Rockwell Automation 8520 9/Series CNC Integration Maintenance Manual Documentation Set User Manual

Page 751

Section 15A

Troubleshooting the Control

15A-41

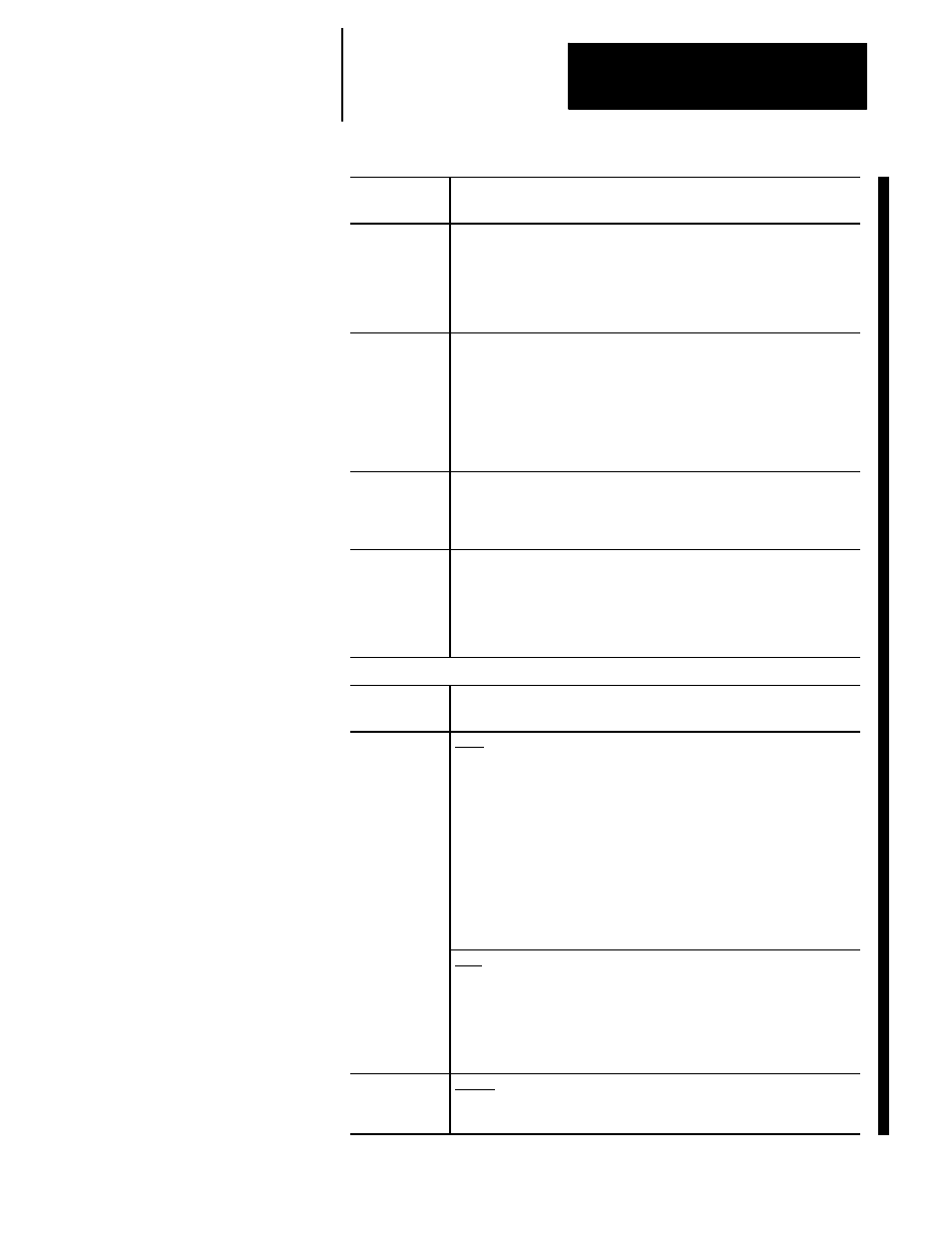

Faults

Axis Module

CNC display: Error Message

Description

GRND

FLT

Axix Module PowerFault (0:1,2,3,4)

The axis module hardware has faulted from a short duration over current

condition. If the output current exceeds a fixed level (Over 200% of axis

module rating for the 10 and 15 Kw modules and Over 300% for the 2, 3 and

5 Kw modules) this fault will appear. Typical causes are a shorted lead,

motor malfunction, or malfunctioning power IGBTs.

OVER

CRNT

Axis Module OverCurrent (0:1,2,3,4)

This axis module of your 1394 system has been requested to provide too

much current over an extended time period. This is typically caused by:

Accel/Decel command from the CNC is requiring peak current for an

excessive amount of time, the machine friction or inertial/viscous load is

excessive, the motor has been improperly sized, a short circuit exists across

the drive output terminals, logic supply circuits have malfunctioned, or AC

input is incorrectly wired.

BUS

FLT

Axis Module Buss Voltage Loss (0:1,2,3,4)

The DC bus supply to the axis module was lost or has fallen below 275VDC.

Check slider connections/termination strip or there could be a blown link fuse.

This condidtion also occurs in a systemE--stop state.

OVER

TEMP

1

Axis Module OverTemp (0:1,2,3,4)

The 1394 axis module contains a thermal sensor which senses the internal

ambient temperature. Causes could be: that the cabinet ambient

temperature is above the 70 degree C rating. The machine duty cycle

requires an RMS current exceeding the continuous rating of the axis module.

The airflow access to the 1394 is limited or blocked.

Faults

System Module

CNC Display error message

Description

BUSS

VOLTAGE ____

HIGH :

System Module Over Voltage (0)

The 1394 system module bus voltage exceeds the maximum operating

voltage. The DC power bus is continuously monitored. If it exceeds a preset

level (810 Vdc), an over voltage fault is sensed and the axis modules are

disabled. This can be caused by an under sized shunt requirement, shunt

regulator fuse has blown, the shunt regulator transistor has malfunctioned,

the power driver board is malfunctioning and incorrectly sensing the bus

voltage, the CNC acc/dec rate is incorrectly set, the input line voltage is

excessive, the system inertia is too high causing excessive energy to be

returned to the power supply bus, or a vertical axis with insufficient

counterbalancing is overdriving the servomotor and causing excessive

energy to be returned to the power supply bus.

LOW :

System Module Under Voltage

The 1394 system module voltage does not meet the minimum operating

voltage. The DC power buss shall activate the under voltage limit when the

bus drops to 275 VDC or less. It will clear at 300 Vdc. Typical causes

include low voltage on the three phase input. If any Phase is missing, the

“PhaseLoss”message will take priority.

BUSS

VOLTAGE ____

VALUE : Displays the value of the DC buss voltage in DC volts. Nominal

normal voltage is 600 V