1 parts for the protection system – Yokogawa GC8000 Process Gas Chromatograph User Manual

Page 357

<6. Maintenance>

6-4

IM 11B08A01-01E

(3) When cleaning inside of a pipe, do not use any solvent containing non-volatile impurities, as

they will contaminate inside of the pipe and will prevent normal analysis. This contamination

might necessitate parts replacement to restore the system to normal.

When the pipes need to be cleaned, use highly-pure acetone.

(4) After replacing piping parts, always perform leak tests.

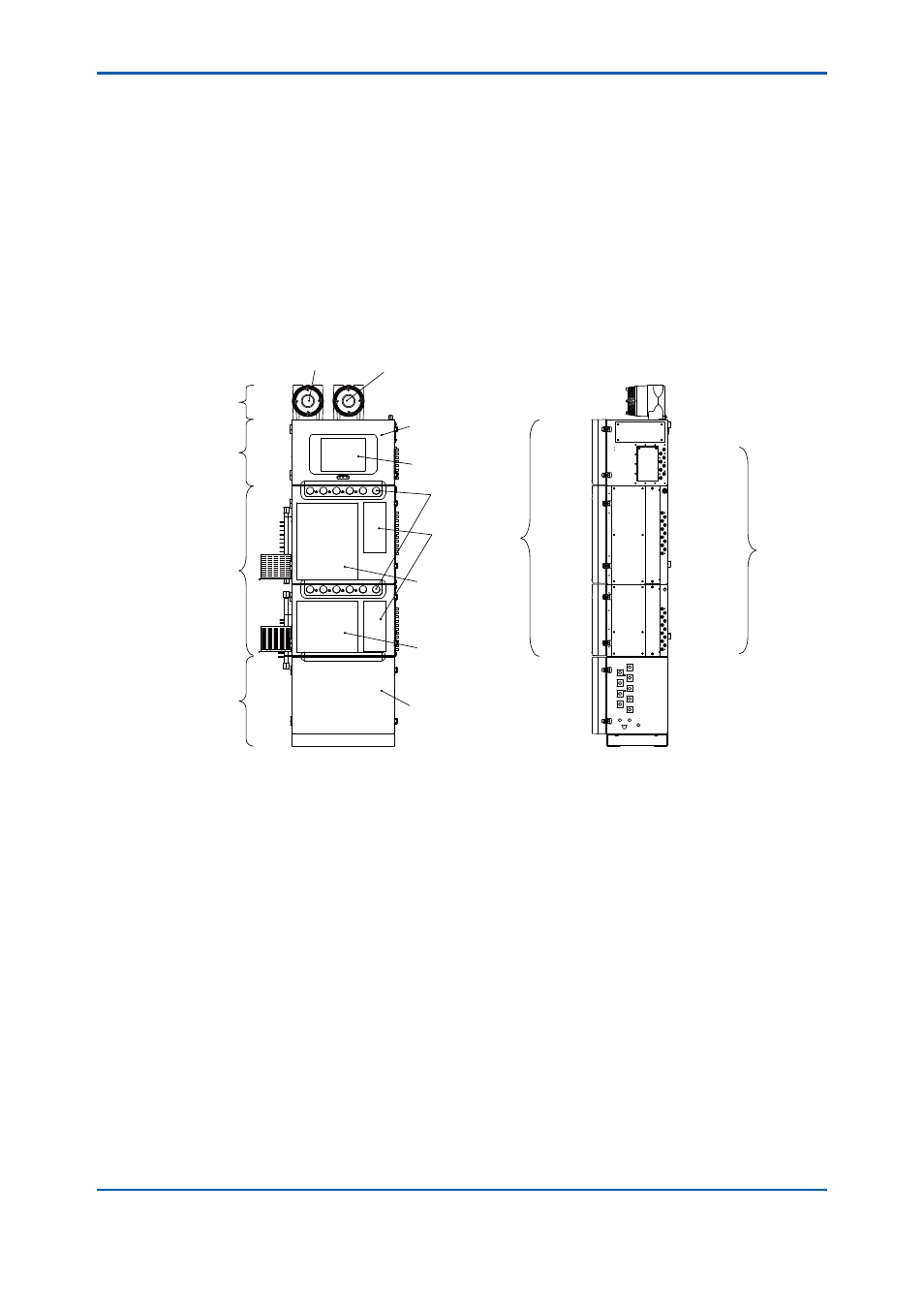

This section shows the replacement procedures for the maintenance (replacement) parts that are

used in the following sections of GC8000.

1. Protection system

2. Electronics section

3. Pressure and fl ow control section

4. Isothermal oven

5. Sample processing section (GCSMP)

Protection system A

(2)

Control Unit

Electronics

section

(1)

Protection System

(2)

Electronics section

(4)

Isothermal Oven

(5)

Sample Processing

Section

Oven Unit 1

Electronics

section

Oven Unit 2

Electronics

section

(3)

Pressure

and Flow

Control

Section

Control Unit

Pressure and

Flow Control

Section

Oven Unit 1

Pressure and

Flow Control

Section

Oven Unit 2

Pressure and

Flow Control

Section

Protection system B

Control Unit

Analyzer Base

Sampling Unit (GCSMP)

Display

(3)

Pressure Control

Section

(2)

EPC Box

Oven Unit 1

Large

Isothermal Oven

Oven Unit 2

Isothermal Oven

Figure 6.1

Confi rm the location of each replacement part referring to Figure 6.1.

6.2.1

Parts for the Protection system

The instructions for replacing parts in the protection system are explained.

(1) Pressure switch

(2) Fuse

(3) Relay and Relay board

There are 2 types of protection systems depending on type of GC8000, as shown in Fig. 6.2. No

enclosure is mounted for FM/CSA explosionproof Y-purge type.

2nd Edition : May 11, 2012-00