Caution, Gland assembly – Yokogawa GC8000 Process Gas Chromatograph User Manual

Page 389

<6. Maintenance>

6-36

IM 11B08A01-01E

CAUTION

The isothermal oven is extremely hot after turning off the power immediately. Keep the purging

air supplied for more than an hour after turning off the power. Keep hands away from the oven

components.

(6) Turn off the supply of the purging air and carrier gas. For a detection system with an FID,

turn off the supply of hydrogen (or nitrogen) gas and combustion air as well.

(7) Open the control unit door using a key included in the accessory kit.

(8) Remove the couplings connected to the rotary valve. When removing the couplings, label

them for ease of identifying the connections later. The rotary valve is either a single-sleeve

or double-sleeve type, depending on the specifi cations. Each type comprises four to six

pipes extending from the sleeve.

(9) Remove the two screws which are not painted with red enamel to disassemble the rotary

valve. Do not touch the two screws which are painted red.

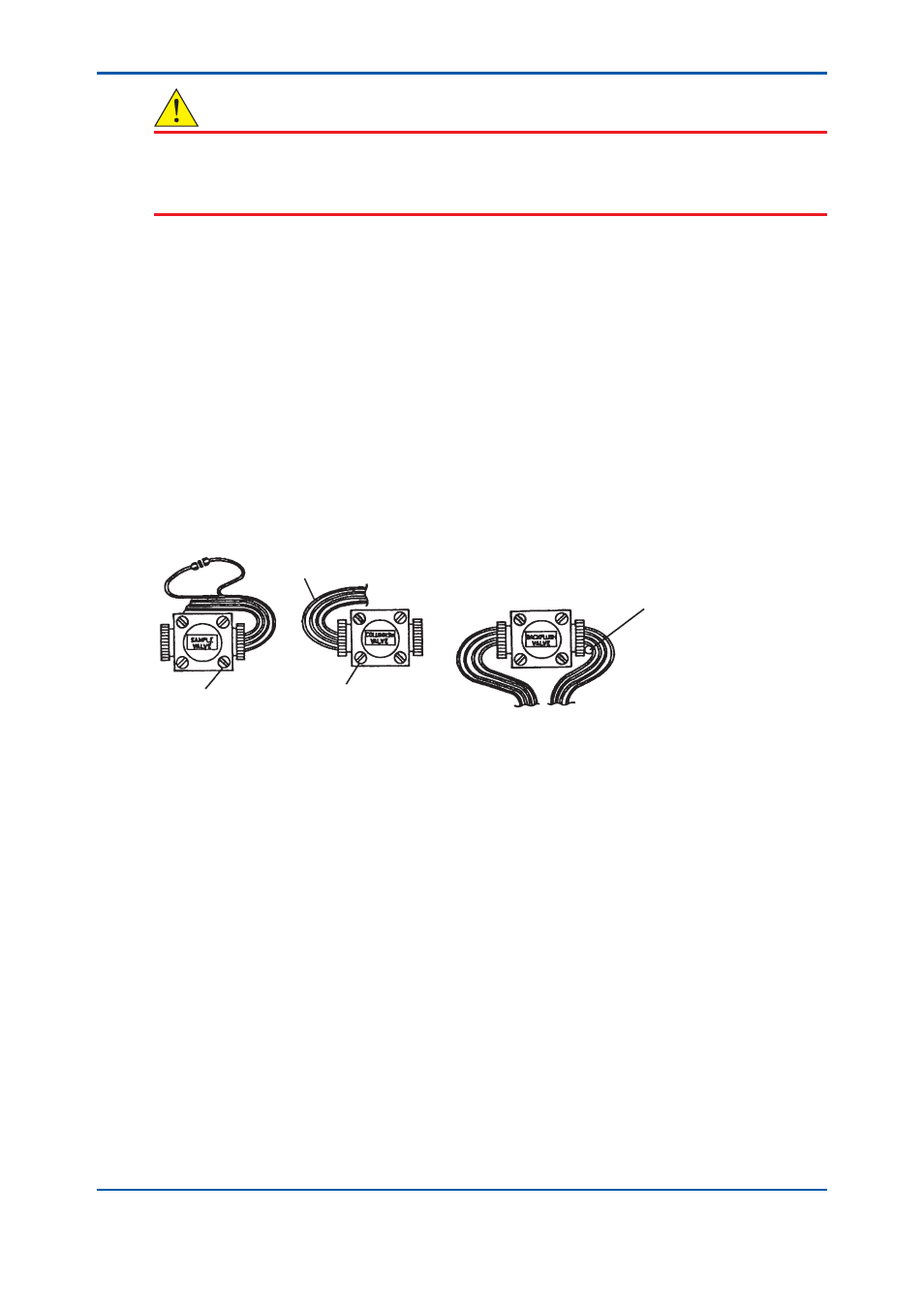

(10) Install a new rotary valve. When installing it, it is necessary to bend pipes as shown in Figure

6.31. When bending a pipe, use another pipe that is approximately 10mm in diameter to

support it and avoid excessive force applied on the root of the pipe. The cap nuts at the tip of

the pipes are inscribed with numbers. Engage these cap nuts according to the pre-labeled

numbers or per column system diagram in the operation data.

(11)

Perform a leak test on the piping.

F0231.ai

ø10 mm pipe

Rotary valve

mounting screws

ø1.6 mm tubes

Do not loosen the screws

with red enamel paint.

Sample valve

Column switching valve

Backflush valve

Figure 6.31

Replacing rotary valves

Gland assembly

See Figure 6.32.

(1) Stop the operation. (See “3.3.4 Stopping operation” for this procedure).

(2) Turn off supply of the sample.

(3) If the sample is liquid, purge the sample line with the purge gas (nitrogen gas or instrument

air).

• When the stream switching valve is a pneumatic valve, change the analyzer status to

Manual and turn on the stream switching valve on the sample line to let the purge gas fl ow

in.

• When the stream switching valve is a stop valve, close all the stop valves and open the stop

valve on the sample line to let the purge gas fl ow in.

(4) Close all the stream switching valves.

2nd Edition : May 11, 2012-00