10a.11 wiring i/o safely – Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 589

I/O Interface

Section 10A

10A-66

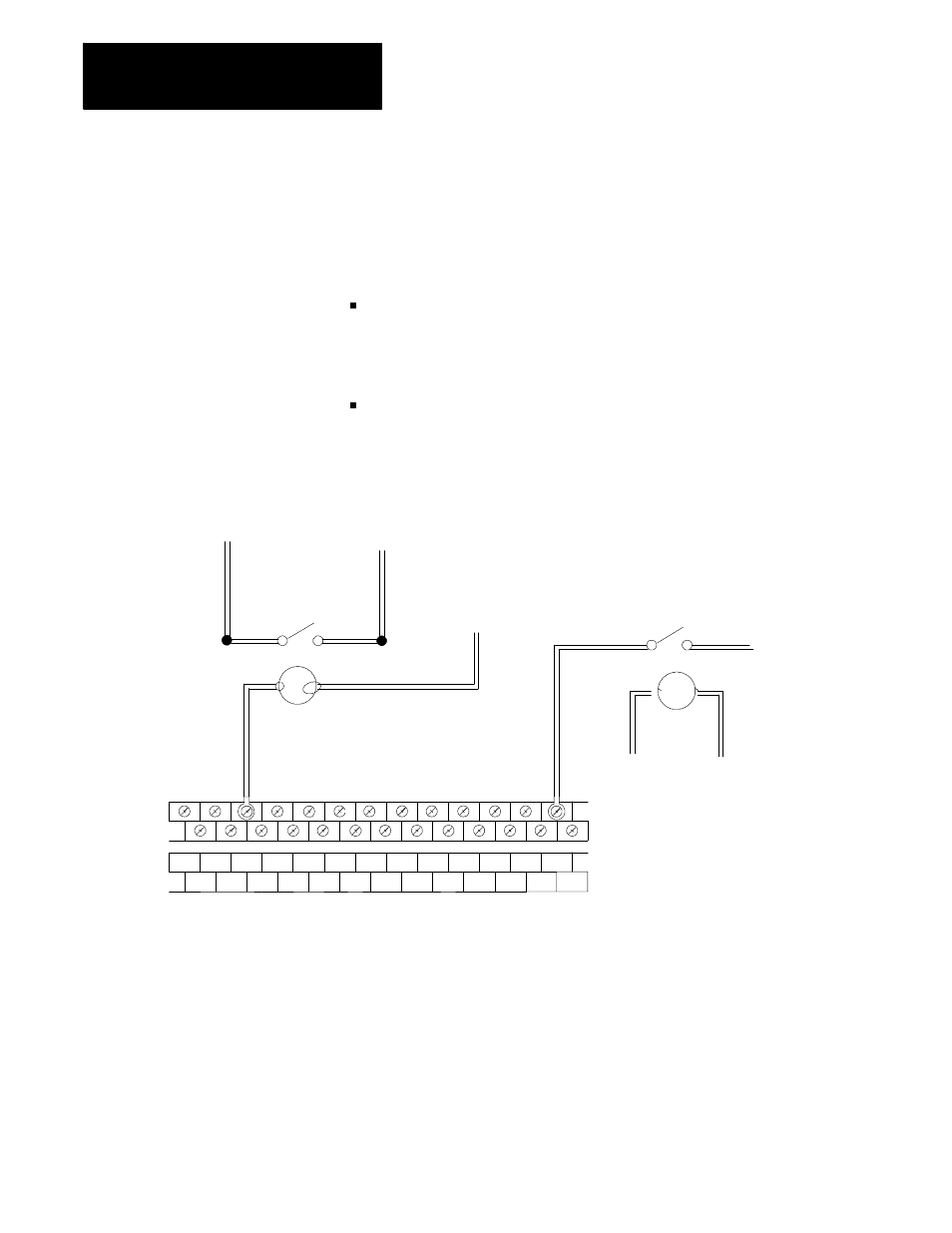

Many safety issues present themselves to the machine tool builder when

wiring I/O devices. Typically, 9/Series I/O devices attempt to maintain

their current status in the event of a system failure, I/O ring fault, or

E-STOP condition. Make sure that this is a safe state for your machine by

following these guidelines.

Make sure I/O is wired so power failure places the device in a safe

condition. For example if an output point controls an axis brake, you

would typically want the brake applied when the I/O device fails or

loses power.

Make sure I/O is wired so E-STOP condition places the device in a safe

condition. Remember E-STOP conditions do not reset I/O devices. I/O

devices attempt to maintain their last state when E-STOP occurred. For

example if an output point controls an axis brake, you would typically

want the brake applied when the E-STOP condition occurs.

Terminal

Block

Label

COM COM

COM

COM

COM COM

A01 A02 A03 A04 A05 A06 A07 A08 A09 A10

B01 B02 B03 B04 B05 B06 B07 B08 B09 B10

PB2

Customer supplied

brake relay

L2 (L)

R1

R1--1

Brake Circuit

When R1-1 is closed brake

is released.

L1 (H)

Energizes Brake Relay

R2--1

R2

E-STOP String

If E-STOP string is broken, brake is engaged.

Important: Notice in the above figure the E-STOP string only kills power

to the terminal blocks of the I/O module which in turn de-energizes the

brake relay. The actual I/O module on the I/O ring remains powered.

Killing power to the I/O device itself while the fiber optic ring is still

running can cause I/O ring fault errors.

END OF SECTION

10A.11

Wiring I/O Safely