature and humidity, the DOP in the

wire cable’s insulation may leech into the fiber optic cable and degrade

the core.

Fiber transmittivity may also be degraded if exposed to organic solvents

including, but not limited to:

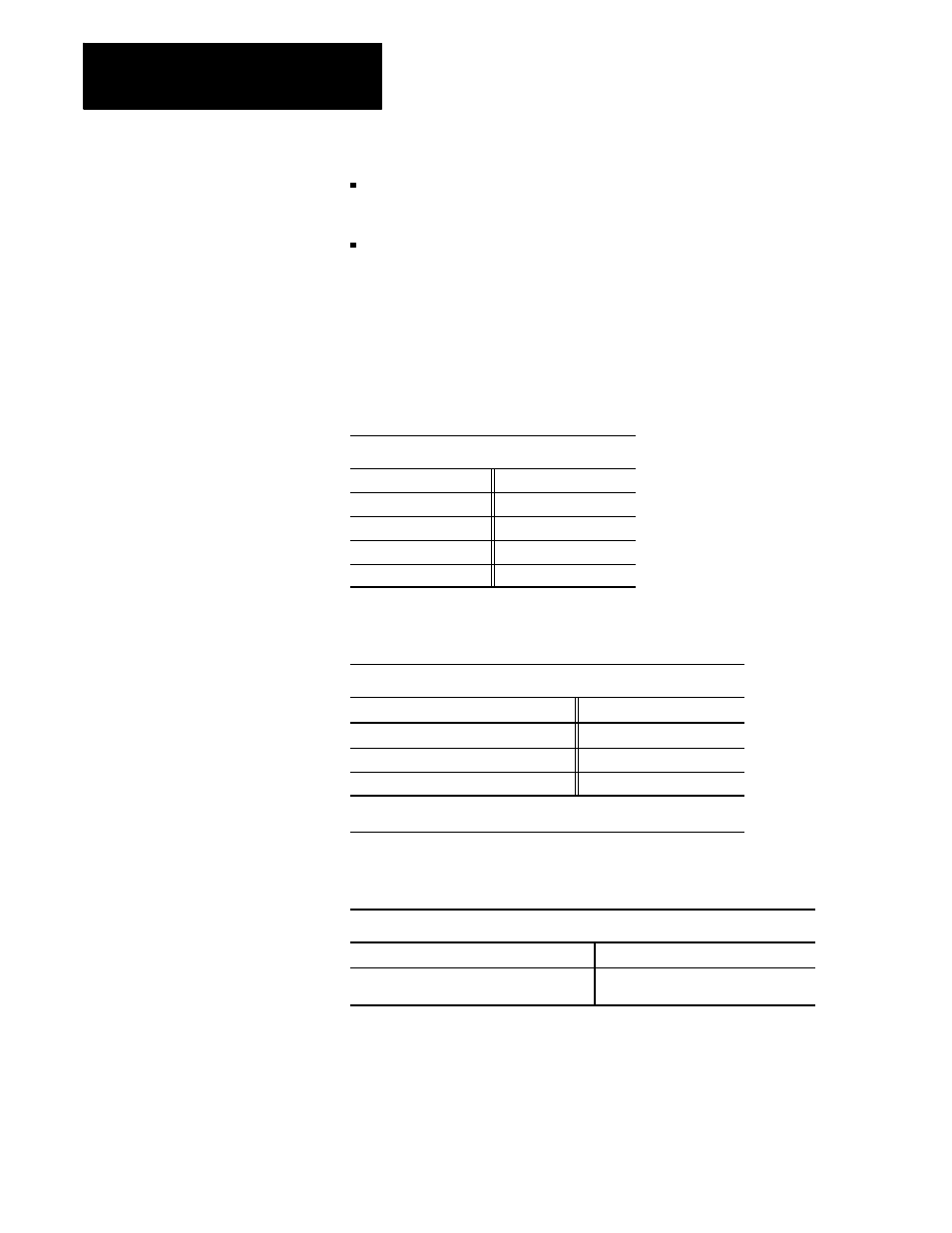

Common Solvents Degrading Transmittivity

acetone

methyl ethyl ketone

benzene

toluene

ethyl acetate

trichloroethane

gasoline

trichloroetholene

methanol

Fiber optic cable can be exposed to the following liquids for long terms

without transmittivity being degraded:

Cable Resistant to these Solvents

NaOH (10%) at 60

°

C

H2SO4 (10%) at 60

°

C

NH4 (5%) at 60

°

C

NaCl (5%) at 60

°

C

chlorinated hydrocarbon cutting oil

1

distilled water

mineral oil based dielectric fluid

1

1

The PVC jacket of the cable will be affected but fiber attenuation will not be

affected.

Fiber optic cable can be exposed to the following liquids for short terms

without transmittivity being degraded:

Cable Resistant to these Solvents for Short Term only

isopropyl alcohol

soap suds (0.5%) at 60

°

C

sodium phosphate based flux cleaners (0.5%

sodium phosphate synthetic detergent)

Ammonium hydroxide based flux

cleaners