8 brake control – GE Industrial Solutions DV-300 DC Drive Users Manual User Manual

Page 251

DV-300 Adjustable Speed Drives

——— FUNCTION DESCRIPTION ———

6

123

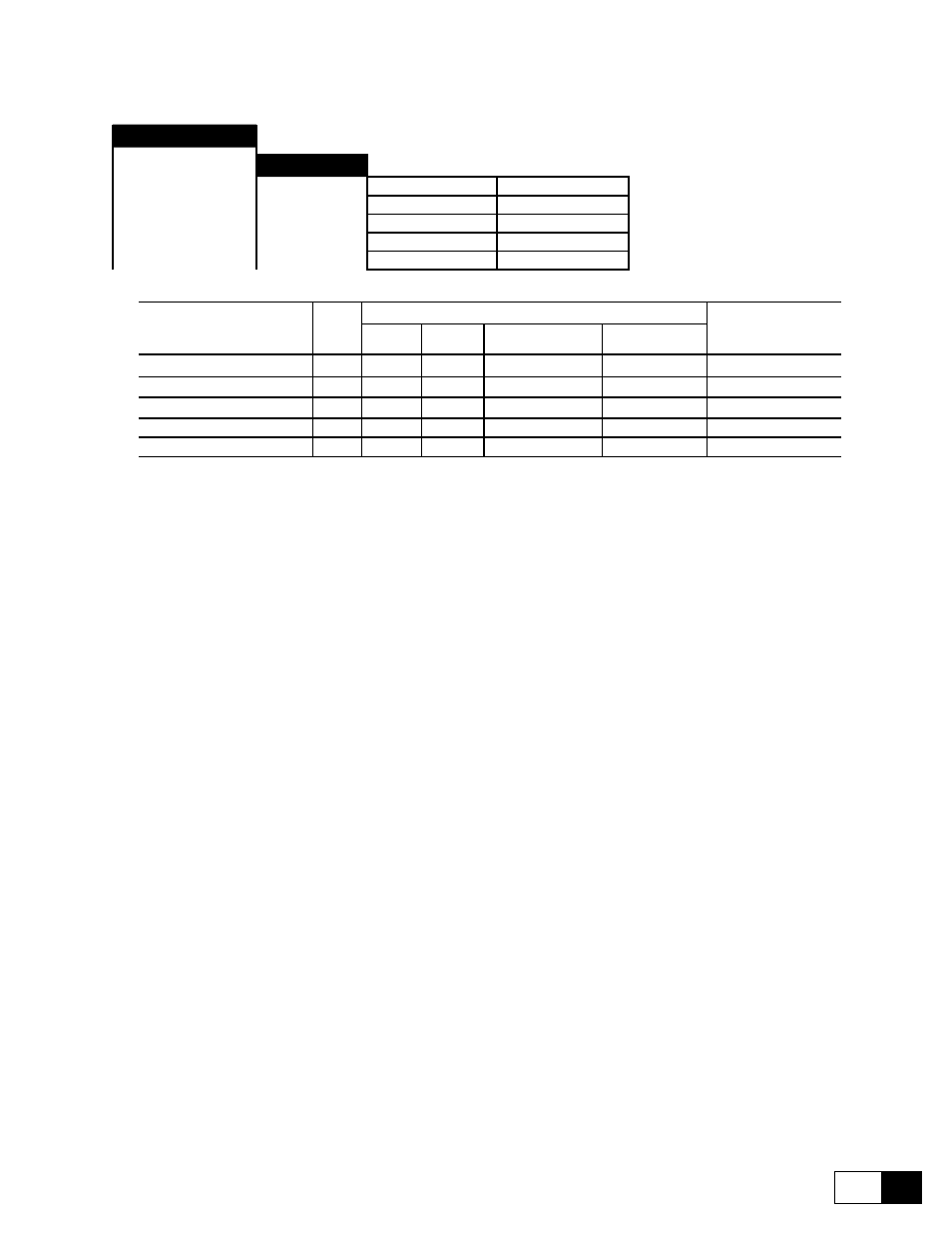

6.14.8 Brake control

FUNCTIONS

Brake control

[1295]

Enable Torque pr

[1262]

Closing speed [rpm]

[1293]

Torque delay [ms]

[1294]

Torque proving [%]

[1266]

Actuator delay [ms]

Parameter description

No.

Value

Standard

Configuration

min

max

Factory

American

Factory

European

Enable Torque pr

1295

0

1

Disabled

Disabled

-

Closing speed [rpm]

1262

0

200

30

30

-

Torque delay [ms]

1293

0

30000

3000

3000

-

Torque proving [%]

1294

0

200

75

75

-

Actuator delay [ms]

1266

0

30000

1000

1000

-

The purpose of this function is to ensure that the machine develops a torque which is capable of supporting the

load of a crane or hoist during the transient brake release phase, in any direction.

Enable Torque pr

Enables the brake control function, making it possible to apply the torque capable of

supporting the load during the transient brake release phase.

Closing speed

After the stop command, this parameter sets the motor speed at which the “Brake con-

tactor control” digital output is disabled.

Torque delay

The time, after the start command, within which the brake released feedback must be

received. If the transient phase is not completed within the time limit set in this parameter,

the “Brake error” alarm condition is signalled. In the closing phase the Torque delay is

set to 1 second.

Torque proving

Current capable of supporting the load the drive must guarantee before the brake is

released (as a percentage with respect to FLC). It can be set from a parameter and from

an analog input set as Brake Ref (32).

Actuator delay

Delay at the end of the transient release phase, from receiving the signal to confirm that

the brake has been released until the motor actually starts to run.