Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 853

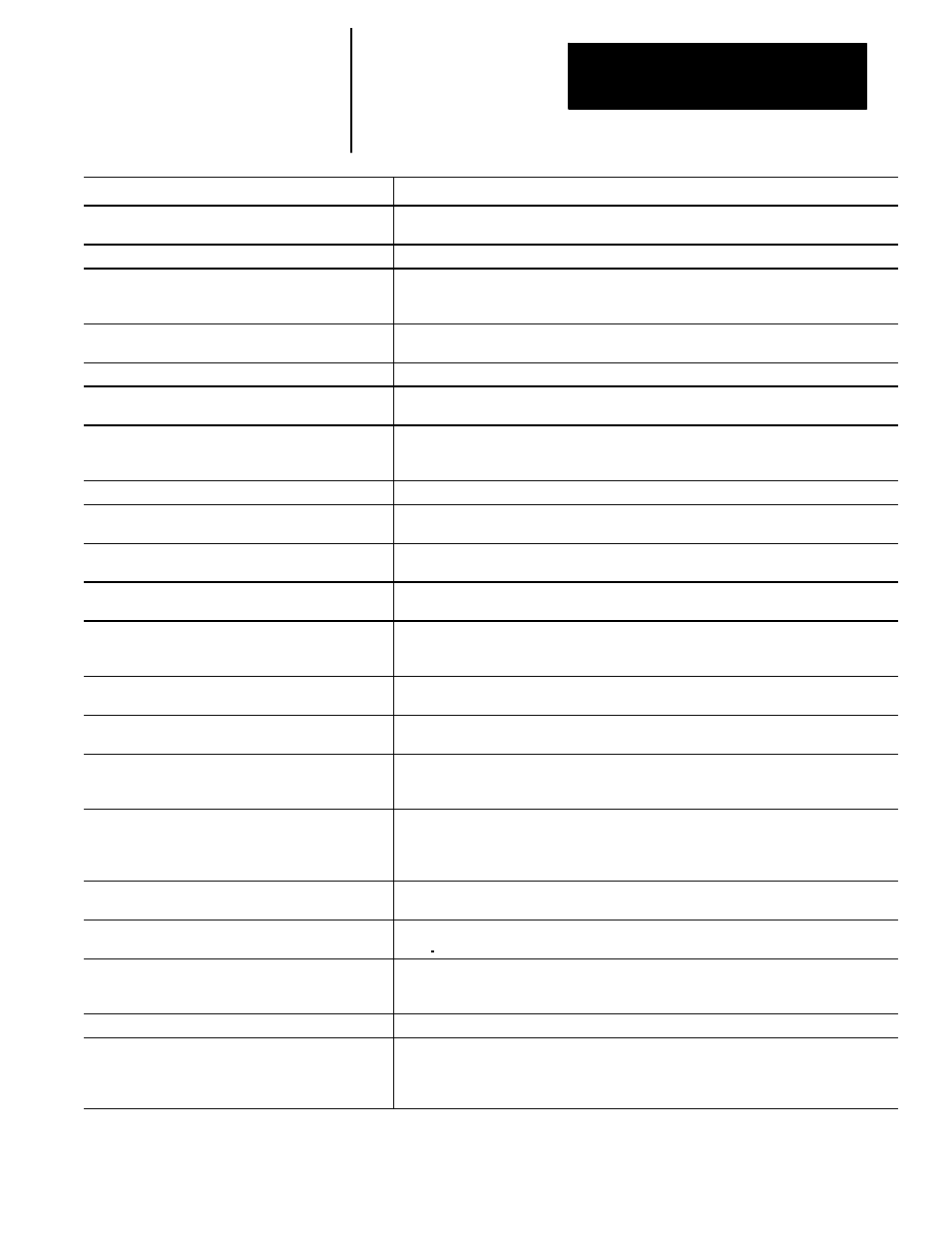

Error and System Messages

Section 16

16-33

Message

Description

PAL PAGE WAITING - EXIT MONITOR

A PAL display page is being overwritten by the current screen. Exit the search monitor utility to

see the screen PAL is attempting to display.

