5) analyzer base sampling unit (gcsmp) – Yokogawa GC8000 Process Gas Chromatograph User Manual

Page 58

<1. Overview>

1-31

IM 11B08A01-01E

11/03/22

15:15:45

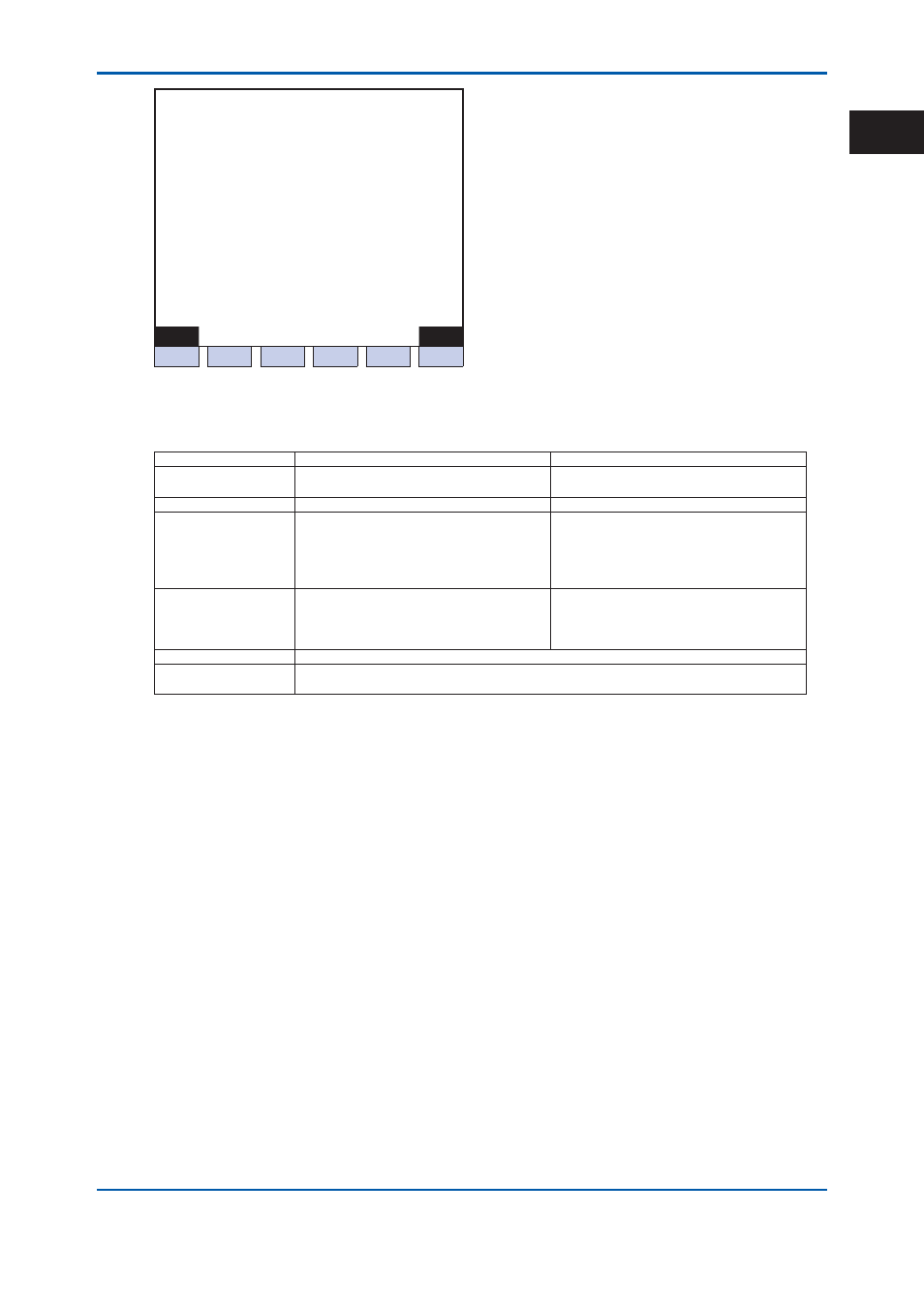

Temperature Setup

Oven #1

- Oven max temp

145.0 °C

- Oven temp setpoint 130.0 °C

- LSV temp setpoint

1***** °C

> - FPD temp setpoint

30.0 °C

Menu

Menu

Menu

Menu Oven# Oven#

F1

F2

F3

F4

F5

F6

Figure 1.11

Example of the operation condition confi guration screen of the GC-HMI (touch panel)

EtherLCD

Table 1.1

The maximum number of parts for each oven

Large isothermal oven

Isothermal oven

Pressure regulator for

carrier gas

Max. 2

Max. 2

Restrictor

Max. 6

Max. 6 (4 recommended)

RV

LSV

Atmospheric-pressure

balancing valve

Max. 8 in total

Select from:

7 RVs, 1 LSV, 2 Atmospheric-pressure

balancing valves

Providing RV + LSV ≤ 7

Max. 7 in total

Select from:

5 RVs (3 recommended), 1 LSV, 2

Atmospheric-pressure balancing valves

Providing RV + LSV ≤ 5

Detector

Max. 2 in total

Select from:

2 TCDs, 2 FIDs, 1 FID-MC, 1 FPD

Max. 2 in total

Select from:

2 TCDs, 2 FIDs, 1 FID-MC

*FPD is not mountable.

Mesh arrester

Max. 2 (used for FID and FPD)

Flame arrester

Max. 5

(Connections for sample gas, carrier gas, utility gas, and I/O of the detector)

(5) Analyzer Base Sampling Unit (GCSMP)

In order to ensure the process gas chromatograph operates stably over a long period of time, it

is necessary to select the most appropriate sampling system corresponding to sample properties

in addition to analyzer stability and reliability. The GCSMP can be equipped on the self-standing

GC8000 Type 1 and 2, in which the analyzer and GCSMP can be operated and maintained

integrally.

The GCSMP adjusts the pressure and fl ow rate of the measurement stream for measuring the

process sample (gas and liquid) and the calibration and validation stream with standard gas

(liquid). The GCSMP also has a humidifying and warming function (setting temperatures: 50°C

or 75°C) and stream switching function by using air output from the analyzer. If the GCSMP is not

equipped, the stream switching valve can be operated by sending the air output or contact output

to an external sampling system.

2nd Edition : May 11, 2012-00

1