GE Industrial Solutions DV-300 DC Drive Users Manual User Manual

Page 270

GEI-100332Ga

——— FUNCTION DESCRIPTION ———

6

142

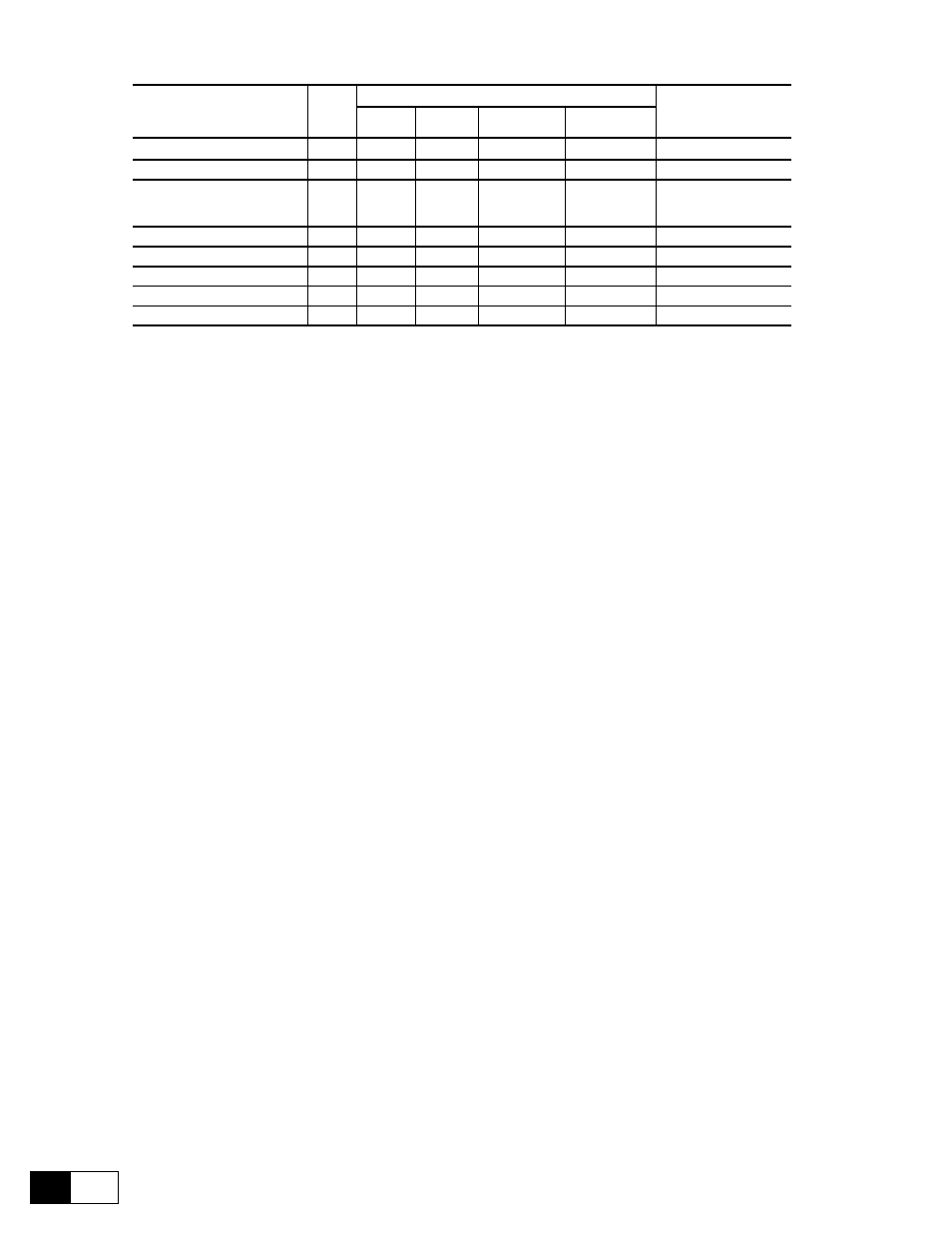

Parameter description

No.

Value

Standard

Configuration

min

max

Factory

American

Factory

European

PID error

759

-10000

+10000

0

0

PID feed-back

763

-10000

+10000

0

0

**

PID offs. Sel

Offset 0 (0)

Offset 1 (1)

762

0

1

0

0

*

PID offset 0

760

-10000

+10000

0

0

**

PID offset 1

761

-10000

+10000

0

0

PID acc time

1046

0.0

900.0

0.0

0.0

PID dec time

1047

0.0

900.0

0.0

0.0

PID clamp

757

-10000

+10000

10000

10000

* This function can be set on a digital programmable input.

** This parameter can be set on an analog programmable input.

PID error

Error reading in the input of the function PID (PID clamp block output).

PID feed-back

Reading of feed-back value from the transducer position (dancer) or tension (load cell).

PID offs. sel

Offset selector added to PID feed-back. This parameter can be set on a digital program-

mable input.

0 = PID offset 0 1 = PID offset 1

PID offset 0

Offset 0 added to PID feed-back. This parameter can be set on analog input , E.g. for

the tension setting when a load cell has to be used as feed-back.

PID offset 1

Offset 1 added to PID feed-back.

PID acc time

Acceleration ramp time value in seconds after the PID offset block.

PID dec time

Deceleration ramp time value in seconds after the PID offset block.

PID clamp

The clamp allows a smooth tension setting of a controlled system winder/unwinder,

when the “calculation of the initial diameter” function cannot be used.

When the drive is enabled, the dancer is at its lower full scale, with PID error at its

maximum value. The motor could accelerate to fast in taking the dancer in its central

position of work.

Setting PID clamp at a value sufficiently low e.g = 1000, at the drive enabling and at

the enabling of Enable PD PID, the value of PID error is limited to 1000 until the

signal coming from the dancer (PID feed-back) does not reach this value. Now PID

clamp is automatically take back at its maximum value corresponding to 10000. The

clamp is kept at 10000 till the next disabling of the drive or of Enable PD PID.

The feed - back input is provided for the analog transducers connection like dancer, with relative potentiometer

or load cell. Nevertheless, it is possible to use this input block as comparison point between two different analog

signals + / - 10V.

Connection to a dancer with potentiometer connected between - 10 and + 10V.

The cursor of the potentiometer can be connected to one of the analog inputs of the drive. Normally it should

be used the analog input 1 (terminals 1 and 2) because it is provided with filter.

The input choosen for that connection must be programmed in the menu I/O CONFIG as PID feed - back. Its

value can be read in the PID feed - back parameter in the PID REFERENCE submenu.

Through PID offset 1 (or PID offset 0), it is possible to carry on the adjustement of the dancer position.