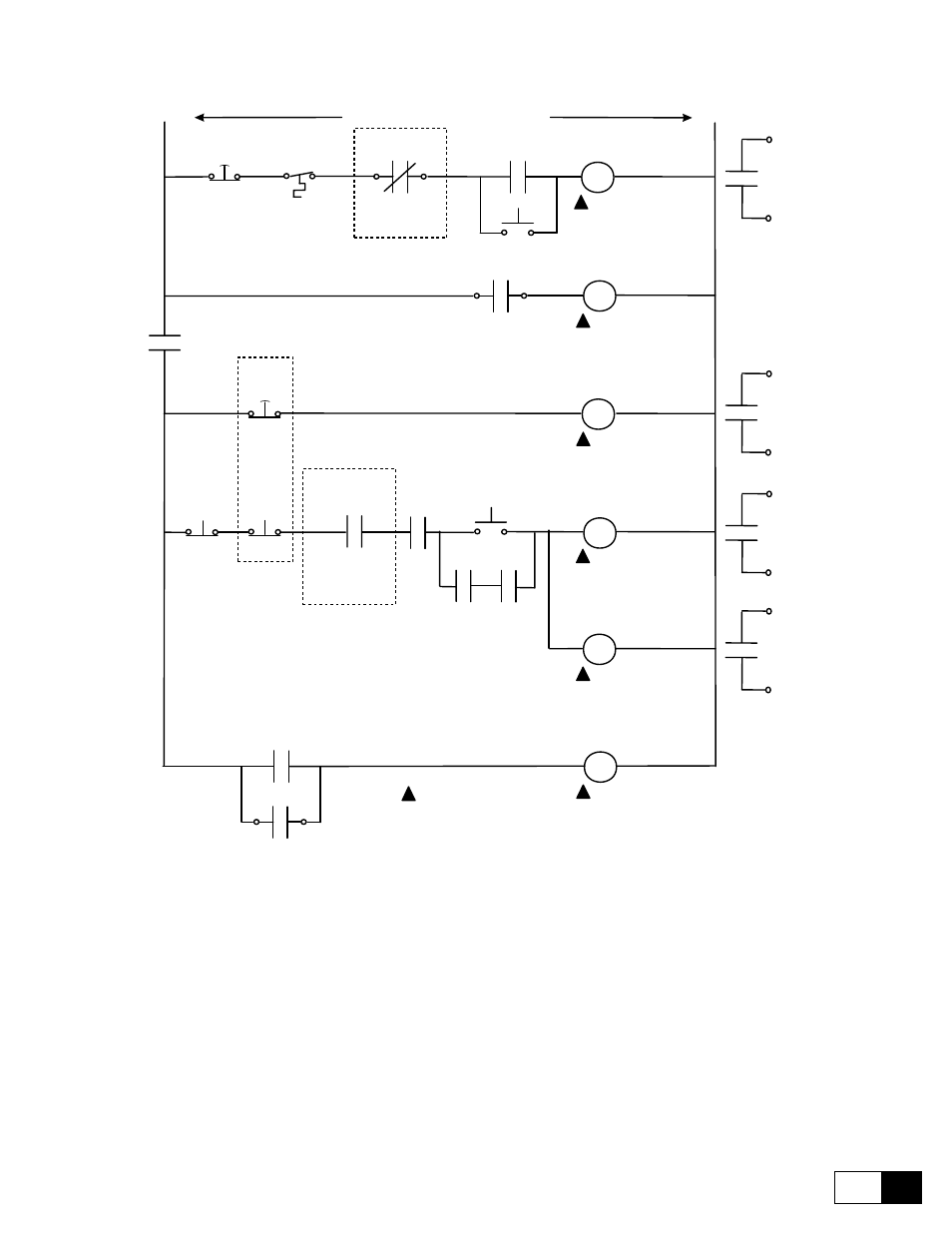

Figure 4.8.2: example for relay interface – GE Industrial Solutions DV-300 DC Drive Users Manual User Manual

Page 63

DV-300 Adjustable Speed Drives

——— WIRING PROCEDURES ———

4

19

Coil Suppressor

AC Input Contactor

K1M

ENABLE

K1MX

Drive OK

Contact closes

with power ON

FAN 560A and

above only

START

K2

FAST STOP

Drive OK

Reset

115 VAC from CPT

fed from AC incoming

START

PB

START

K2

FAN power

OK (Q1)

STOP

PB

85

86

FAST STOP

K0

Drive Healthy

picks up if OK

SNF

P.B.

latched on push, pull to reset

after the process has stopped

H

N

EXTERNAL

ESTOPS

System Not Fault

SNF

SNF

EXTERNAL

RUN

PERMISSIVES

T.D.A.D. *

- Time delay after de energization -

Set greater than the maximum

decel ramp time.

K1MX

K2

K0

SNF

19

15

19

14

19

13

19

12

+24V

+24V

+24V

+24V

EXT

FAULT

FAST

STOP

START

ENABLE

75

76

Operation set by parameter [629]

RELAY 2 and parameter [626] stop mode

K1M AUX

(MA AUX)

81

82

Blown

Fuse

560A and

above only

DV-300

Relay 2

K2

Figure 4.8.2: Example for relay interface

n

ote

!

1 - ENABLE must remained energized during a normal STOP or FAST STOP for the DV-300

to decel on a ramp.

2 - ENABLE must be de energized to power up and to reset a fault or alarm.

3 - If the external fault input, or fast stop input, is unused, the unused input must

be tied to + 24V (terminal 19).

4 - EXTERNAL FAULT input, FAST STOP input, START input and ENABLE input

need picked up during LAN operation. Opening the input will cause labeled drive

reaction.

* - T.D.A.D. = Time Delay After De energization.