Bayer HealthCare Rapidlab 800 User Manual

Page 265

3Ć93

Maintaining the System

CAUTION:ĄĂ

Do not turn the needle valve too hard or damage can occur.

h. Carefully turn the needle valve adjustment knob counterclockwise until

until it stops.

i. Listen carefully for any gas leaks.

j. Check the gas line for good gas flow.

k. Visually check for leaks by applying soapy water around all connections, as

shown in Figure 3-63, and watching for bubbles.

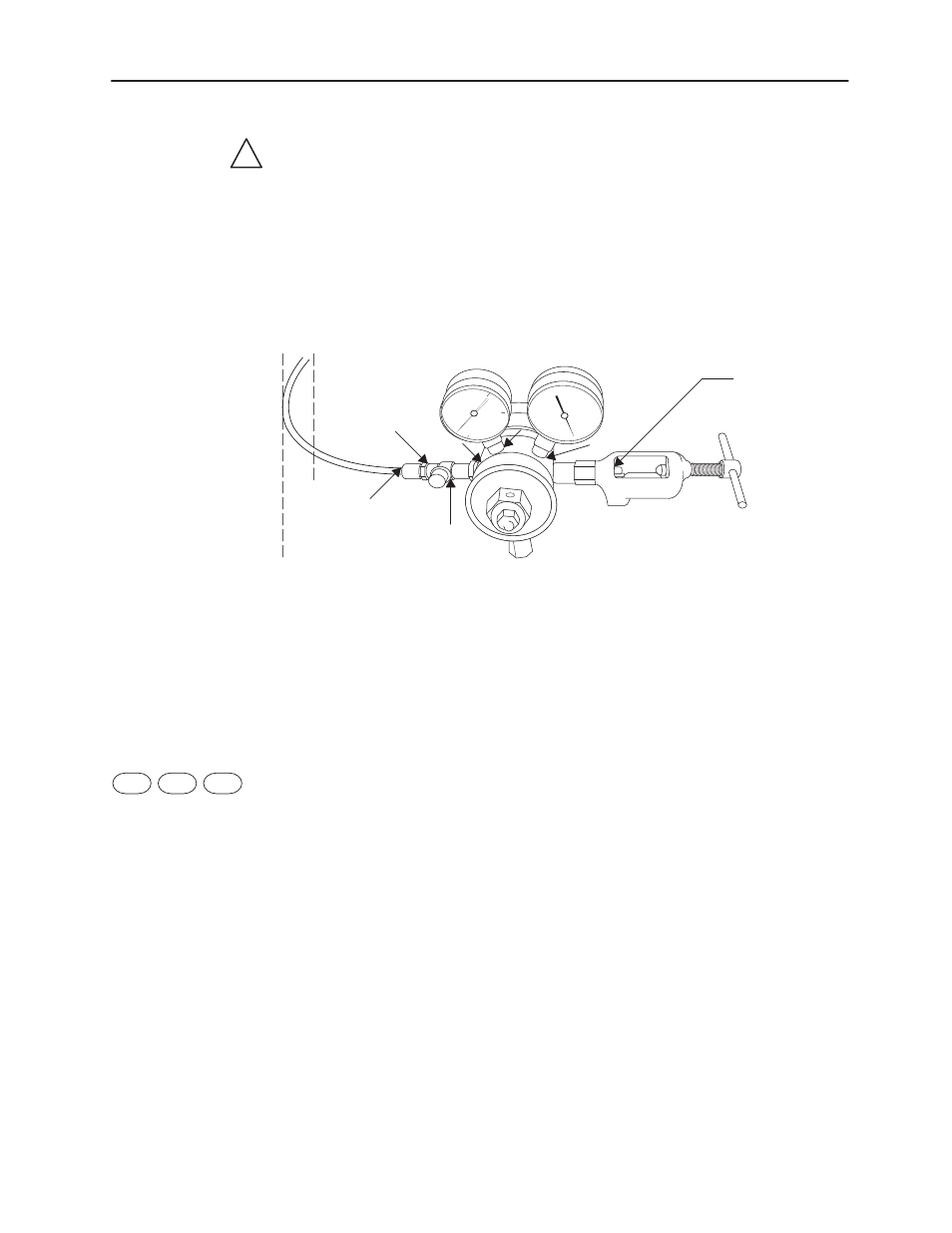

Figure 3Ć63.āăChecking Connections for Leaks

Apply soapy water

to all connections

indicated by arrows

5.

If the 800 system will not be used for an extended period of time, close the gas

tank by turning the valve stem clockwise.

6.

Connect the gas line to the appropriate 800 system port.

7.

Press

Continue

.

A wash sequence starts. When the wash sequence finishes, a message box

appears prompting you to perform a two-point calibration.

8.

Check the gas flow rate from the Menu screen:

a. Select

3 Troubleshooting

and press

Enter

.

b. Select

1 Fluidics System

and press

Enter

.

c. Select

4 Valves

and press

Enter

.

d. Select the gas type that you replaced and press

Enter

.

e. Insert an aspiration adapter into the sample port and immerse the open end

of the adapter into a small container of reagent water.

f. Press

Start Test

.

g. Verify that a steady stream of bubbles flows into the water.

h. Press

Stop Test

.

i. Verify that the bubbles stop flowing into the water.

j. Remove the adapter.

k. Press

Exit Test

.

!

4

1

Menu Code

3

(from the Main Menu)