PAL PAGE WAITING - SCREEN HAS PROMPT

A PAL display page is being overwritten by the current screen.

PAL PROM CHECKSUM ERROR

Checksum error in the PAL PROM memory. This indicates PAL has been loaded successfully

however it has failed to pass verification. Check if your flash sticks are installed properly and

are not damaged. Attempt to download a copy of the same PAL image from another project.

PAL SOURCE NOT DOWNLOADED TO CNC

The PAL search monitor utility can not be accessed. The PAL search monitor utility requires the

PAL source code be downloaded with the built PAL program.

PAL SOURCE NOT LOADED

The copy of PAL in flash does not contain source programs.

PAL SOURCE REV. MISMATCH -- CAN’T MONITOR

PAL source code in the control does not match the revision of the CNC executive. The PAL

code may execute if all of the PAL system flags exist but the monitor cannot be used.

PAL USING MEMORY - REFORMAT

The AMP parameter allowing PAL to be stored in RAM memory has been enabled. This

changes the amount of RAM memory available for part program storage, requiring the RAM disk

to be reformatted. Part programs should have been backed up prior to this.

PARAMETER ASSIGNMENT SYNTAX ERROR

A block that assigns Paramacro parameters has been entered incorrectly.

PARAMETER NUMBER NOT FOUND

The AMP parameter number being searched for through the control’s patch AMP utility does not

exist in the system.

PARAMETER VALUE OUT OF RANGE

The value entered for the selected AMP parameter or paramacro parameter is less than or

greater than the allowed legal value.

PARENTHESIS INPUT ERROR

Parentheses have been entered incorrectly in a program block or calculation operation. Correct

the use of the parenthesis; verify they are in matched pairs.

PARITY ERROR IN PROGRAM

A serial communications error has occurred. A data parity error occurred while sending or

receiving data. This can result in a corrupted file, or the entire date transfer operation may be

aborted by the control.

PARK AXIS MOTION NOT ALLOWED

Axis motion was programmed for a parked axis in a dual axis group. When both master and

slave axes are parked, no axis motion is allowed on a parked axis in a dual group.

PART PROGRAM NOT SELECTED

An attempt was made to execute a program or check a program before a program was selected

for execution.

PART ROTATION FORMAT ERROR

In part rotation blocks (G68, G69), only plane changes and mode changes including inch/metric

and absolute/incremental are permitted. Any commands other than normal motion commands

and the motion G-codes (G00, G01, G02, and G03) are not permitted.

PASSWORD PROTECTED

When assigning password protectable features to an access level, an attempt was made to

assign a feature to a different access level when the currently active password does not have

access to the feature. You can assign features to other access levels only when you have

access to that feature yourself.

PEAK CURRENT NOT 300%

The axis for a 1394 or 9/440 is not AMPed to have the PEAK CURRENT set to 300%. This

misconfiguration forces the control into E--Stop.

PERIPHERAL DEVICE ERROR

An illegal communication attempt was made with a peripheral device, for example, attempting to

outpu

t to a tape reader or input from a tape punch.

PLANE SELECT ERROR

An attempt was made to change planes during cutter compensation (TTRC), between QPP

blocks, or between chamfer and corner rounding blocks. This error also will occur if G17 or G19

planes are selected on a lathe.

PLEASE WAIT FOR CLEARING OF PAL MEMORY

PAL is being erased in preparation for a PAL download.

PLUNGE MOTION NOT ALLOWED

The final plunge position must be different from the start point of the cycle. This message can

occur if the plunge axis is not programmed in the entry block to G89 mode, or if the plunge axis

increment is zero, or if the final plunge axis position is the same as the start point of the cycle

block during G89 mode.