Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 843

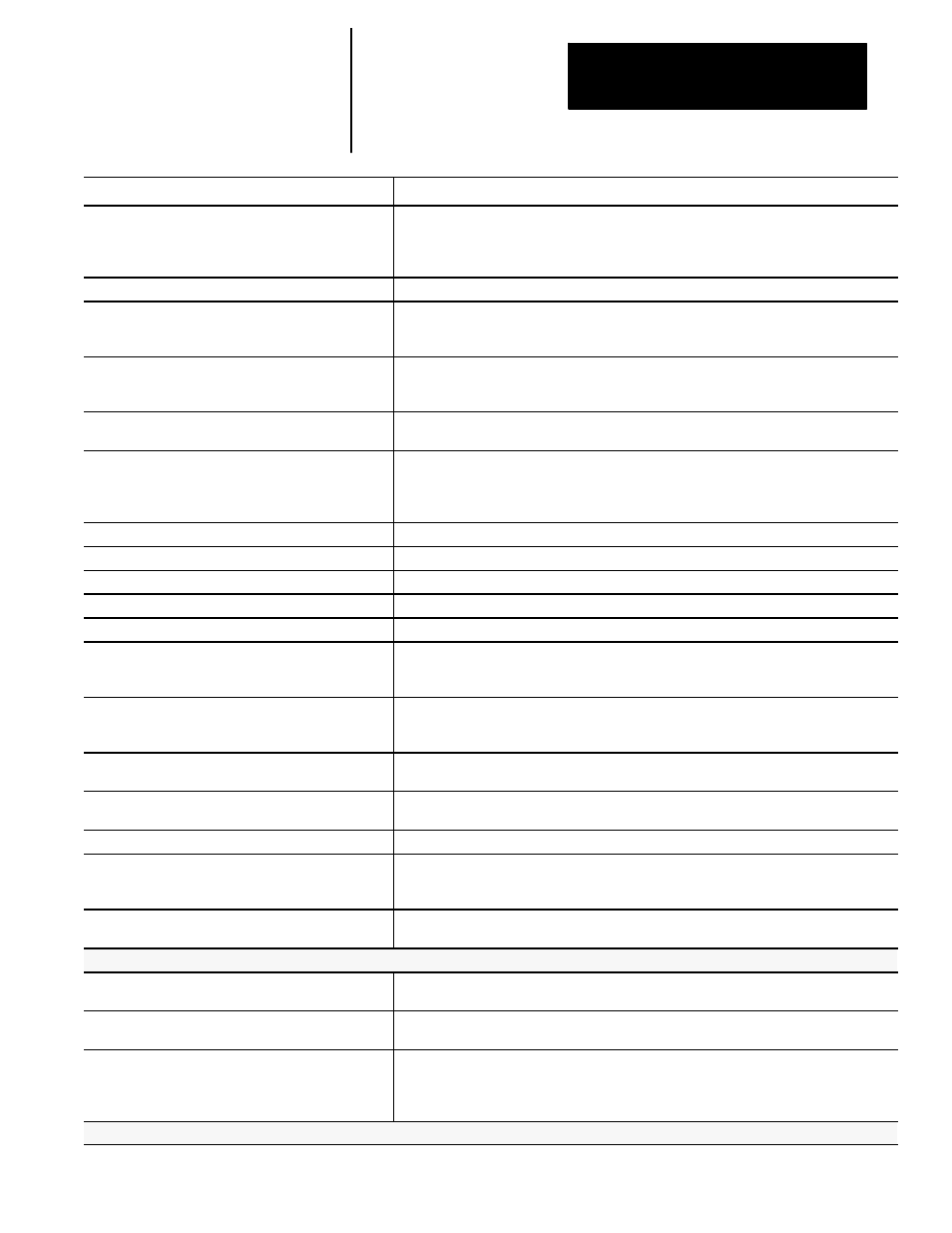

Error and System Messages

Section 16

16-23

Message

Description

INVALID TOOL CUTTER COMPENSATION NUMBER

An attempt was made to enter a tool radius offset number, for cutter compensation or TTRC, in

the tool life management table that is larger than the maximum offset number allowed. If the

tables are being loaded by a G10 program, the radius offset is entered with a D-word in the

block.

INVALID TOOL DIAMETER VALUE

An invalid tool diameter value was entered in a program block.

INVALID TOOL GROUP

An attempt was made to create a tool group greater than 200 in the tool management tables. A

maximum of 200 tool groups can be used. If loading the tables using a G10 program, the tool

group number is entered using a P-word.

INVALID TOOL LENGTH OFFSET NUMBER

An attempt was made to enter a tool length offset number in the tool life management table that

is larger than the maximum offset number allowed. If the tables are being loaded by a G10

program, the length offset number is entered with a H-word in the block.

INVALID TOOL LIFE TYPE

An attempt was made to enter an invalid tool life type for a tool group in the tool management

tables. Valid tool life types are type 0, 1, or 2.

INVALID TOOL NUMBER

Either no tool or an invalid tool number was programmed in a random tool G10.1 block. Tools

should be programmed with a Q-word in a G10.1 block or within a range determined by the

system installer in AMP. An invalid tool number was entered into the tool management tables or

was programmed in a part program block.

INVALID TOOL NUMBER FROM PAL

The PAL offset change feature specified an invalid tool number to the control.

INVALID TOOL ORIENTATION

This is an invalid tool orientation.

INVALID TOOL TABLE TYPE

This is an invalid tool table type.

INVALID VALUE ZONE 3

A zone 3 value was entered that is outside of the zone 3 limits.

INVALID VALUE ZONE 3:

The zone listed has values that are outside of the zone limits.

INVALID VELOCITY FDBK TYPE

AMP for your digital drive system has been configured for an invalid velocity loop hardware type.

Valid values for digital systems are NO FEEDBACK, ABSOLUTE FEEDBACK, and

INC ENCODER ON DIGITAL MODULE. Other selections are invalid on digital systems.

INVALID WHEEL ANGLE

An invalid wheel angle has been entered for the angled wheel grinder. Wheel angles must be

entered between 0 and 180 degrees. Also wheel angles that approach 90 degrees are also

invalid.

INVALID WORD IN G10L3 MODE

An attempt was made to assign a parameter that is not a legal parameter in the G10L3 mode.

G10L3 assigns data to the tool management tables.

INVALID WORD IN G11 BLOCK

An invalid word was programmed in a G11 block that cancels the data setting mode for the tool

management tables. The G11 code must be programmed in a block that contains no other data.

INVALID ZONE LIMIT

This is an invalid Zone Limit.

INVALID ’,’WORD

A word other than a chamfering C-word, a radius R-word, or QPP angle word was programmed

in a block with a comma “,”. Only the radius and chamfer words can be preceded with a “,”in a

block.

IPD AND G16.3/G16.4 CANNOT BE CONCURRENT

This error message is issued when in-process dressing is on and a block containing a G16.3 or

G16.4 is activated on a cylindrical grinder in angled wheel configurations.

J

JOG WILL CAUSE (+) OVERTRAVEL

An attempt was made to execute an incremental jog that would move the indicated axis beyond

its positive software overtravel limit.

JOG WILL CAUSE (-) OVERTRAVEL

An attempt was made to execute an incremental jog that would move the indicated axis beyond

its negative software overtravel limit.

JOGGED HOME TOO FAST:

The speed selected for the move to the home limit switch is too fast and the homing operation

has failed. Move the axes back to the other side of the limit switch (the side before the homing

operation began), and re-execute the homing operation, this time slowing the speed using the

L